The technical support of VÖLKEL helps !!

At the end of last year, we at VÖLKEL received a complaint from a customer in Austria. The company Metzler informed us that their customer had used a machine nut tap Tr 12×3 LH (Art. 79116-L) from us and was complaining about it.

The customer, ERVO (a machining company, also from Austria), had machined just 20 components from the material AMPCO 21 (an aluminium bronze) with our nut tap and all three cutting edges of the tap had broken off. The thread to be created had initially been milled by the end user. Unfortunately, it was not deep enough, which is why the tap was used afterwards to re-cut the thread.

One of our application engineers then contacted the end user. In order to get an overview of the specific application, he asked the user to fill out an application questionnaire.

When the information was analysed, it quickly became clear where the problem in the application was located. The end user had used the tap by hand. This could not work under any circumstances, as the threaded part of a machine nut tap consists of up to 75 % lead and must therefore be guided by machine.

The customer, ERVO (a machining company, also from Austria), had machined just 20 components from the material AMPCO 21 (an aluminium bronze) with our nut tap and all three cutting edges of the tap had broken off. The thread to be created had initially been milled by the end user. Unfortunately, it was not deep enough, which is why the tap was used afterwards to re-cut the thread.

One of our application engineers then contacted the end user. In order to get an overview of the specific application, he asked the user to fill out an application questionnaire.

When the information was analysed, it quickly became clear where the problem in the application was located. The end user had used the tap by hand. This could not work under any circumstances, as the threaded part of a machine nut tap consists of up to 75 % lead and must therefore be guided by machine.

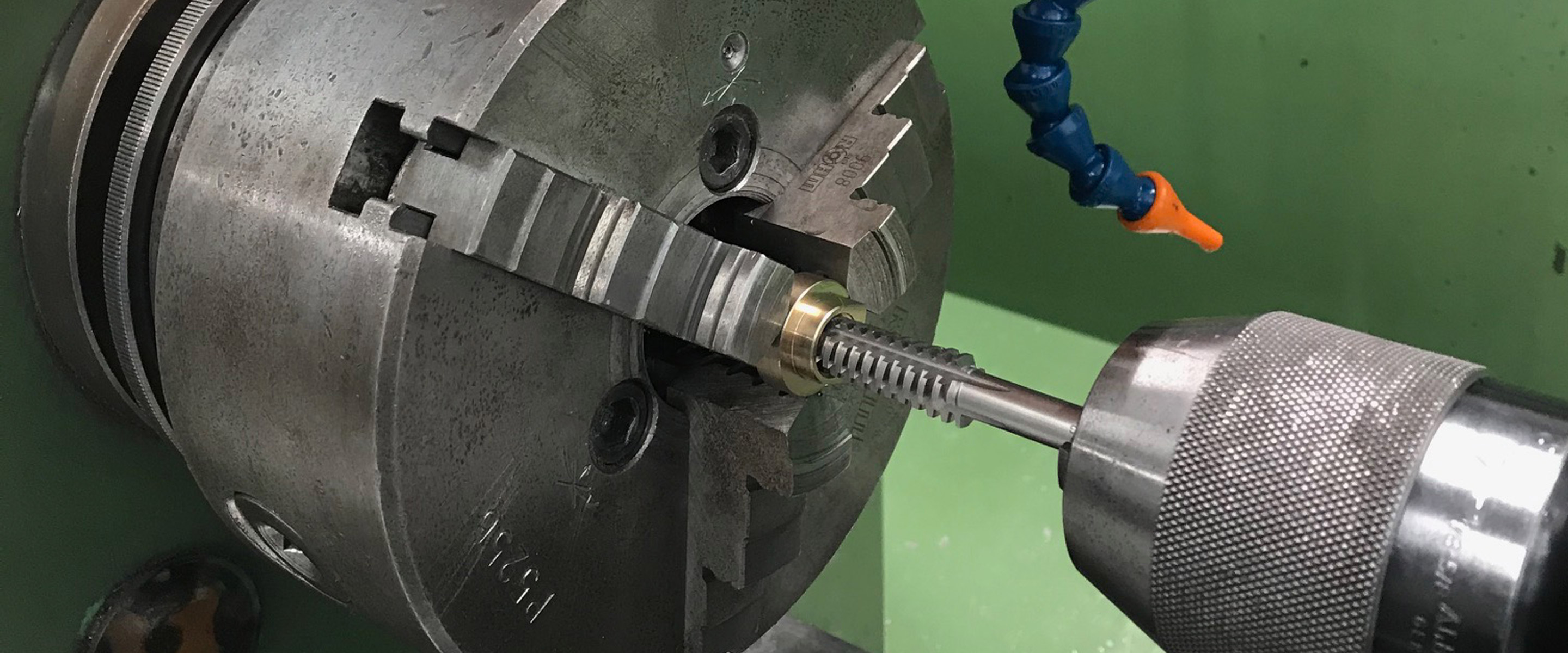

Our technician then contacted the end user again. He explained the situation to him and together they discussed the matter and looked for a solution. In ERVO’s training workshop there is a lathe on which the machine nut tap can be used. Our application engineer also gave the end user the correct machine parameters (cutting speed, etc.) and a recommendation for the right lubricant.

The result: With the help of VÖLKEL’s technical support, the end user was able to rework his threaded bushings without any problems and accurately to the required dimension. Everyone involved was completely satisfied with the outcome.

The result: With the help of VÖLKEL’s technical support, the end user was able to rework his threaded bushings without any problems and accurately to the required dimension. Everyone involved was completely satisfied with the outcome.