VÖLKEL Hand Taps and Round Dies (Set of 22 pcs.) BSF 1/4 – 1/2

The VÖLKEL Hand Taps and Round Dies 22-piece Set is your specialist for precise cutting and re-cutting of BSF threads. This high-quality threading tool set covers the common dimensions from BSF 1/4" to BSF 1/2" and is ideal for vintage car restoration, mechanical engineering, or any application requiring the British Standard Fine thread. It is an indispensable tap and die set for anyone working with this specific thread type and valuing precise results.

Why the VÖLKEL BSF 22-pc. Set is indispensable

The VÖLKEL threading set stands out for its first-class quality and specialization in BSF threads. It is a must-have for anyone working with this special thread type and valuing precise results.

Ideal Application and Material Compatibility:

The HSS-G hand taps and HSS round dies included in the set are robust and versatile for:

- Materials with good machinability

- Unalloyed and low-alloy steels

- Through holes and blind holes

No matter whether you are cutting threads in old machines, vehicles, or special constructions, this set delivers the required precision.

High-Quality Components for Durability and Efficiency:

- HSS-G Hand Taps 2-pc. Set

The ground hand taps made of HSS according to DIN offer excellent cutting performance. Each size consists of a taper tap and a plug tap: - HSS Round Dies

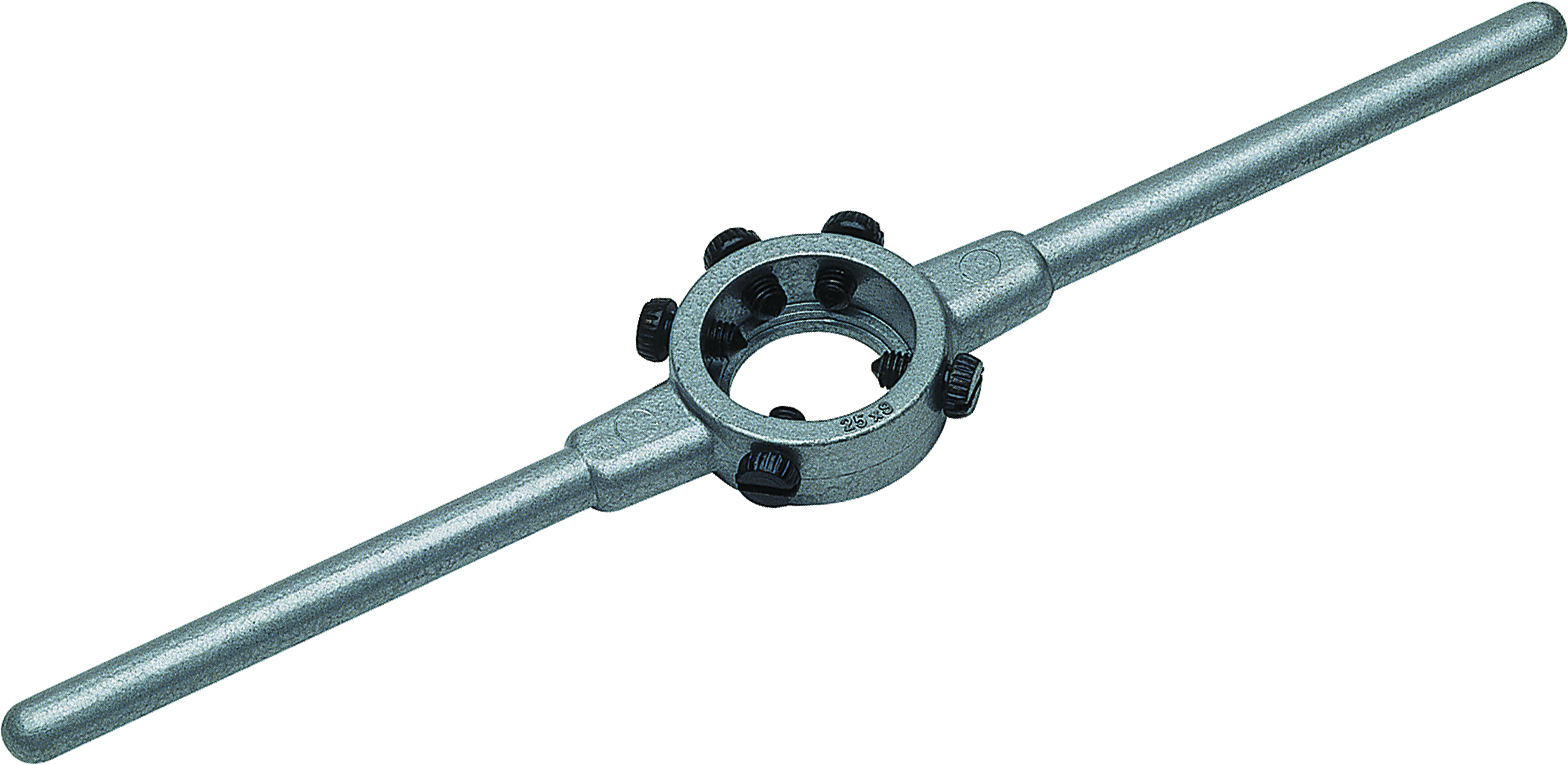

For precise cutting of external threads – dimensionally accurate and wear-resistant: - Adjustable Tap Wrenches (Die Cast Zinc)

- Die Stocks (Die Cast Zinc)

- Ratchet Tap Wrench

- Size 1 (10001)

Flexibility and Reorderability:

All threading tools and accessories in this set can also be ordered separately – for maximum flexibility for additions or replacements.

Step-by-Step Instructions

Instructions for Cutting Internal Threads

Here's how to cut a precise **internal thread** with the hand tap set:

- Preparation: Select the appropriate tap and drill the core hole to the correct diameter. Apply generous amounts of cutting oil to the tap and into the hole to reduce friction and protect the tools.

- Tool Clamping: Clamp the taper tap (with the longer chamfer length) into the adjustable tap wrench.

- Pre-tapping: Insert the tap vertically into the drilled hole. Start turning the tool clockwise slowly and with even pressure.

- Finishing: Replace the taper tap with the plug tap (with the shorter chamfer length) and cut the thread to the desired depth.

- Cleaning: Carefully remove the tap and clean the finished **internal thread** and tools from chips and oil.

Instructions for Cutting External Threads

Here's how you can cut a precise **external thread**:

- Preparation: Select the appropriate round die and the bolt with the correct outer diameter. Apply generous amounts of cutting oil to the die and the bolt.

- Tool Clamping: Clamp the round die into the appropriate **threading tool holder** (die stock).

