What preparation is required before tapping?

Prepare the hole according to the thread standard for the nominal designation, and remove burrs at the entry. Clean the surface so chips and debris do not enter the flutes.

How do you reduce wear and improve thread surface quality?

Use a cutting fluid suited to the workpiece material and keep the tool aligned during entry. Clean chips from the cutting area and stop if torque rises unexpectedly.

How do you choose the correct variant?

Match the thread system and nominal size shown in the product name to the thread you need. Also consider the workpiece material and whether you need a hand guided or machine driven process.

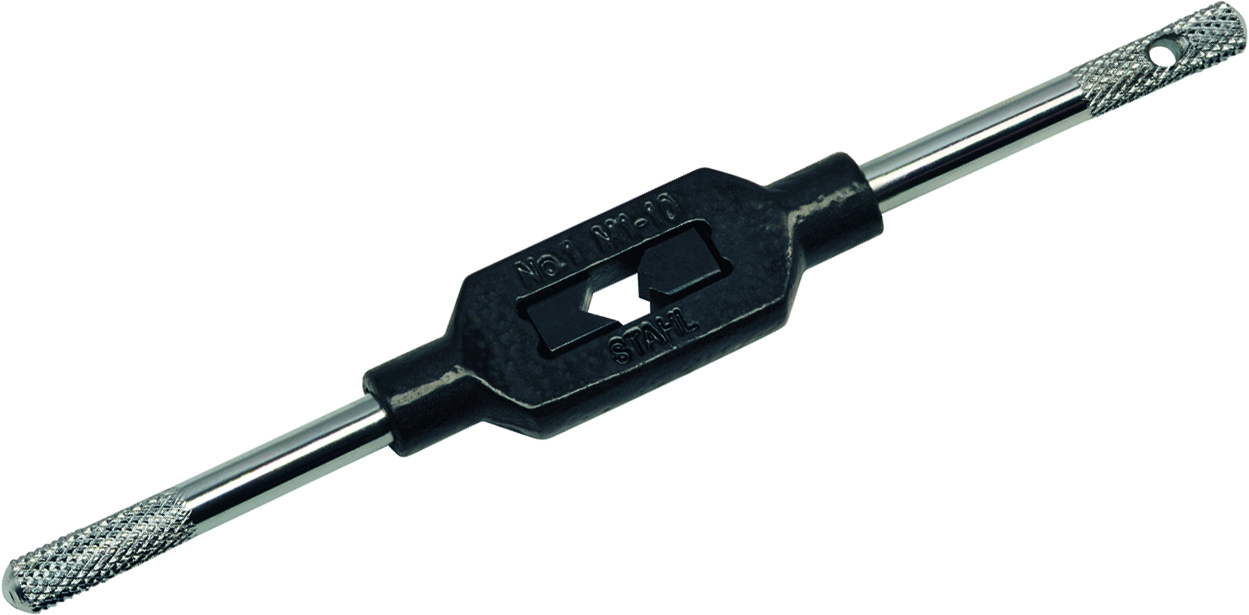

Which holder or drive method is appropriate?

For hand taps you typically use a tap wrench for guided manual torque. For machine taps you use a machine holder such as a tapping chuck or collet system that keeps the tool aligned.

How do you care for the tool after use?

Remove chips and coolant residue, then dry and lightly protect against corrosion if needed. Store the tool so cutting edges do not contact other tools.

How do you store the product to maintain accuracy and edge condition?

Store it dry and protected from impact, and keep protective caps or packaging in place if supplied. Avoid contact between functional surfaces and other tools.

Where can you find further selection tables and technical guidance in the catalog?

Use the catalog for additional information and selection support. VD 23 catalog as PDF