V-COIL Wire thread insert Screw locking type SL M 8 x 1.25 - 1.5 D (100 pcs.)

Item no.

05311

€0.29

in stock - more than 10.000 pieces available

Application

Application:

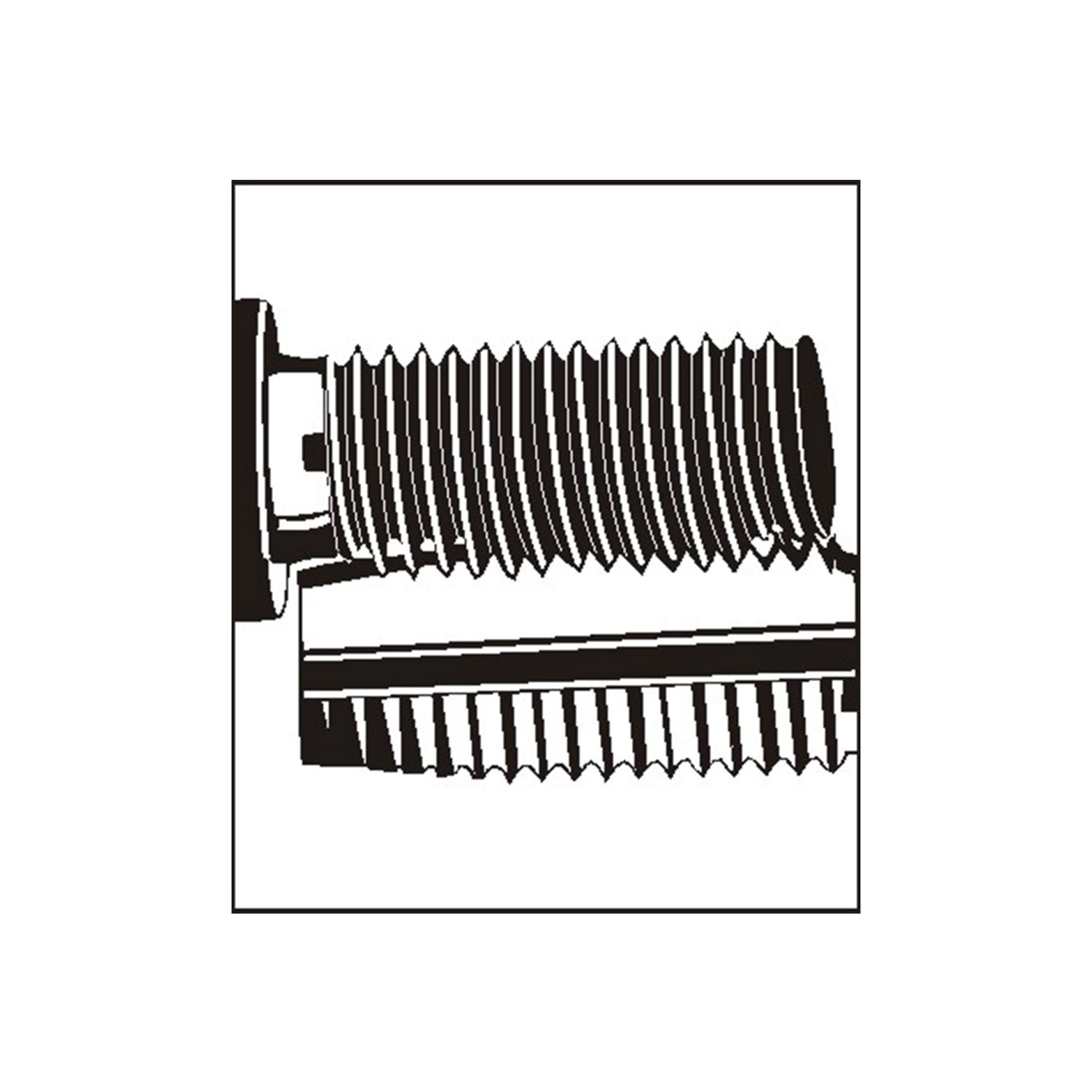

- Thread Repair of damaged or worn-out threads

