Machine Tap JIS B-4430 Form C 35° Spiral Flute HSS-G - Rc (BSPT) 1/16 x 28

€23.70

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

Machine Tap JIS B-4430 Form C 35° Spiral Flute HSS-G - Rc (BSPT) 1/16 x 28

The VÖLKEL machine tap according to JIS B-4430 in Form C 35° Spiral Flute, manufactured from HSS-G (ground high speed steel), is ideal for producing precise taper pipe threads Rc (BSPT). With a 1:16 taper and 55° flank angle, it ensures a secure, self-sealing fit. The Form C 35° Spiral Flute design makes it particularly suitable for blind holes and allows use in both manual and machine tapping.

Applications and Advantages

This machine tap is designed for the following applications:

- For general use in metalworking.

- Suitable for non-abrasive materials up to 900 N/mm², especially unalloyed and low alloyed steels.

- Usable for manual and machine tapping.

- Particularly suitable for blind holes.

- Taper pipe thread Rc (BSPT), taper 1:16, 55° flank angle – self-sealing.

Step-by-Step Guide (Manual Tapping)

- Preparation: Drill the core hole with the correct nominal diameter for Rc 1/16 x 28. Deburr the hole carefully.

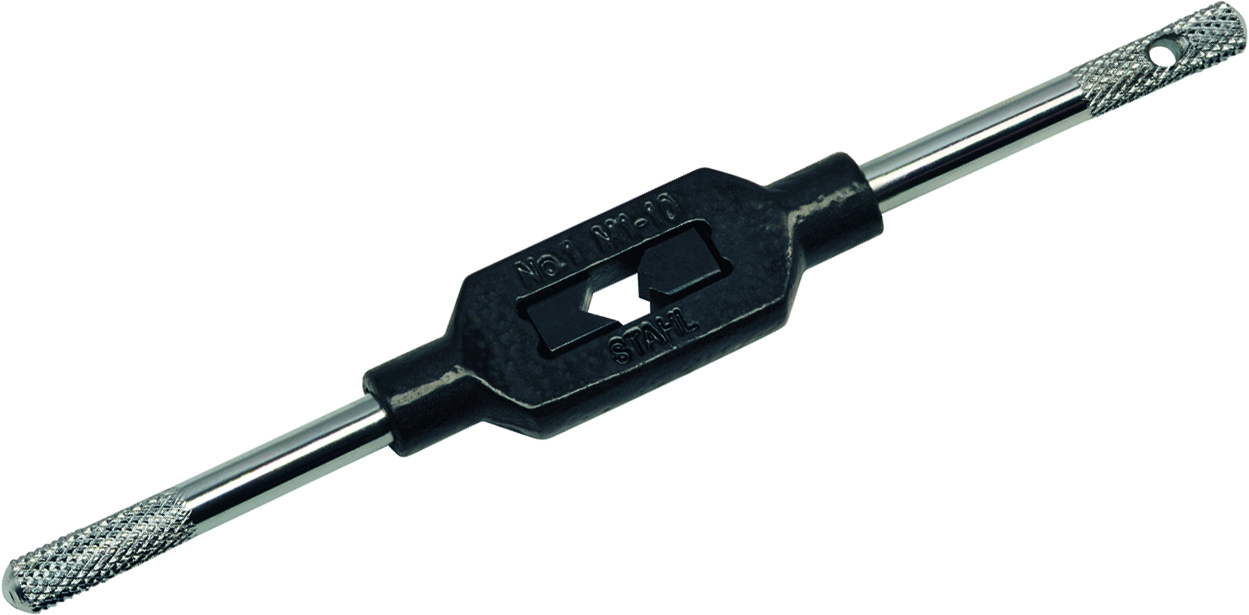

- Clamping: Secure the tap firmly and perpendicular in a tap wrench or machine holder.

- Lubrication: Apply cutting oil generously to both the tool and the hole.

- Starting: Position the tap vertically and rotate clockwise with steady pressure until it cuts in.

- Tapping: Continue rotating smoothly. The 35° spiral flute aids chip evacuation in blind holes. Reapply lubricant regularly.

- Finishing: Once the required depth is reached, carefully remove the tap by rotating counterclockwise.

- Inspection: Clean the finished thread and check it with a gauge or mating part.

Technical Data (Rc 1/16 x 28)

- Thread type Rc (BSPT) – taper pipe thread

- Taper/Angle 1:16 taper, 55° flank angle

- Form Form C 35° Spiral Flute (JIS B-4430)

- Material HSS-G (ground high speed steel)

- Nominal size PT 1/16 x 28

- Overall length (L1) 55 mm

- Thread length (L2) 17.5 mm

- Shank diameter (D2) 8 mm

- Drive square 6 mm

- EAN 4022835977025

- Article number 97702

- Application Hand and machine use; blind holes; steels ≤ 900 N/mm²

FAQ – Frequently Asked Questions

Q1: What is the difference between Rc and R threads?