- Cutting the Thread: Begin turning the round die slowly and evenly clockwise with light pressure. Ensure vertical guidance.

- Completion: Cut the **external thread** to the desired length. Perform the cut in a continuous motion to achieve a clean result.

- Cleaning: Remove the **die stock** and clean the finished thread and the round die from chips and oil.

Frequently Asked Questions (FAQ)

1. What is the difference between a hand tap set and a machine tap?

A hand tap set, as included in this **tap and die set**, is typically used by hand with a tap wrench and consists of multiple parts to enable precise **internal thread cutting**. Machine taps are optimized for use in drilling machines or tapping machines and often cut the thread in a single operation.

2. What is the function of the taper tap and the plug tap?

The taper tap has a shorter chamfer length and initiates the threading process by preparing the material. The plug tap, with a longer chamfer length, completes the thread and ensures final precision and dimensional accuracy.

3. Can I cut other threads with this set?

No, this set is specifically designed for BSF threads. For cutting metric ISO threads or other thread types, you will need the corresponding **BSF threading tool set** or a separate set.

4. What is the advantage of HSS-G material?

HSS-G stands for High-Speed Steel with ground cutting surfaces. This leads to higher precision, a better surface finish of the thread, and a longer tool life, which is particularly important when **cutting external threads**.

5. What are BSF threads and what are they used for?

BSF stands for "British Standard Fine" and is a fine thread standard primarily used in Great Britain in older machines, vehicles, and bicycles. It is characterized by a larger core diameter and higher strength compared to metric threads.

Order now and rely on quality

Secure your VÖLKEL Hand Taps and Round Dies 22-piece Set BSF 1/4 – 1/2 now and master every challenge in the field of BSF threads with precision and reliability! For more information, visit our website or contact us via our contact form.

| Type of thread | British-Standard-Fine-thread BS 84 |

|---|---|

| Standard | DIN Standard |

| Material | HSS-G |

| Size | Diameter BSF 1/4 - 1/2 |

| Packing | in metal case |

| EAN | 4022835480419 |

| Item number | 48041 |

VÖLKEL Hand Taps and Round Dies (Set of 22 pcs.) BSF 1/4 – 1/2

The VÖLKEL Hand Taps and Round Dies 22-piece Set is your specialist for precise cutting and re-cutting of BSF threads. This high-quality threading tool set covers the common dimensions from BSF 1/4" to BSF 1/2" and is ideal for vintage car restoration, mechanical engineering, or any application requiring the British Standard Fine thread. It is an indispensable tap and die set for anyone working with this specific thread type and valuing precise results.

