How do you select the correct thread designation for this tool

Match the designation in the product name to the drawing, the mating part, and the required thread series, then align the tool choice with the hole type and manufacturing route.

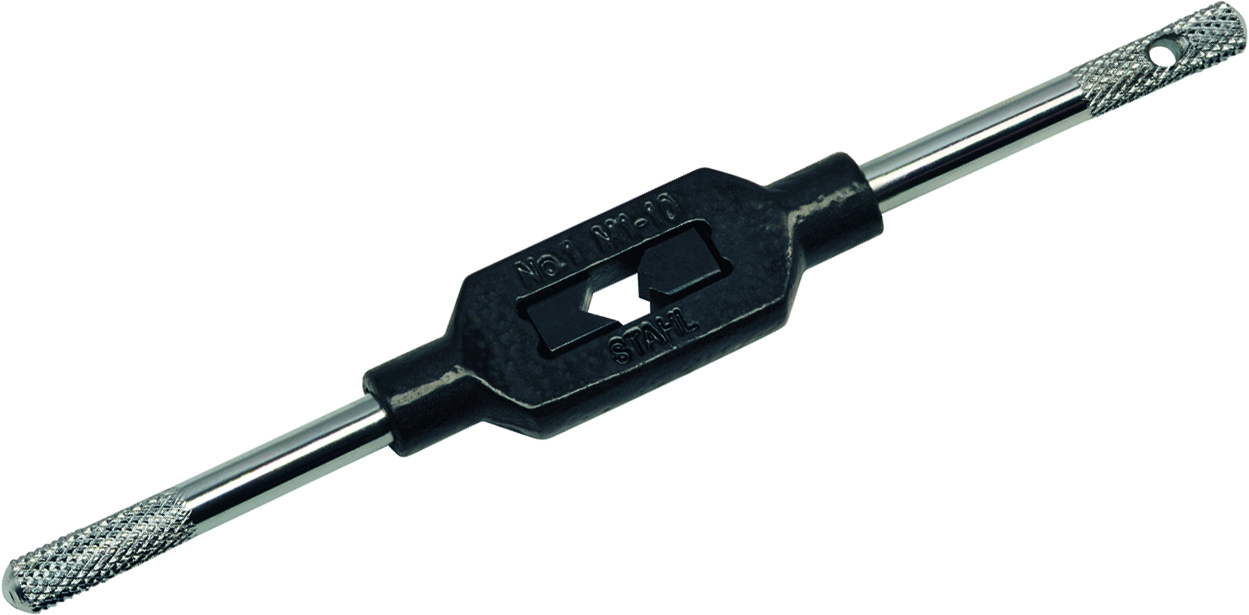

Which holder is typically used for manual tapping

A tap wrench that clamps the square shank is the typical choice, and you keep the tool axis aligned to the hole to reduce side load.

How do you reduce the risk of tap breakage

Keep alignment, use suitable lubrication, avoid side loading, and clear chips from the flutes so torque does not rise suddenly.

Which workpiece materials are typical for this threading tool

Thread cutting tools are commonly used in steels, cast iron, and many non ferrous alloys, but you should adapt lubricant choice and process control for hard, sticky, or abrasive materials.

How do you check thread quality after tapping

Use a suitable gauge or the intended mating part to confirm functional fit, and inspect the first threads for damage or misalignment.

Do you need lubrication and how do you manage chips

Use a cutting fluid suitable for the material to reduce friction, and clear chips from the flutes during the process to keep torque stable.

Where can you find additional technical information for selection and standards

For an overview of threading tools and related standards, refer to the VD 23 catalog as PDF.