A1: Rc refers to the internal taper pipe thread (BSPT), while R refers to the external taper pipe thread. Both are conical (1:16) with a 55° flank angle and provide self-sealing connections.

Q2: What does Form C 35° Spiral Flute mean?

A2: The Form C 35° Spiral Flute design optimizes chip evacuation, especially in blind holes, ensuring cleaner and more reliable threading.

Q3: What are the benefits of HSS-G?

A3: HSS-G (ground high speed steel) offers high accuracy, extended tool life, and smoother thread surfaces.

Q4: Which materials can this tap be used on?

A4: Suitable for non-abrasive materials up to 900 N/mm², particularly unalloyed and low alloy steels.

Q5: Can this tap be used manually and with machines?

A5: Yes, it is designed for universal use in both hand and machine tapping, provided proper clamping and lubrication are applied.

Do you have specific questions about the use of this machine tap or need advice for other thread types? We are happy to assist! You can reach us anytime via our contact form.

| Type of thread | tapered pipe thread, taper 1:16, con. 55° |

|---|---|

| Standard | JIS B-4430 |

| Form | Form C |

| Material | HSS-G |

| Tolerance | medium |

| Size | Rc (BSPT) 1/16 x 28 |

| Overall length (L1) | 55 mm |

| Thread length (L2) | 19 mm |

| Core hole diameter (D1) | 6.3 mm |

| Shank diameter (D2) | 8.0 mm |

| Drive connector | 6.0 mm |

| EAN | 4022835977025 |

| Item number | 97702 |

| Type of flute | 35° Spiral Flute |

| Application | for blind holes |

| Thread standard | ISO 7-1 |

Machine Tap JIS B-4430 Form C 35° Spiral Flute HSS-G - Rc (BSPT) 1/16 x 28

The VÖLKEL machine tap according to JIS B-4430 in Form C 35° Spiral Flute, manufactured from HSS-G (ground high speed steel), is ideal for producing precise taper pipe threads Rc (BSPT). With a 1:16 taper and 55° flank angle, it ensures a secure, self-sealing fit. The Form C 35° Spiral Flute design makes it particularly suitable for blind holes and allows use in both manual and machine tapping.

Applications and Advantages

This machine tap is designed for the following applications:

- For general use in metalworking.

- Suitable for non-abrasive materials up to 900 N/mm², especially unalloyed and low alloyed steels.

- Usable for manual and machine tapping.

- Particularly suitable for blind holes.

- Taper pipe thread Rc (BSPT), taper 1:16, 55° flank angle – self-sealing.

Step-by-Step Guide (Manual Tapping)

- Preparation: Drill the core hole with the correct nominal diameter for Rc 1/16 x 28. Deburr the hole carefully.

- Clamping: Secure the tap firmly and perpendicular in a tap wrench or machine holder.

- Lubrication: Apply cutting oil generously to both the tool and the hole.

- Starting: Position the tap vertically and rotate clockwise with steady pressure until it cuts in.

- Tapping: Continue rotating smoothly. The 35° spiral flute aids chip evacuation in blind holes. Reapply lubricant regularly.

- Finishing: Once the required depth is reached, carefully remove the tap by rotating counterclockwise.

- Inspection: Clean the finished thread and check it with a gauge or mating part.

Technical Data (Rc 1/16 x 28)

- Thread type Rc (BSPT) – taper pipe thread

- Taper/Angle 1:16 taper, 55° flank angle

- Form Form C 35° Spiral Flute (JIS B-4430)

- Material HSS-G (ground high speed steel)

- Nominal size PT 1/16 x 28

- Overall length (L1) 55 mm

- Thread length (L2) 17.5 mm

- Shank diameter (D2) 8 mm

- Drive square 6 mm

- EAN 4022835977025

- Article number 97702

- Application Hand and machine use; blind holes; steels ≤ 900 N/mm²

FAQ – Frequently Asked Questions

Q1: What is the difference between Rc and R threads?

A1: Rc refers to the internal taper pipe thread (BSPT), while R refers to the external taper pipe thread. Both are conical (1:16) with a 55° flank angle and provide self-sealing connections.

Q2: What does Form C 35° Spiral Flute mean?

A2: The Form C 35° Spiral Flute design optimizes chip evacuation, especially in blind holes, ensuring cleaner and more reliable threading.

Q3: What are the benefits of HSS-G?

A3: HSS-G (ground high speed steel) offers high accuracy, extended tool life, and smoother thread surfaces.

Q4: Which materials can this tap be used on?

A4: Suitable for non-abrasive materials up to 900 N/mm², particularly unalloyed and low alloy steels.

Q5: Can this tap be used manually and with machines?

A5: Yes, it is designed for universal use in both hand and machine tapping, provided proper clamping and lubrication are applied.

Do you have specific questions about the use of this machine tap or need advice for other thread types? We are happy to assist! You can reach us anytime via our contact form.

Recommended products

97702