Round Dies MS – THE brass specialist from VÖLKEL

If a standard die is used to produce an external thread in short-chipping materials (such as brass or bronze), it can very easily lead to chip removal not working properly. This results in an insufficient thread quality. The reason for this is most likely that the rake angle is not optimal and the die therefore engages too strongly in the material.

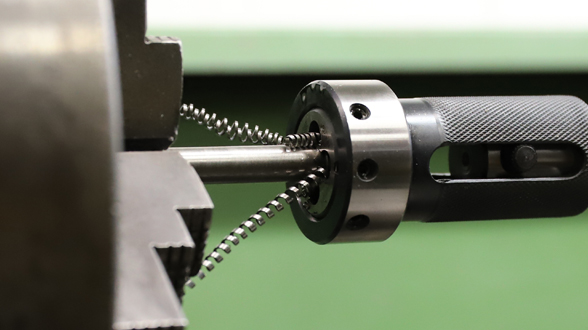

The round dies MS from our production have a flatter rake angle and are also lapped. This makes them ideal for short-chipping materials. Below you will find more features of our MS series and also a short video of an application with a die holder in a bench. The bolt is made of short-chipping brass MS 58.

The round dies MS from our production have a flatter rake angle and are also lapped. This makes them ideal for short-chipping materials. Below you will find more features of our MS series and also a short video of an application with a die holder in a bench. The bolt is made of short-chipping brass MS 58.

Advantages of the Round Dies MS

The round dies made of high-speed steel (HSS) provide the user with many other advantages:

The gun nosed chamfer causes a controlled chip removal in the cutting direction and at the same time there is a decrease in the cutting torque. This best possible chip removal optimises the surface quality of the thread produced, prevents the chip holes from becoming clogged and results in a considerable increase in tool life when using this cutting tool.

Furthermore, the round dies from our MS series are lapped. This means that with the help of an additional step during production, the surface roughness of the die is reduced. This results in a better, easier cut during use and the thread surface is significantly better.

The Round Dies MS die is suitable for machine use to a certain extent. This is because the lapped design also enables more precise work when used mechanically. Of course, other factors (such as cutting speed, sufficient lubricant, etc.) are also important in this context.

The gun nosed chamfer causes a controlled chip removal in the cutting direction and at the same time there is a decrease in the cutting torque. This best possible chip removal optimises the surface quality of the thread produced, prevents the chip holes from becoming clogged and results in a considerable increase in tool life when using this cutting tool.

Furthermore, the round dies from our MS series are lapped. This means that with the help of an additional step during production, the surface roughness of the die is reduced. This results in a better, easier cut during use and the thread surface is significantly better.

The Round Dies MS die is suitable for machine use to a certain extent. This is because the lapped design also enables more precise work when used mechanically. Of course, other factors (such as cutting speed, sufficient lubricant, etc.) are also important in this context.

Application range

The Round Dies MS can be used in an extraordinarily wide range of materials and can be optimally used in many other materials, especially short-chipping materials.

These include, for instance, brass and also bronze, as well as short-chipping materials up to 800 N/mm², in which the Round Dies MS can work with absolute precision and deliver optimum results.

Our MS series includes metric sizes up to M 30, many metric fine sizes up to M 24 and also pipe threads (G) up to 1 inch.

These include, for instance, brass and also bronze, as well as short-chipping materials up to 800 N/mm², in which the Round Dies MS can work with absolute precision and deliver optimum results.

Our MS series includes metric sizes up to M 30, many metric fine sizes up to M 24 and also pipe threads (G) up to 1 inch.