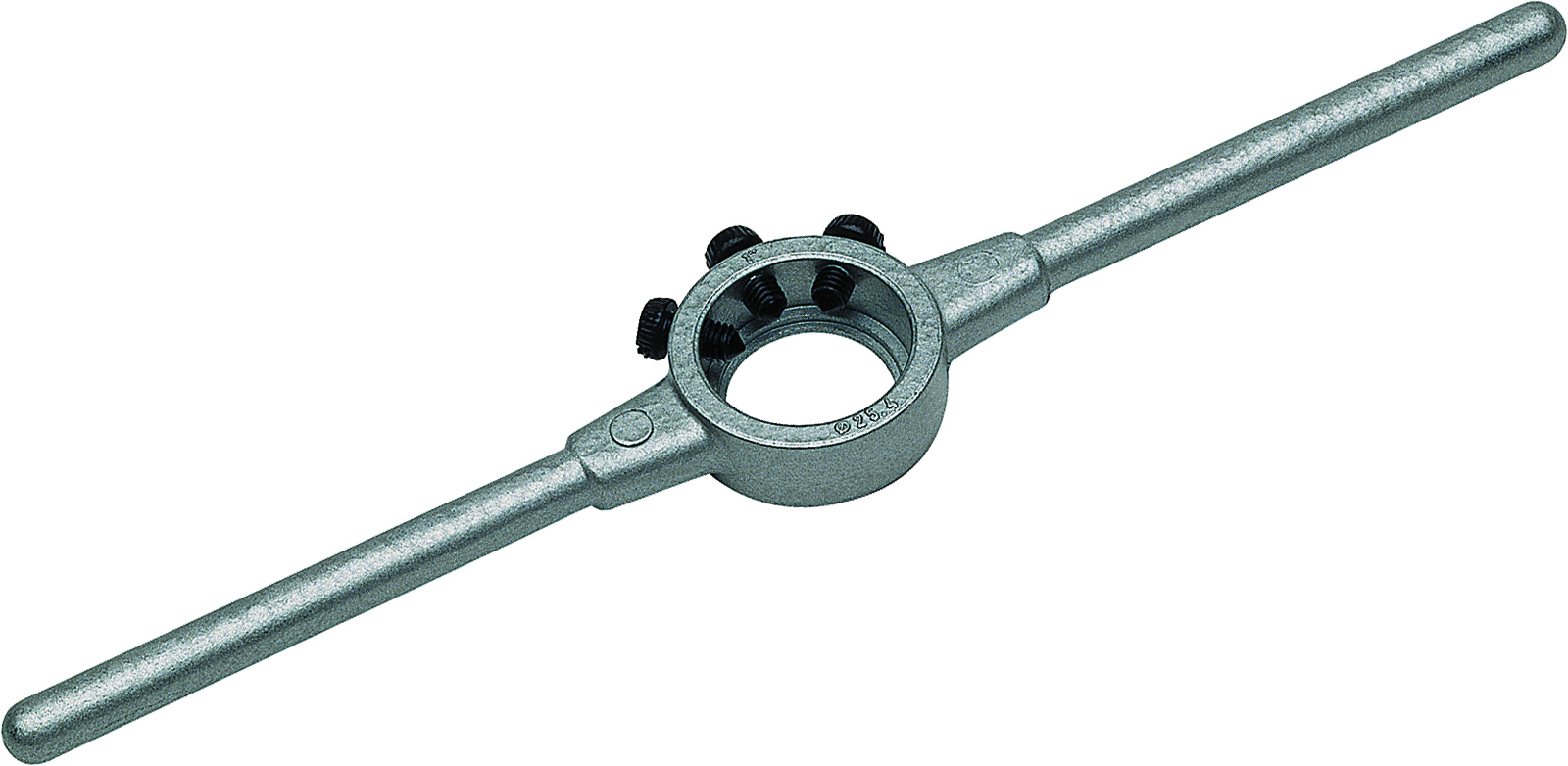

Die Stock steel 4'' | VÖLKEL

Die Stock steel 4

Die Stock steel 4 supports controlled thread cutting when you select it by thread system and apply it in a stable, guided setup. It fits typical shop workflows in machine building, service, and metal fabrication.

Selection is mainly driven by the thread designation and by keeping the process aligned and stable.

- Threading Tool use in repair and small batch work, including service workshops and mechanical engineering.

- Thread production on prepared holes or blanks where alignment is controlled by a holder, guide, or machine spindle.

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

- Use suitable lubrication and remove chips regularly so cutting edges do not pack up.

Note Clean threads and tools before use, apply suitable lubrication for cutting operations, and stop if resistance rises sharply.

- Direct selection by thread designation reduces setup mistakes.

- Suitable for workshop processes where alignment and controlled engagement are practical priorities.

- Supports consistent thread quality when you use steady feed and lubrication.

- Works well for maintenance tasks where parts must be reworked to the drawing requirement.

Drawbacks

- Not suitable for materials or hardness outside the typical range for the named tool material and execution.

- Not intended for high performance production without a validated process and rigid machine conditions.

- Inspect the blank and remove burrs so the die can start square to the axis.

- Mount the die in a suitable die holder and secure it so it cannot tilt under load.

- Align the holder to the workpiece axis and apply suitable cutting lubricant.

- Start the thread with steady rotation and maintain axial alignment without side force.

- Reverse briefly to clear chips from the cutting edges, then continue with steady feed.

- Continue until required engagement is reached, then back the die off fully.

- Clean the thread and the die, then protect the tool from corrosion before storage.

- 1 piece Die Stock steel 4

- Product type: Threading Tool

- How do you decide between a hand tap and a machine tap for this thread?

- You choose by the driving method and the stability of the setup. Hand taps support controlled manual work, while machine taps support guided or powered driving with stable alignment.

- What do you check before you start cutting the thread?

- Confirm the thread designation, the hole preparation, and the workpiece material. Keep alignment square to the axis and plan lubrication and chip evacuation.

- How do you reduce the risk of a tapered or oversize thread?

- Maintain alignment, avoid side load, and use steady feed. Clean chips from the cutting geometry and verify the first part against the specification.

- Where do you find the matching catalog for additional variants and reference data?

- Use the catalog for additional information and product family context: VD 23 catalog as PDF

- How do you choose the correct drill preparation without guessing values?

- Use a drill size chart that matches the thread system and the tool type. For inch based threads, confirm that the notation is interpreted correctly before drilling.

- When should you replace the tool instead of forcing it?

- Replace it if cutting torque rises abruptly, if the tool rubs without cutting, or if the thread surface becomes torn. Forcing a worn tool can damage the workpiece and the tool.

Do you need help selecting or using the product?

Use the contact form.