Round dies, left hand (set of 19 pcs.) incl. guides M 3 LH – M 12 LH

€118.00

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

Round dies, left hand (set of 19 pcs.) incl. guides M 3 LH – M 12 LH

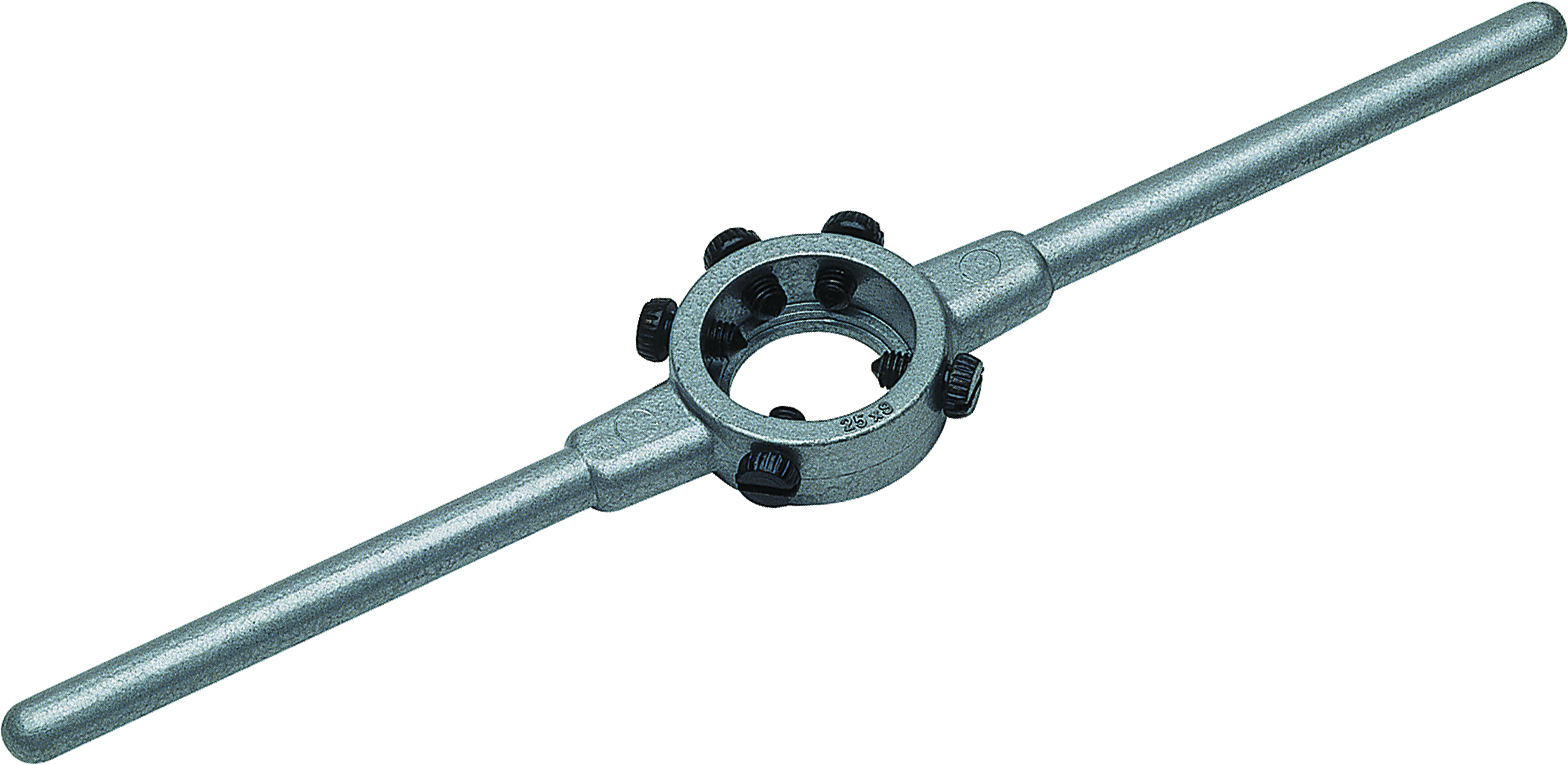

You use this accessory to hold or guide threading tools so the cutting edges start square and stable. It supports controlled handling in workshop and maintenance operations.

Metric ISO identifies ISO metric threads defined by the M designation and used across general engineering. Left hand means the thread advances when you rotate counterclockwise, which affects how you set up drive direction and torque control.

Application

- Hold, guide, or drive threading tools so the cutting edges start square to the workpiece axis.

- Use in workshop environments when alignment and repeatable torque control matter.

- Secure the tool firmly so it does not tilt under load during the first thread turns.

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

Note Verify the workpiece preparation before you start and stop if torque increases unexpectedly.

Benefits

- Improves alignment and reduces risk of cross-threading during thread start.

- Supports controlled torque input when you work by hand or with assisted drive.

