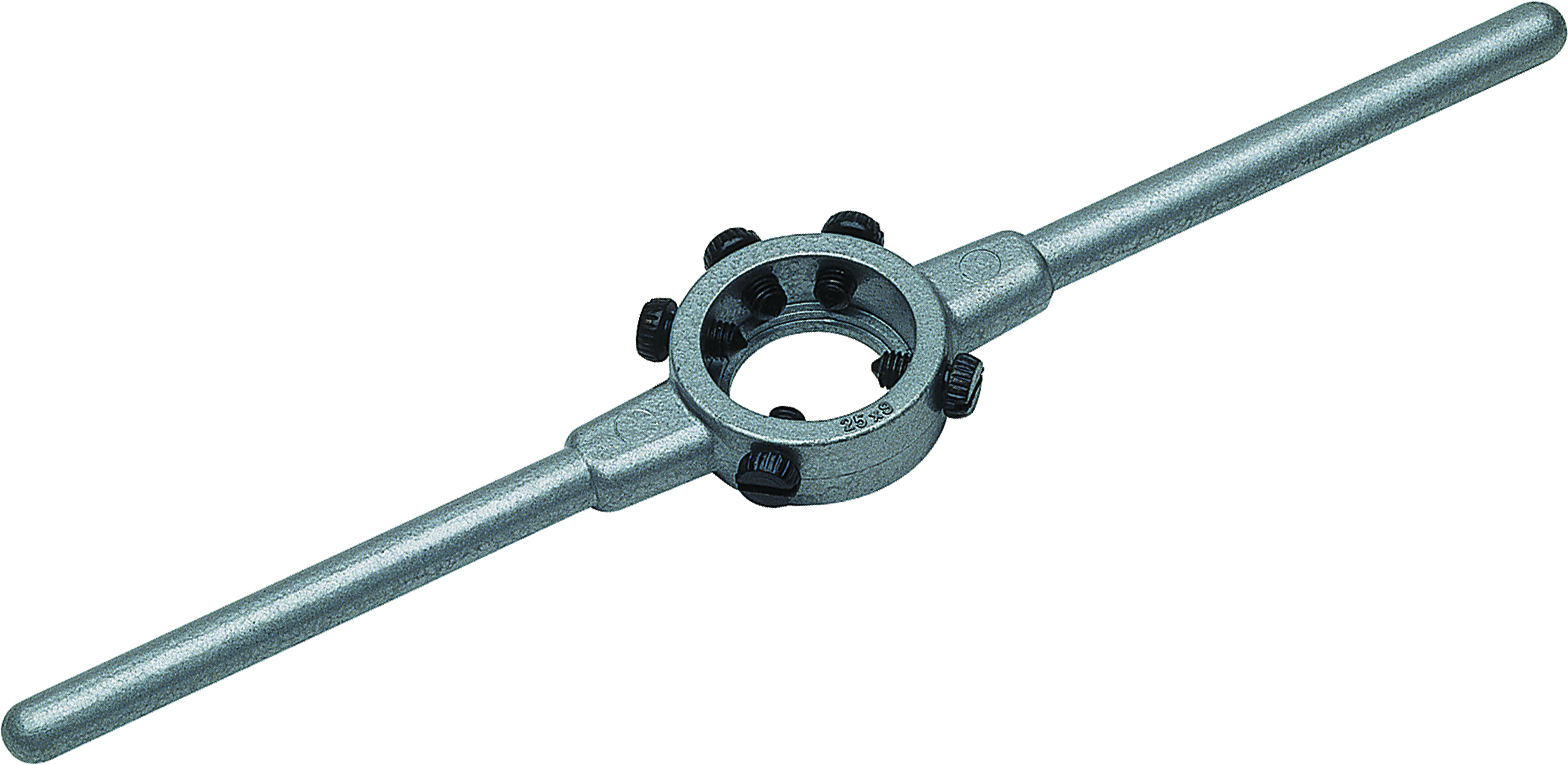

Die Stock Zinc die cast 45 x 14 mm | VÖLKEL

Die Stock Zinc die cast 45 x 14 mm

You use this threading tool to generate or renew a thread in workshop production and maintenance work.

A clean start and stable guidance help you achieve a thread that assembles smoothly and supports predictable clamp load.

- Clamp the threading tool securely and guide it with stable alignment to reduce side load on the cutting edges.

- Use the holder to support controlled starting, especially when you work close to shoulders or into restricted access points.

- Support rework and maintenance tasks where repeatable hand guidance improves thread quality.

Note Select the holder execution stated in the product name and verify interface fit before you apply cutting load.

- Supports stable alignment so you can start the tool more square to the workpiece.

- Improves handling in rework tasks where access or visibility is limited.

- Helps you apply steady torque transfer without sudden load peaks.

- Supports repeatable tool changes during maintenance routines.

- Reduces risk of surface damage when you guide the tool with controlled contact.

Drawbacks

- Compatibility depends on interface and tool shank design, so you must match execution to your tools.

- Not intended for high speed automated production where dedicated machine holders are required.

- Confirm that the holder interface and the selected tool match each other and are clean.

- Clamp the tool evenly and verify that it sits straight without tilt.

- Align the holder to the hole axis or shaft axis before contact with the workpiece.

- Apply a suitable cutting lubricant to the tool and the work area.

- Guide the tool with steady torque while you maintain alignment throughout the cut.

- Release the tool, remove chips from the clamping area, and clean the holder surfaces.

- Protect the holder from corrosion and store it so the guiding surfaces stay undamaged.

- 1 piece die stock, execution as stated in the product name

- Tool type: Die stock

- Tool material: Zinc die cast

- Thread system: Thread system as stated in product name

- Execution: Depending on variant

- How do you confirm that the holder fits the selected tool?

- Check the interface type and clamping range stated for the holder and the tool, then verify that the tool sits straight and clamps without play.

- What should you focus on during setup?

- Focus on alignment to the hole axis or shaft axis, even clamping, and clean contact surfaces so guidance stays stable under load.

- What causes a rough thread surface after cutting?

- Common causes include misalignment, unsuitable lubricant, tool wear, or chips trapped in the flutes, so focus on straight guidance and clean working conditions.

- How do you extend tool life in routine use?

- Use a suitable lubricant, avoid side load, keep cutting edges protected from impact, and replace the tool when cutting forces or thread quality change.

- How do you confirm thread quality without measuring equipment?

- You can check assembly feel with a matching fastener and look for smooth engagement, then use a gauge if your process requires documented conformity.

- Where do you find the complete catalog context for this product class?

- For additional product and system information, use the catalog. VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.