Hand Tap set of 3 pieces DIN 352 HSS-G - M 15 x 2.0

€26.40

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

VÖLKEL Hand Tap Set of 3 pieces DIN 352 HSS-G - M 15 x 2.0

The VÖLKEL 3-piece Hand Tap Set is the ideal tool for the manual production of internal threads. This set, made of high-quality HSS-G (High-Speed Steel Ground), is perfect for general use in well-machinable materials and allows for the precise cutting of threads in through and blind holes.

What is a Hand Tap Set and What is it Used For?

A hand tap set typically consists of three sequential tools: a taper tap, a plug tap, and a bottoming tap. These are used step by step to cut an internal thread into a pre-drilled hole. The three-stage process allows for gradual material removal, ensuring high precision and a long tool life.

This set is intended for manual use with a tap wrench and is excellent for use in unalloyed and low-alloy steels up to a strength of 900 N/mm². It is suitable for both through holes and blind holes.

Explanation of the Markings

- DIN 352: A German industrial standard that specifies the dimensions and specifications of hand taps. It guarantees that the set complies with the technical requirements for hand tools.

- DIN 13: The standard for metric ISO threads, which defines the thread profile (in this case M 15 x 2.0). M 15 stands for the nominal diameter of 15 mm, and 2.0 is the thread pitch in millimeters.

- HSS-G: Stands for "High-Speed Steel Ground". This means the tap is made from high-performance high-speed steel and is additionally ground. The ground finish (G) ensures higher precision, a better surface quality, and a longer service life compared to a rolled finish.

- Tolerance ISO 2 / 6H: This refers to the thread tolerance class. ISO 2 / 6H is a standard tolerance for metric threads that ensures a medium fit. H stands for the basic deviation of the nut, and tolerance class 6 is the most commonly used for general purposes.

Blind Holes vs. Through Holes

Through holes are bores that go completely through a workpiece. When cutting threads in these holes, chips can fall out freely at the bottom.

Blind holes, on the other hand, are bores that do not go all the way through the workpiece. The thread ends at a certain point. Here, it is important to ensure that the chips do not jam the tool, which is why a tap set with different leads (taper, plug, bottoming) is ideal for cleanly cutting the thread and guiding the chips upwards.

Step-by-Step Instructions for Use

Follow these steps to cut a precise internal thread:

- Preparation: Drill a core hole with the appropriate diameter (typically 13.0 mm for M15x2.0). The hole should be clean and deburred.

- Taper Tap: Insert the taper tap (marked with one ring on the shank) vertically into the tap wrench and begin cutting the thread with light, even pressure. Turn the tap clockwise. Use cutting oil throughout the process.

- Plug Tap: Once the taper tap has pre-cut the thread, switch to the plug tap (with two rings) and repeat the process.

- Bottoming Tap: Finish the process with the bottoming tap (without a ring) to create the final, precise thread.

Frequently Asked Questions (FAQ)

1. Why do I need a 3-piece set?

A 3-piece set allows for the progressive cutting of the thread. Each tap removes only a small amount of material, which reduces the required force, increases accuracy, and extends the life of the tools.

2. What is the difference between HSS and HSS-G?

HSS-G (Ground) is a higher-quality version of HSS (Rolled). The ground surface is more precise and smoother, leading to cleaner thread cuts and better performance.

3. Can I use this set for stainless steel?

This set is designed for well-machinable steels up to 900 N/mm². For stainless steel or other difficult-to-machine materials, special taps with a suitable alloy and coating are required.

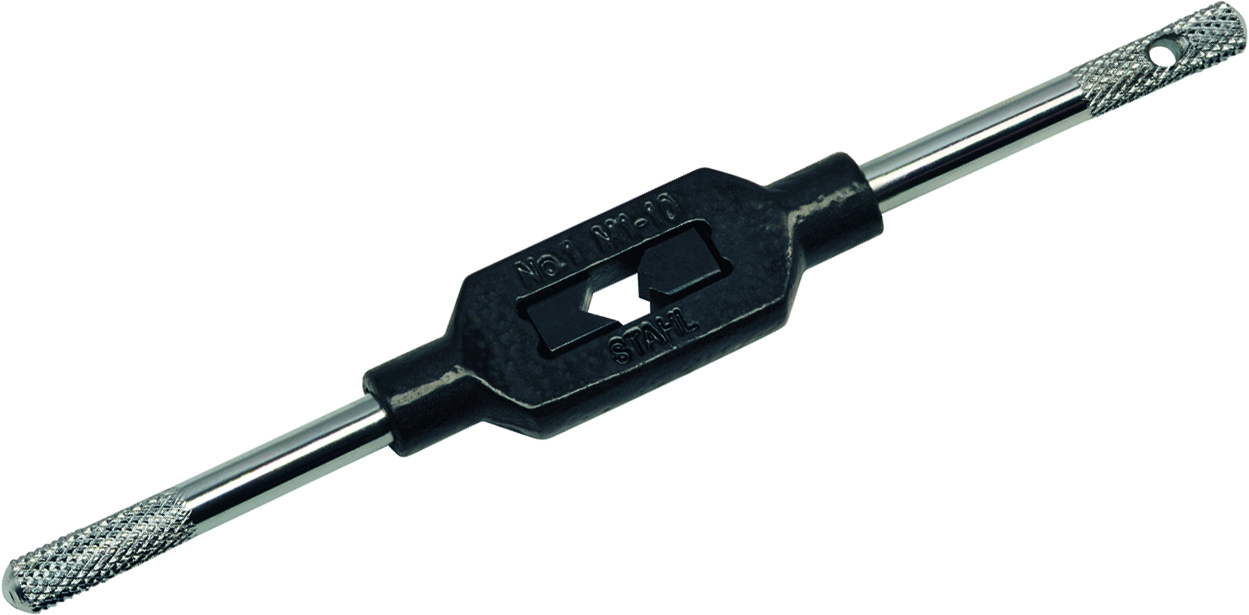

4. What tap wrench do I need for this set?

You need a tap wrench that can accommodate the 9 mm square drive. VÖLKEL offers suitable tap wrenches.

