High-Octane Motor Sports – VÖLKEL in the Formula Student

High-Octane Motorsports e.V. is the Formula Student Team of the Friedrich-Alexander-University from Erlangen-Nürnberg (Germany). Formula Student is a competition in which a number of international student teams compete against each other in several categories.

The major challenge is the conception, design and manufacturing of an innovative and unique racing car. Formula Student supports our engineers and mechanics of tomorrow, because this international competition enhances the theory of a course of study with practical experience in the field of development and manufacturing.

The major challenge is the conception, design and manufacturing of an innovative and unique racing car. Formula Student supports our engineers and mechanics of tomorrow, because this international competition enhances the theory of a course of study with practical experience in the field of development and manufacturing.

In many aspects, lightweight construction plays an extremely important role. Therefore, aluminum alloys or fiber composites are often used for the individual components.

The prototypes that are used are frequently undergoing maintenance work, which puts a great amount of strain on the threads at the relevant locations. From time to time, the threads are also completely damaged due to the significantly faster abrasion and can no longer be used. In order to be able to keep using the advantageous lightweight components and not have to switch to heavy steel constructions, the idea was born to reinforce the affected threads with the V-COIL system from VÖLKEL and thus preserve the good performance of the vehicles.

The prototypes that are used are frequently undergoing maintenance work, which puts a great amount of strain on the threads at the relevant locations. From time to time, the threads are also completely damaged due to the significantly faster abrasion and can no longer be used. In order to be able to keep using the advantageous lightweight components and not have to switch to heavy steel constructions, the idea was born to reinforce the affected threads with the V-COIL system from VÖLKEL and thus preserve the good performance of the vehicles.

We at VÖLKEL were pleased to support the High Octane Motor Sports Team and provided the racing crew with various V-COIL rapid kits.

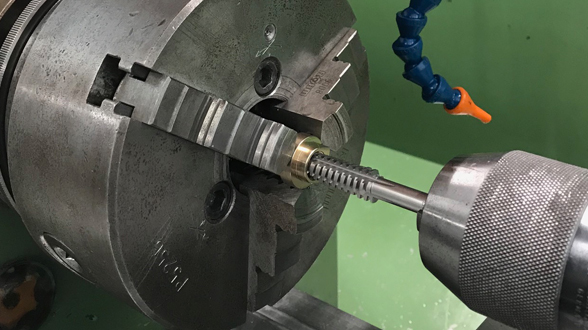

On the pictures you can see how the V-COIL system was used to repair two threads on the connection of the clutch’s slave cylinder. Therefore, the engine remained functional and the team was able to start with several engines into the crucial competition phase.

In addition, a worn thread in the lower part of the ignition cover was renewed. This made it possible to apply the surface pressure required for the seal and to provide a clean sealing of the engine. Both jobs were carried out without any problems and the mechanics are especially impressed by the flexible drive options of the V-COIL rapid system. In this case the assembly of the V-COIL thread inserts was realized with a ratchet and bit-nut and could be carried out easily, despite the difficult clamping situation.

On the pictures you can see how the V-COIL system was used to repair two threads on the connection of the clutch’s slave cylinder. Therefore, the engine remained functional and the team was able to start with several engines into the crucial competition phase.

In addition, a worn thread in the lower part of the ignition cover was renewed. This made it possible to apply the surface pressure required for the seal and to provide a clean sealing of the engine. Both jobs were carried out without any problems and the mechanics are especially impressed by the flexible drive options of the V-COIL rapid system. In this case the assembly of the V-COIL thread inserts was realized with a ratchet and bit-nut and could be carried out easily, despite the difficult clamping situation.