Hand Tap set of 3 pieces ISO 529 HSS-G left hand thread - BSW 1/4 x 20 LH

€23.40

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

VÖLKEL Hand Tap set of 3 pieces ISO 529 HSS-G left hand thread - BSW 1/4 x 20 LH

The VÖLKEL Hand Tap set of 3 pieces ISO 529 HSS-G left hand thread - BSW 1/4 x 20 LH is a complete set for manually cutting internal threads. The set, consisting of a taper tap, plug tap, and bottoming tap, allows for the gradual and precise creation of Whitworth pipe threads in easy-to-machine materials.

Explanation of Technical Terms

Hand Tap set of 3 pieces: This set consists of three coordinated tools:

- Taper Tap (Chamfer A): The first tap in the set. It roughly pre-cuts the initial threads and ensures easy centering.

- Plug Tap (Chamfer C): The second tap. It deepens the thread and continues to form it.

- Bottoming Tap (Chamfer D): The third and final tap. It brings the thread to its final depth and correct profile to ensure the required fit.

BSW (British Standard Whitworth): This is a British thread standard (BS 84), considered one of the first standardized thread systems. It has a thread flank angle of 55°. The nominal size 1/4 x 20 indicates the outer diameter (1/4 inch) and the number of threads per inch (20).

Left-hand thread (LH): Unlike standard right-hand threads, which are tightened by turning clockwise, a left-hand thread is tightened by turning counter-clockwise. They are used to prevent a connection from loosening due to clockwise rotation or vibrations.

ISO 529: An international standard that specifies the basic dimensions and requirements for hand taps. It ensures the compatibility and quality of the tool.

Step-by-Step Instructions for Use

Follow these steps for the correct cutting of an internal thread:

- Preparation: Ensure the workpiece is securely clamped. Drill a core hole with the correct diameter for the BSW 1/4 x 20 thread.

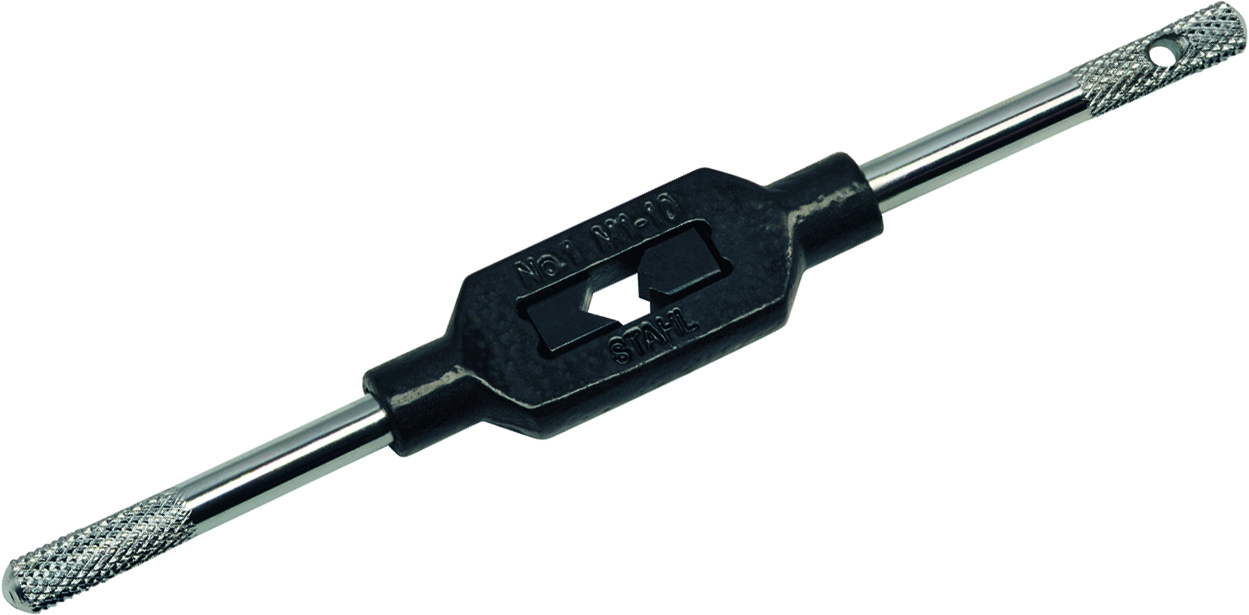

- Using the Taper Tap: Clamp the taper tap into a tap wrench. Place the tap vertically in the bore and turn slowly and evenly counter-clockwise, as it is a left-hand thread. Cut a few turns to start the thread.

- Using the Plug Tap: Replace the taper tap with the plug tap. Continue the same process to increase the thread depth.

- Using the Bottoming Tap: Now insert the bottoming tap. Cut the thread to the full depth and correct profile. Pay attention to a clean and straight guide.

- Cleaning: Carefully clean the finished thread of all chips.

- Inspection: Check the thread with a suitable thread gauge.

Frequently Asked Questions (FAQ)

1. What is the advantage of a 3-piece set over a single tap?

A 3-piece set allows for a gradual and precise cutting process, which reduces the load on the tool and improves thread quality. The different chamfers facilitate the start and ensure a clean, complete thread profile.