Why the VÖLKEL BSF 22-pc. Set is indispensable

The VÖLKEL threading set stands out for its first-class quality and specialization in BSF threads. It is a must-have for anyone working with this special thread type and valuing precise results.

Ideal Application and Material Compatibility:

The HSS-G hand taps and HSS round dies included in the set are robust and versatile for:

- Materials with good machinability

- Unalloyed and low-alloy steels

- Through holes and blind holes

No matter whether you are cutting threads in old machines, vehicles, or special constructions, this set delivers the required precision.

High-Quality Components for Durability and Efficiency:

- HSS-G Hand Taps 2-pc. Set

The ground hand taps made of HSS according to DIN offer excellent cutting performance. Each size consists of a taper tap and a plug tap: - HSS Round Dies

For precise cutting of external threads – dimensionally accurate and wear-resistant: - Adjustable Tap Wrenches (Die Cast Zinc)

- Die Stocks (Die Cast Zinc)

- Ratchet Tap Wrench

- Size 1 (10001)

Flexibility and Reorderability:

All threading tools and accessories in this set can also be ordered separately – for maximum flexibility for additions or replacements.

Step-by-Step Instructions

Instructions for Cutting Internal Threads

Here's how to cut a precise **internal thread** with the hand tap set:

- Preparation: Select the appropriate tap and drill the core hole to the correct diameter. Apply generous amounts of cutting oil to the tap and into the hole to reduce friction and protect the tools.

- Tool Clamping: Clamp the taper tap (with the longer chamfer length) into the adjustable tap wrench.

- Pre-tapping: Insert the tap vertically into the drilled hole. Start turning the tool clockwise slowly and with even pressure.

- Finishing: Replace the taper tap with the plug tap (with the shorter chamfer length) and cut the thread to the desired depth.

- Cleaning: Carefully remove the tap and clean the finished **internal thread** and tools from chips and oil.

Instructions for Cutting External Threads

Here's how you can cut a precise **external thread**:

- Preparation: Select the appropriate round die and the bolt with the correct outer diameter. Apply generous amounts of cutting oil to the die and the bolt.

- Tool Clamping: Clamp the round die into the appropriate **threading tool holder** (die stock).

- Cutting the Thread: Begin turning the round die slowly and evenly clockwise with light pressure. Ensure vertical guidance.

- Completion: Cut the **external thread** to the desired length. Perform the cut in a continuous motion to achieve a clean result.

- Cleaning: Remove the **die stock** and clean the finished thread and the round die from chips and oil.

Frequently Asked Questions (FAQ)

1. What is the difference between a hand tap set and a machine tap?

A hand tap set, as included in this **tap and die set**, is typically used by hand with a tap wrench and consists of multiple parts to enable precise **internal thread cutting**. Machine taps are optimized for use in drilling machines or tapping machines and often cut the thread in a single operation.

2. What is the function of the taper tap and the plug tap?

The taper tap has a shorter chamfer length and initiates the threading process by preparing the material. The plug tap, with a longer chamfer length, completes the thread and ensures final precision and dimensional accuracy.

3. Can I cut other threads with this set?

No, this set is specifically designed for BSF threads. For cutting metric ISO threads or other thread types, you will need the corresponding **BSF threading tool set** or a separate set.

4. What is the advantage of HSS-G material?

HSS-G stands for High-Speed Steel with ground cutting surfaces. This leads to higher precision, a better surface finish of the thread, and a longer tool life, which is particularly important when **cutting external threads**.

5. What are BSF threads and what are they used for?

BSF stands for "British Standard Fine" and is a fine thread standard primarily used in Great Britain in older machines, vehicles, and bicycles. It is characterized by a larger core diameter and higher strength compared to metric threads.

Order now and rely on quality

Secure your VÖLKEL Hand Taps and Round Dies 22-piece Set BSF 1/4 – 1/2 now and master every challenge in the field of BSF threads with precision and reliability! For more information, visit our website or contact us via our contact form.

Recommended products

Related products