5. What does the tolerance 6H mean?

Tolerance class 6H is a standard tolerance for metric ISO threads. It ensures a medium fit that is sufficient for most screw connections.

Learn More About VÖLKEL Hand Taps Now!

Do you have questions about our products or would you like to learn more about the application of our hand taps? Our team is always at your disposal. Contact us today!

| Type of thread | metric ISO-thread |

|---|---|

| Standard | DIN 352 |

| Material | HSS-G |

| Tolerance | ISO2 (6H) |

| Size | M 15 x 2.0 |

| Overall length (L1) | 80 mm |

| Thread length (L2) | 32 mm |

| Core hole diameter (D1) | 13.0 mm |

| Shank diameter (D2) | 12.0 mm |

| Drive connector | 9.0 mm |

| EAN | 4022835273561 |

| Item number | 27356 |

| Type of flute | straight fluted |

| Application | for through and blind holes |

| Thread standard | DIN 13 |

VÖLKEL Hand Tap Set of 3 pieces DIN 352 HSS-G - M 15 x 2.0

The VÖLKEL 3-piece Hand Tap Set is the ideal tool for the manual production of internal threads. This set, made of high-quality HSS-G (High-Speed Steel Ground), is perfect for general use in well-machinable materials and allows for the precise cutting of threads in through and blind holes.

What is a Hand Tap Set and What is it Used For?

A hand tap set typically consists of three sequential tools: a taper tap, a plug tap, and a bottoming tap. These are used step by step to cut an internal thread into a pre-drilled hole. The three-stage process allows for gradual material removal, ensuring high precision and a long tool life.

This set is intended for manual use with a tap wrench and is excellent for use in unalloyed and low-alloy steels up to a strength of 900 N/mm². It is suitable for both through holes and blind holes.

Explanation of the Markings

- DIN 352: A German industrial standard that specifies the dimensions and specifications of hand taps. It guarantees that the set complies with the technical requirements for hand tools.

- DIN 13: The standard for metric ISO threads, which defines the thread profile (in this case M 15 x 2.0). M 15 stands for the nominal diameter of 15 mm, and 2.0 is the thread pitch in millimeters.

- HSS-G: Stands for "High-Speed Steel Ground". This means the tap is made from high-performance high-speed steel and is additionally ground. The ground finish (G) ensures higher precision, a better surface quality, and a longer service life compared to a rolled finish.

- Tolerance ISO 2 / 6H: This refers to the thread tolerance class. ISO 2 / 6H is a standard tolerance for metric threads that ensures a medium fit. H stands for the basic deviation of the nut, and tolerance class 6 is the most commonly used for general purposes.

Blind Holes vs. Through Holes

Through holes are bores that go completely through a workpiece. When cutting threads in these holes, chips can fall out freely at the bottom.

Blind holes, on the other hand, are bores that do not go all the way through the workpiece. The thread ends at a certain point. Here, it is important to ensure that the chips do not jam the tool, which is why a tap set with different leads (taper, plug, bottoming) is ideal for cleanly cutting the thread and guiding the chips upwards.

Step-by-Step Instructions for Use

Follow these steps to cut a precise internal thread:

- Preparation: Drill a core hole with the appropriate diameter (typically 13.0 mm for M15x2.0). The hole should be clean and deburred.

- Taper Tap: Insert the taper tap (marked with one ring on the shank) vertically into the tap wrench and begin cutting the thread with light, even pressure. Turn the tap clockwise. Use cutting oil throughout the process.

- Plug Tap: Once the taper tap has pre-cut the thread, switch to the plug tap (with two rings) and repeat the process.

- Bottoming Tap: Finish the process with the bottoming tap (without a ring) to create the final, precise thread.

Frequently Asked Questions (FAQ)

1. Why do I need a 3-piece set?

A 3-piece set allows for the progressive cutting of the thread. Each tap removes only a small amount of material, which reduces the required force, increases accuracy, and extends the life of the tools.

2. What is the difference between HSS and HSS-G?

HSS-G (Ground) is a higher-quality version of HSS (Rolled). The ground surface is more precise and smoother, leading to cleaner thread cuts and better performance.

3. Can I use this set for stainless steel?

This set is designed for well-machinable steels up to 900 N/mm². For stainless steel or other difficult-to-machine materials, special taps with a suitable alloy and coating are required.

4. What tap wrench do I need for this set?

You need a tap wrench that can accommodate the 9 mm square drive. VÖLKEL offers suitable tap wrenches.

5. What does the tolerance 6H mean?

Tolerance class 6H is a standard tolerance for metric ISO threads. It ensures a medium fit that is sufficient for most screw connections.

Learn More About VÖLKEL Hand Taps Now!

Do you have questions about our products or would you like to learn more about the application of our hand taps? Our team is always at your disposal. Contact us today!