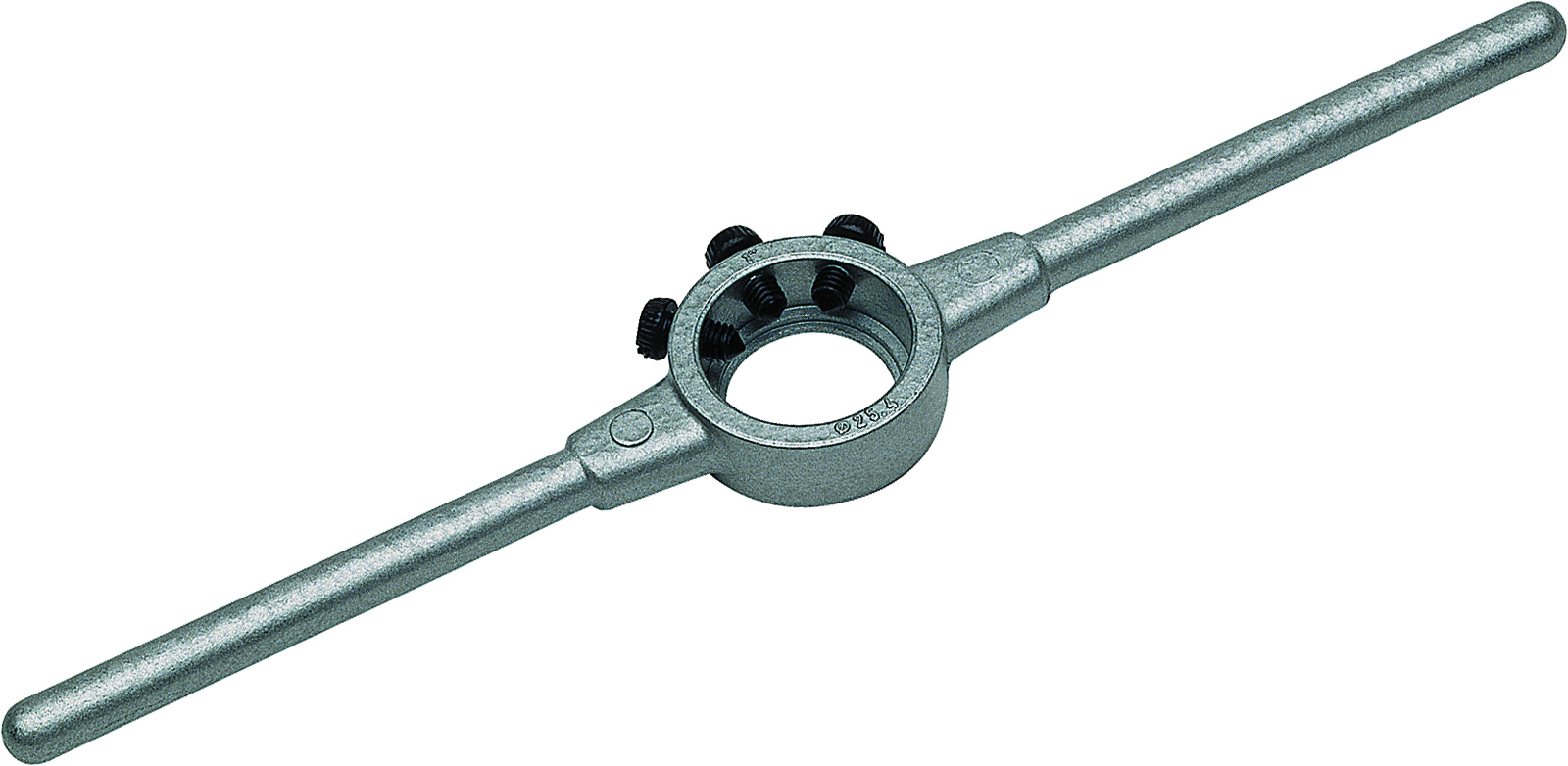

Die Stock Zinc die cast 1.1/2 | VÖLKEL

Die Stock Zinc die cast 1.1/2

This die holder is used for external thread cutting and for reworking damaged male threads in the designation Die Stock Zinc die cast 1.1/2. It is based on a relevant threading standard and is intended for controlled manual or guided use in maintenance and fabrication settings.

Before cutting you prepare the blank and thread start according to your process plan and then keep the tool guided during feed. If the workpiece material is very hard or abrasive, consider tool grade and cutting conditions before you start.

- Cut external threads on bolts, studs, and shafts during part manufacture and repair work

- Rework damaged external threads when a mating part no longer runs freely

- Use in maintenance, plant engineering, and metal fabrication where thread form and fit must match a drawing

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

Note Select the variant that matches the thread standard, hand direction, and tolerance requirements stated in your drawing.

- Supports controlled external thread cutting with a defined profile

- Round die format can be clamped in common die holders depending on execution

- Standard based geometry helps you align the result to the specified thread system

- Tool steel grade supports repeatable cutting performance in common workshop materials depending on execution

Drawbacks

- Limited performance in very hard, abrasive, or heat treated materials depending on tool grade and coating

- Not suitable for high volume production where cycle time and tool life must be maximized

- Confirm the interface and capacity in the product name and match it to the tool you want to hold

- Clean all contact surfaces so clamping faces sit flat and debris does not affect alignment

- Insert the tool fully into the holder interface and orient it according to the holder design

- Tighten the clamping element evenly until the tool is secure and cannot shift under load

- Align the holder to the work axis or guide feature before you start the operation

- Perform the process with steady control and stop if you feel abnormal resistance

- Release the clamp, remove the tool, and clean the holder after use

- Apply corrosion protection if you store the holder in a humid workshop environment

- Tool type: Die holder

- Thread designation: Die Stock Zinc die cast 1.1/2

- How do you choose the correct thread standard and designation?

- Match the thread system, pitch, and hand direction to the specification on your drawing and to the product name. If you work with inch based threads, also verify the designation and the intended fit before cutting.

- Which holder do you need for a round die?

- Use a suitable round die holder or guided die stock that clamps the die securely and keeps alignment. Holder features depend on execution, so check clamping method and guidance before use.

- What helps you avoid misalignment during the first turns?

- Start square to the work axis, apply suitable lubricant, and use a guide when available. If the die starts crooked, stop early and correct the setup to prevent damaged thread flanks.

- When should you replace or regrind the tool?

- Replace the die when cutting forces rise noticeably, the thread surface becomes rough, or the profile no longer meets your inspection method. Clean the tool first, since packed chips can mimic wear.

- How do you store the die after use?

- Remove chips, wipe off cutting fluid, and apply light corrosion protection if your storage is humid. Keep the cutting edges protected from contact with hard tools.

- Where can you find the full VÖLKEL catalog for selection support?

- Use the catalog for the complete range, execution variants, and reference tables. VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.