Round Dies VX – THE premium cutting tool from VÖLKEL

When producing an external thread on a workpiece, a round die is usually used. This is often operated by hand with a suitable holding tool (die stock). Many of you will know this method and have probably seen it many times.

The Round Dies VX from VÖLKEL offer additional added value for the user. Because the dies are not only designed for manual use, they are also ideally suited for machine applications. We will demonstrate a practical application in our next article. Here, we will first introduce you to the features of the VX series.

The Round Dies VX from VÖLKEL offer additional added value for the user. Because the dies are not only designed for manual use, they are also ideally suited for machine applications. We will demonstrate a practical application in our next article. Here, we will first introduce you to the features of the VX series.

Advantages of the Round Dies VX

The dies made of HSSE offer many other advantages in addition to the possibility of machine use.

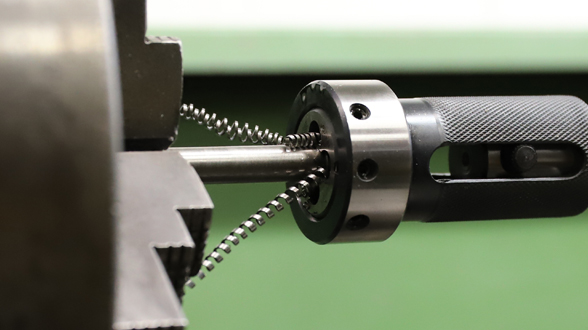

The gun nosed chamfer causes an intentional controlled chip removal into the cutting direction and a reduction of the cutting torque. This optimal chip removal improves the surface quality of the cutted thread. A plugging of the chip holes is avoided and there is a significant increase in the running life of the application.

Furthermore, the dies from our VX series are lapped. This means that the surface roughness of the cutting tool is reduced by means of a further production step. This results in a better and easier cut during use and the surface of the thread is also optimized. The lapped design also allows a more accurate work when using the die by machine.

The steam tempered surface leads to a better adhesion of the coolant and lubricant. This reduces the risk of the lubricant film breaking off and it avoids cold welds forming in the thread of the die.

Application range

The Round Die VX serves a wide range of materials in which it can work optimally and cut threads with absolute precision. These include, for example, alloyed tough-hard and difficult-to-cut materials up to 1,200 N/mm², stainless steels, aluminum and nodular cast iron (GGG).

Our VX series includes metric sizes up to M 30, many metric fine sizes up to M 24 and also pipe threads (G) up to 1 inch.

Also available is a seven-piece set in a metal case (M3-12).