- Thread Armour Plating for material with low shear strength

- Recovery of rejected items

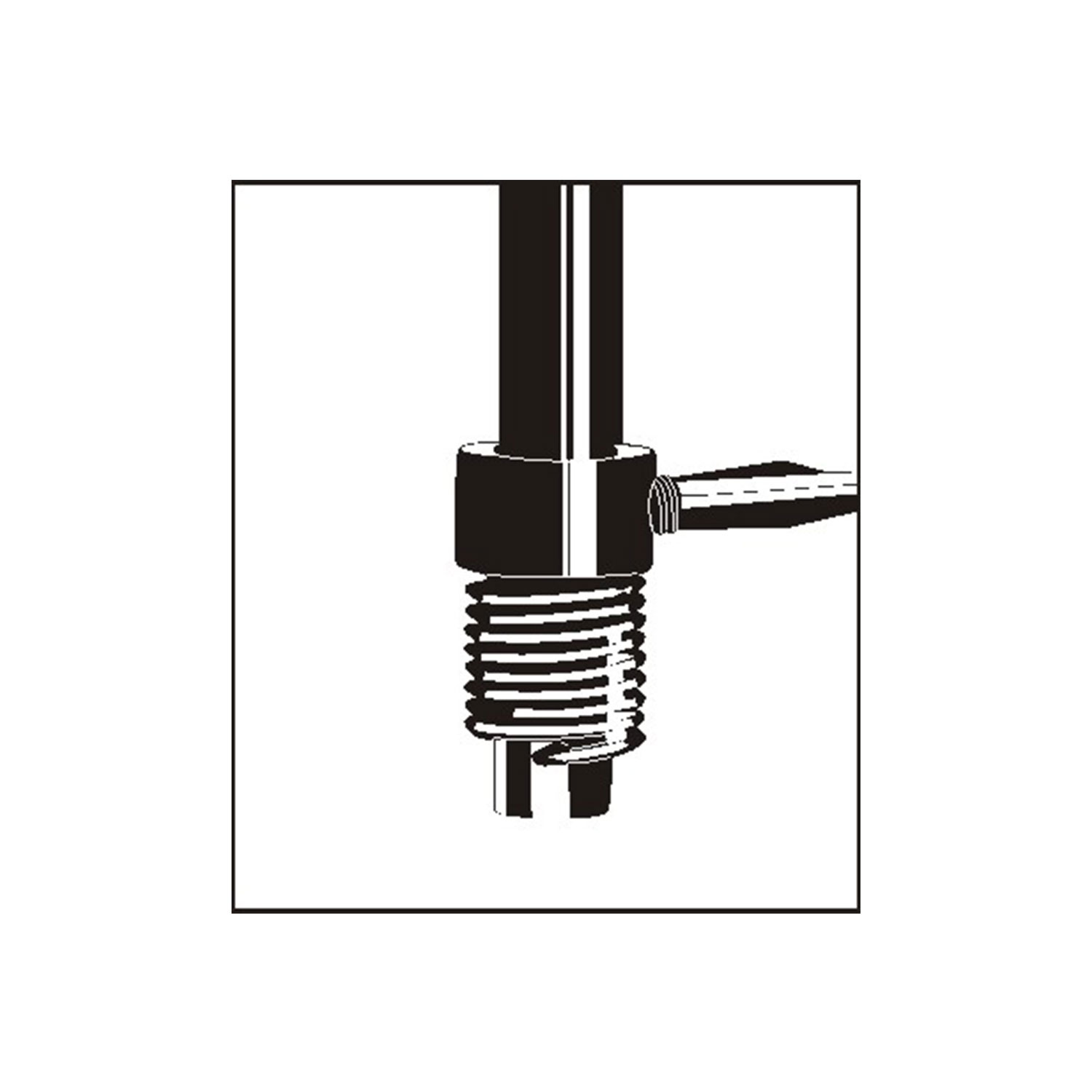

- provided for applications with effects of cyclic vibration or impact

- only close fit plated or lubricated bolts or screws are used with screw locking inserts Type SL

Advantages:

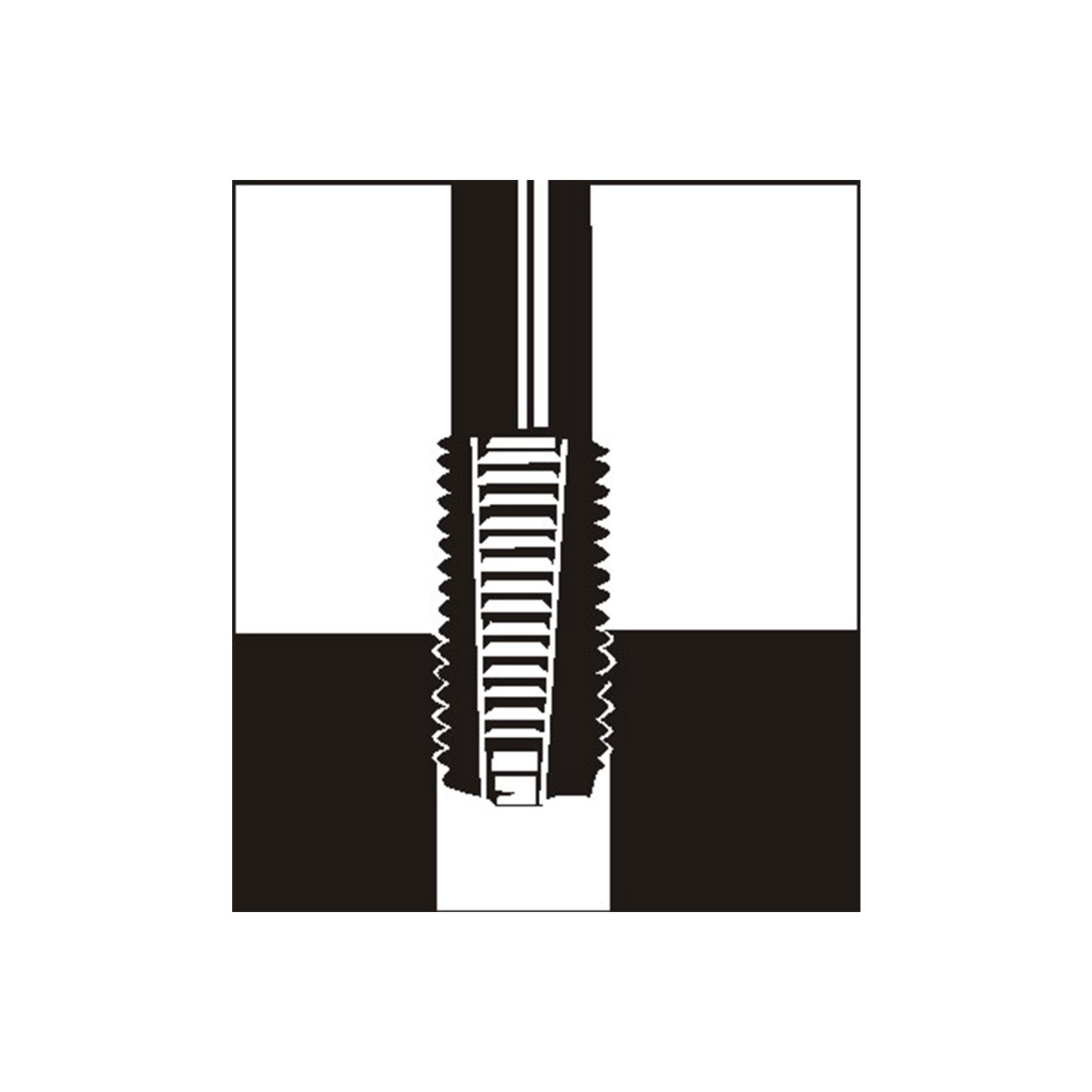

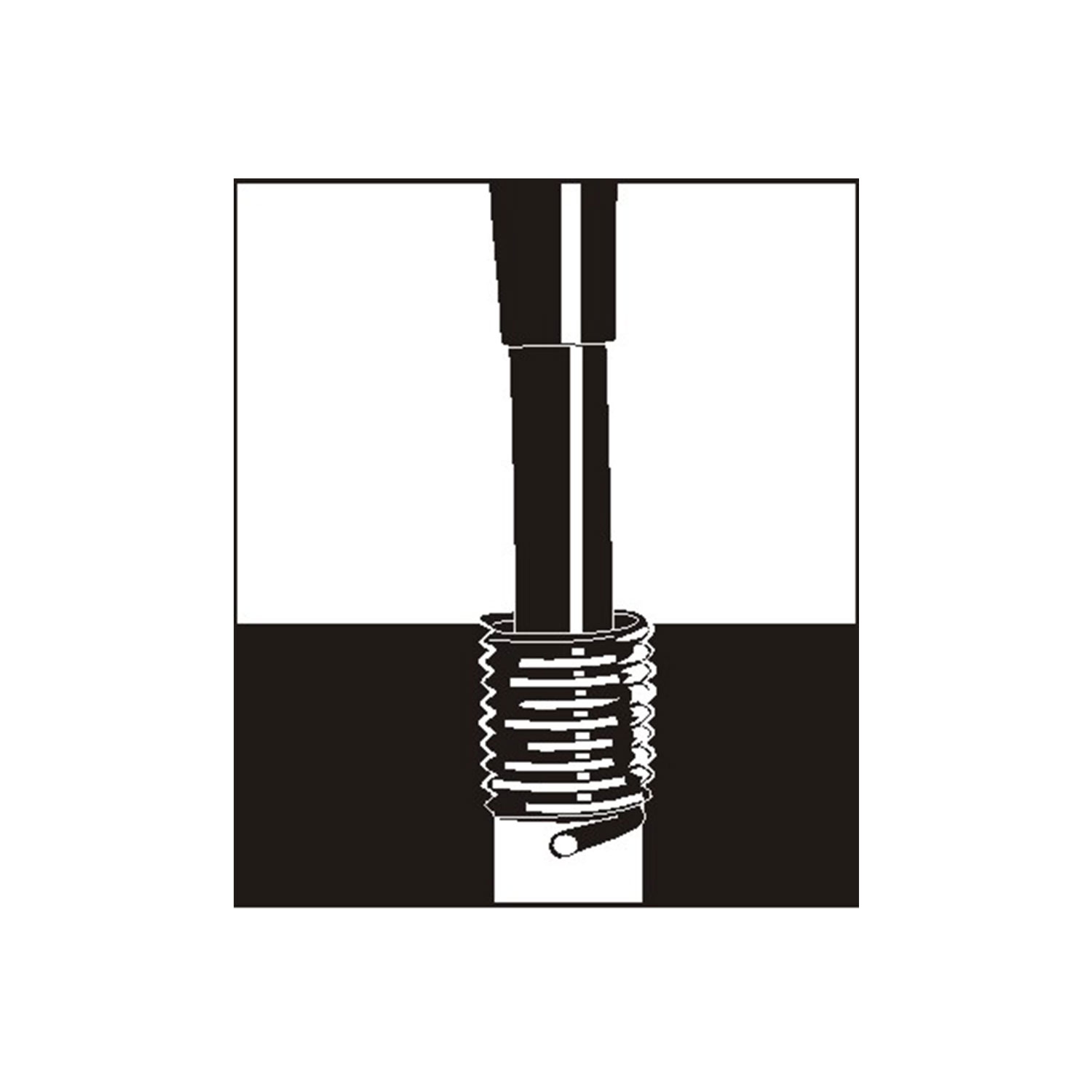

- produced from precision profiled austenitic stainless steel wire wound into a helical spiral