- Speeds up tool changes and keeps the tool interface protected in regular use.

- Helps maintain a consistent thread axis in repair and workshop work.

- Requires a correct match to your tool size and interface stated in the product name.

- Not suitable for heavy industrial power tapping without a dedicated machine interface.

Step by step

- Select the accessory variant that matches the tool interface stated in the product name.

- Clean the clamping surfaces so the tool sits flat and does not tilt under load.

- Insert the tap or die fully and secure it with the provided clamping or locking feature.

- Align the assembly to the workpiece axis and support it so the first turns start square.

- Apply suitable cutting fluid to the cutting tool and start the operation with controlled torque.

- Re-adjust alignment if torque rises abruptly, then continue with steady feed.

- After use, remove the tool, clean all parts, and protect the clamping surfaces from corrosion.

Scope of supply

- 19 pieces Round dies, left hand (set of 19 pcs.) incl. guides M 3 LH – M 12 LH

Technical features

- Tool type: Thread cutting die

- Thread system: Metric ISO

- Thread direction: Left hand

Frequently asked questions (FAQ)

- How do you select the correct tool variant from the product name?

- Match the thread designation and standard stated in the product name to your drawing or the mating fastener. Confirm whether you need an internal or external thread tool and whether the thread is left hand or right hand.

- What does the thread designation in the product name mean?

- Metric ISO identifies ISO metric threads defined by the M designation and used across general engineering.

- Where can you find technical guidance for round dies?

- Technical information round dies as PDF

- How do you reduce the risk of cross-threading at the start?

- Prepare a clean chamfer and keep the tool axis aligned with the hole or rod axis. Start with controlled torque and stop if the tool tilts or binds.

- How do you verify the result after threading?

- Use the mating part or a suitable thread gauge to confirm smooth engagement and correct fit. Clean the thread first so chips do not mask the result.

- Where can you find more product and application information in a catalog?

- VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.

| Type of thread | metric ISO-thread DIN 13 |

|---|---|

| Standard | DIN Standard |

| Material | HSS-G |

| Size | Diameter M 3 - 12 |

| Packing | in metal case |

| EAN | 4022835495987 |

| Item number | 49598 |

Round dies, left hand (set of 19 pcs.) incl. guides M 3 LH – M 12 LH

You use this accessory to hold or guide threading tools so the cutting edges start square and stable. It supports controlled handling in workshop and maintenance operations.

Metric ISO identifies ISO metric threads defined by the M designation and used across general engineering. Left hand means the thread advances when you rotate counterclockwise, which affects how you set up drive direction and torque control.

Application

- Hold, guide, or drive threading tools so the cutting edges start square to the workpiece axis.

- Use in workshop environments when alignment and repeatable torque control matter.

- Secure the tool firmly so it does not tilt under load during the first thread turns.

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

Note Verify the workpiece preparation before you start and stop if torque increases unexpectedly.

Benefits

- Improves alignment and reduces risk of cross-threading during thread start.

- Supports controlled torque input when you work by hand or with assisted drive.

- Speeds up tool changes and keeps the tool interface protected in regular use.

- Helps maintain a consistent thread axis in repair and workshop work.

- Requires a correct match to your tool size and interface stated in the product name.

- Not suitable for heavy industrial power tapping without a dedicated machine interface.

Step by step

- Select the accessory variant that matches the tool interface stated in the product name.

- Clean the clamping surfaces so the tool sits flat and does not tilt under load.

- Insert the tap or die fully and secure it with the provided clamping or locking feature.

- Align the assembly to the workpiece axis and support it so the first turns start square.

- Apply suitable cutting fluid to the cutting tool and start the operation with controlled torque.

- Re-adjust alignment if torque rises abruptly, then continue with steady feed.

- After use, remove the tool, clean all parts, and protect the clamping surfaces from corrosion.

Scope of supply

- 19 pieces Round dies, left hand (set of 19 pcs.) incl. guides M 3 LH – M 12 LH

Technical features

- Tool type: Thread cutting die

- Thread system: Metric ISO

- Thread direction: Left hand

Frequently asked questions (FAQ)

- How do you select the correct tool variant from the product name?

- Match the thread designation and standard stated in the product name to your drawing or the mating fastener. Confirm whether you need an internal or external thread tool and whether the thread is left hand or right hand.

- What does the thread designation in the product name mean?

- Metric ISO identifies ISO metric threads defined by the M designation and used across general engineering.

- Where can you find technical guidance for round dies?

- Technical information round dies as PDF

- How do you reduce the risk of cross-threading at the start?

- Prepare a clean chamfer and keep the tool axis aligned with the hole or rod axis. Start with controlled torque and stop if the tool tilts or binds.

- How do you verify the result after threading?

- Use the mating part or a suitable thread gauge to confirm smooth engagement and correct fit. Clean the thread first so chips do not mask the result.

- Where can you find more product and application information in a catalog?

- VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.

Recommended products

Related products