2. Why should I use a left-hand thread?

Left-hand threads are used when the connection might loosen due to clockwise rotation or vibrations. Examples include wheel nuts on the left side of a vehicle or certain spindles in machines that rotate counter-clockwise.

3. Can I use this set for stainless steels?

The HSS-G steel of the tap is suitable for materials with a strength of up to 900 N/mm². For high-alloy or stainless steels, we recommend taps made of HSSE or VHM (solid carbide), which are specially designed for these materials.

4. What is the difference between through holes and blind holes?

A through hole goes completely through the workpiece, while a blind hole has a specific depth. This hand tap set is suitable for both through and blind holes.

5. Can I use this set in a machine?

No, this set is specifically designed for manual use with a tap wrench. For machine applications, you should use a machine tap.

Learn more about VÖLKEL Threading Tools!

Do you have questions about our products or would you like to learn more about the application of our threading tools? Our team is at your disposal at any time. Contact us today!

| Type of thread | Whitworth-Thread |

|---|---|

| Standard | ISO 529 |

| Material | HSS-G |

| Tolerance | medium |

| Size | BSW 1/4 x 20 LH |

| Overall length (L1) | 66 mm |

| Thread length (L2) | 19 mm |

| Core hole diameter (D1) | 5.1 mm |

| Shank diameter (D2) | 6.3 mm |

| Drive connector | 5.0 mm |

| EAN | 4022835843108 |

| Item number | 84310 |

| Type of flute | straight fluted |

| Application | for through and blind holes |

| Thread standard | BS 84 |

VÖLKEL Hand Tap set of 3 pieces ISO 529 HSS-G left hand thread - BSW 1/4 x 20 LH

The VÖLKEL Hand Tap set of 3 pieces ISO 529 HSS-G left hand thread - BSW 1/4 x 20 LH is a complete set for manually cutting internal threads. The set, consisting of a taper tap, plug tap, and bottoming tap, allows for the gradual and precise creation of Whitworth pipe threads in easy-to-machine materials.

Explanation of Technical Terms

Hand Tap set of 3 pieces: This set consists of three coordinated tools:

- Taper Tap (Chamfer A): The first tap in the set. It roughly pre-cuts the initial threads and ensures easy centering.

- Plug Tap (Chamfer C): The second tap. It deepens the thread and continues to form it.

- Bottoming Tap (Chamfer D): The third and final tap. It brings the thread to its final depth and correct profile to ensure the required fit.

BSW (British Standard Whitworth): This is a British thread standard (BS 84), considered one of the first standardized thread systems. It has a thread flank angle of 55°. The nominal size 1/4 x 20 indicates the outer diameter (1/4 inch) and the number of threads per inch (20).

Left-hand thread (LH): Unlike standard right-hand threads, which are tightened by turning clockwise, a left-hand thread is tightened by turning counter-clockwise. They are used to prevent a connection from loosening due to clockwise rotation or vibrations.

ISO 529: An international standard that specifies the basic dimensions and requirements for hand taps. It ensures the compatibility and quality of the tool.

Step-by-Step Instructions for Use

Follow these steps for the correct cutting of an internal thread:

- Preparation: Ensure the workpiece is securely clamped. Drill a core hole with the correct diameter for the BSW 1/4 x 20 thread.

- Using the Taper Tap: Clamp the taper tap into a tap wrench. Place the tap vertically in the bore and turn slowly and evenly counter-clockwise, as it is a left-hand thread. Cut a few turns to start the thread.

- Using the Plug Tap: Replace the taper tap with the plug tap. Continue the same process to increase the thread depth.

- Using the Bottoming Tap: Now insert the bottoming tap. Cut the thread to the full depth and correct profile. Pay attention to a clean and straight guide.

- Cleaning: Carefully clean the finished thread of all chips.

- Inspection: Check the thread with a suitable thread gauge.

Frequently Asked Questions (FAQ)

1. What is the advantage of a 3-piece set over a single tap?

A 3-piece set allows for a gradual and precise cutting process, which reduces the load on the tool and improves thread quality. The different chamfers facilitate the start and ensure a clean, complete thread profile.

2. Why should I use a left-hand thread?

Left-hand threads are used when the connection might loosen due to clockwise rotation or vibrations. Examples include wheel nuts on the left side of a vehicle or certain spindles in machines that rotate counter-clockwise.

3. Can I use this set for stainless steels?

The HSS-G steel of the tap is suitable for materials with a strength of up to 900 N/mm². For high-alloy or stainless steels, we recommend taps made of HSSE or VHM (solid carbide), which are specially designed for these materials.

4. What is the difference between through holes and blind holes?

A through hole goes completely through the workpiece, while a blind hole has a specific depth. This hand tap set is suitable for both through and blind holes.

5. Can I use this set in a machine?

No, this set is specifically designed for manual use with a tap wrench. For machine applications, you should use a machine tap.

Learn more about VÖLKEL Threading Tools!

Do you have questions about our products or would you like to learn more about the application of our threading tools? Our team is at your disposal at any time. Contact us today!