- spring like appearance

- for high strength and long-lasting internal threads

- higher temperature and corrosion resistance

- higher load capacity after the repair by better thread properties

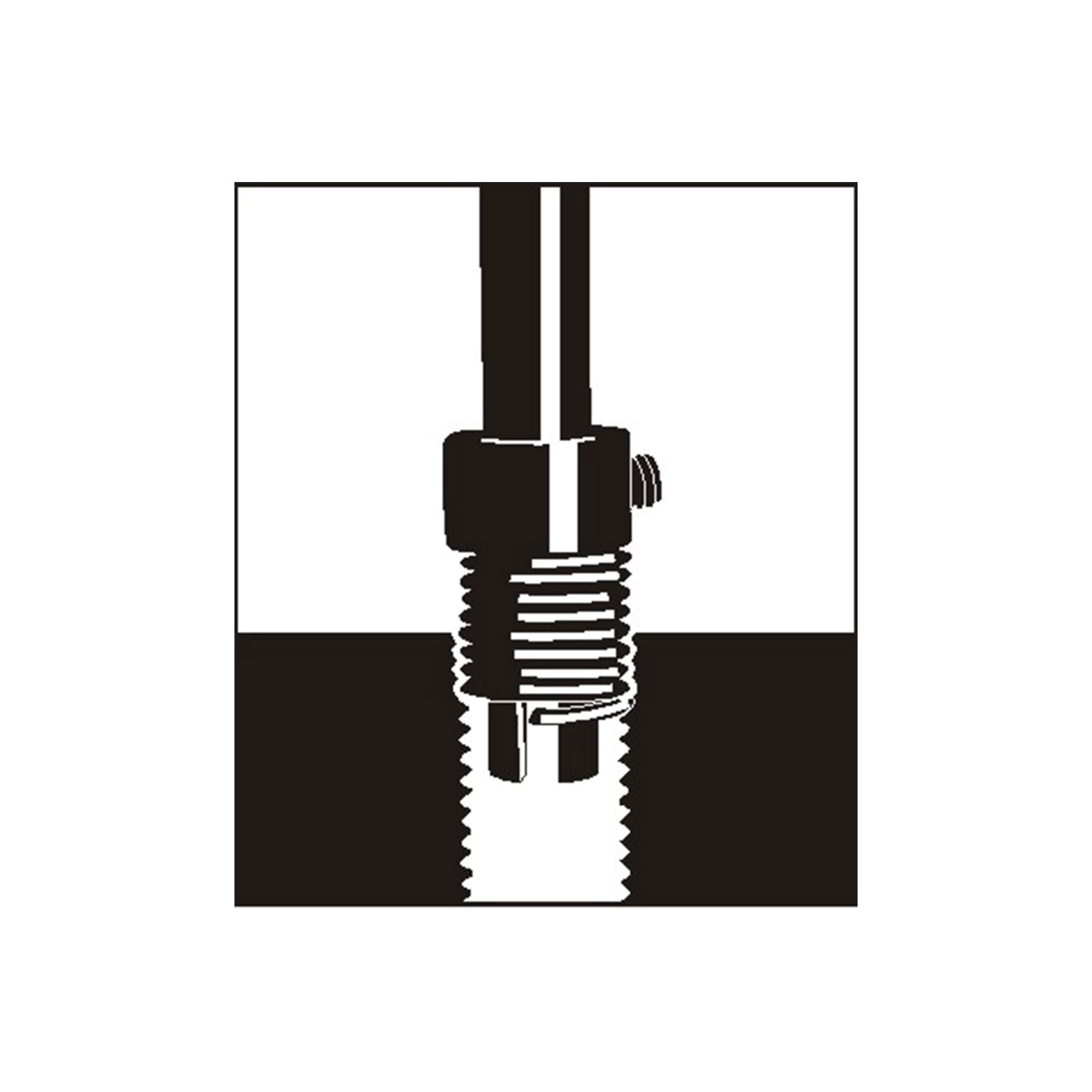

- additional security of prevailing locking torque

- can generally be incorporated into existing designs where no previous provision has been made

- position is maintained by the action of radial pressure between their coils and the flanks of the tapped hole

Operation:

One or more polygonal grip coils press exert radial pressure on the male thread. Each grip coil consists of a number of tangential locking chords which protrude inside the minor diameter of the normal free running coils. As the male thread passes through these grip coils, the locking flats are displaced thus exerting radial pressure or prevailing torque on the male thread. On removal of the male thread, the locking coils relax to their original forpermitting repeated assembly whilst retaining a measurable level of prevailing torque.

Additional information

| Type of thread | metric ISO-thread |

|---|---|

| Standard | DIN 8140 |

| Material | from stainless steel |

| Tolerance | ISO2 (6H) |

| Size | M 8 x 1.25 |

| Length | 1.5 x D |

| Packaging unit (piece) | 100 |

| EAN | 4022835053118 |

| Item number | 05311 |

| Thread standard | DIN 13 |

| Packing unit (pcs.) | 100 |