Short Machine Tap Form C HSS-G - Rc (BSPT) 1/8 x 28

€8.50

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

VÖLKEL Short Machine Tap Form C HSS-G - Rc (BSPT) 1/8 x 28

The VÖLKEL Short Machine Tap in Form C, made from HSS-G (High-Speed Steel Ground), is the ideal solution for reliably cutting taper pipe threads according to British Standard Pipe Taper (BSPT). The Rc thread, with its 1:16 taper, ensures a tight, metal-to-metal seal when applied correctly. This tool is primarily designed for blind holes and is perfectly suited for use in unalloyed and low alloyed steels up to 900 N/mm² when cutting threads by hand.

Application Notes and Advantages

This tap delivers optimal results in the following application areas:

- Application: For general use in metalworking.

- Suitable Materials: Non-abrasive materials up to 900 N/mm², especially unalloyed and low alloyed steel.

- Design Focus: Optimally suited for cutting threads in **blind holes**.

- Usage: Primarily intended for thread cutting by hand.

- Thread Type: Taper pipe thread (Rc/BSPT), 1:16 taper, 55° flank angle – a self-sealing thread.

Step-by-Step Guide (Hand Tapping)

- Preparation: Drill the core hole using the correct nominal core hole diameter. A special core hole size is required for the taper pipe thread to account for the taper. Deburr the hole.

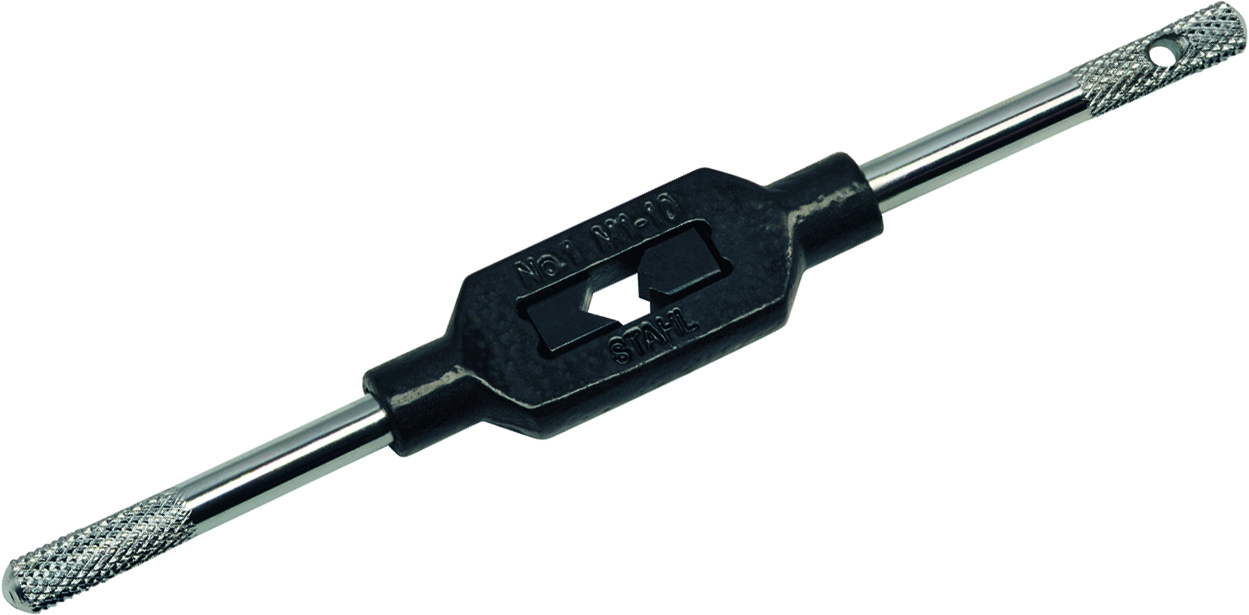

- Clamping: Securely clamp the tap into a tap wrench or a suitable holder. Ensure a firm, perpendicular alignment to the hole.

- Lubrication: Generously apply high-quality cutting oil to the tap and the hole. This is crucial for tool life and thread quality.

- Starting the Cut: Position the tap perpendicularly. Begin turning it slowly and with light pressure clockwise into the hole until it grips cleanly.

- Thread Cutting: Guide the tap into the material in a smooth, continuous rotational movement. The HSS-G design ensures good chip evacuation. Ensure a constant supply of cutting oil.

- Completion: Once the desired thread depth (or the full thread length) is reached, carefully turn the tap counter-clockwise completely out of the hole.

- Cleaning and Inspection: Clean the finished thread of chips and check its accuracy with a suitable thread plug gauge or counterpart.

Technical Features (Rc 1/8 x 28)

- Thread TypeRc (BSPT) Taper Pipe Thread

- Taper/AngleTaper 1:16, con. 55° Form

- MaterialHSS-G (High-Speed Steel Ground)

- Nominal Size1/8 x 28

- Overall Length (L1)65 mm

- Thread Length (L2)19 mm

- Shank Diameter (D2)7 mm

- Drive Square5.5 mm

- EAN4022835637127

- Item Number63712

Frequently Asked Questions (FAQ)

Q1: What is the difference between Rc and R threads?

A1: Rc stands for the tapered internal thread, while R refers to the corresponding tapered external thread. Both thread forms are conical (1:16) and manufactured according to the BSPT standard to ensure a sealed connection.

Q2: What does the specification "Taper 1:16" mean?

A2: The 1:16 taper describes the gradual decrease in the thread diameter. This means the diameter reduces by one unit over 16 units of length. This form is crucial for the self-sealing effect of the pipe thread.

Q3: What are the advantages of HSS-G?

A3: HSS-G stands for High-Speed Steel that has been ground (G=ground). This results in higher precision of the cutting edges, better surface quality of the manufactured threads, and increased tool life compared to conventional HSS tools.

Q4: Why is Form C suitable for blind holes?

A4: Form C (with approx. 3.5 to 5 threads chamfer) provides a good balance. It allows for an easy start and offers sufficient chip space for blind holes. Note that since this is an Rc (taper) thread, the threading depth is naturally limited by the taper.

Q5: Is lubrication required when tapping with this tool?

A5: Yes. Although HSS-G is robust, a suitable cutting oil or coolant should always be used to maximize tool life, reduce friction, and achieve optimal thread surface quality. This is particularly important for harder or long-chipping steels.

Do you have specific questions about the application of the short machine tap or need advice on selecting the right thread type? We are happy to help! You can reach us at any time via our contact form.

| Type of thread | tapered pipe thread, taper 1:16, con. 55° |

|---|---|

| Standard | DIN |

| Form | Form C |

| Material | HSS-G |

| Tolerance | medium |

| Size | Rc (BSPT) 1/8 x 28 |

| Overall length (L1) | 65 mm |

| Thread length (L2) | 19 mm |

| Core hole diameter (D1) | 8.2 mm |

| Shank diameter (D2) | 7.0 mm |

| Drive connector | 5.5 mm |

| EAN | 4022835637127 |

| Item number | 63712 |

| Type of flute | straight fluted |

| Application | for through and blind holes |

| Thread standard | ISO 7-1 |

VÖLKEL Short Machine Tap Form C HSS-G - Rc (BSPT) 1/8 x 28

The VÖLKEL Short Machine Tap in Form C, made from HSS-G (High-Speed Steel Ground), is the ideal solution for reliably cutting taper pipe threads according to British Standard Pipe Taper (BSPT). The Rc thread, with its 1:16 taper, ensures a tight, metal-to-metal seal when applied correctly. This tool is primarily designed for blind holes and is perfectly suited for use in unalloyed and low alloyed steels up to 900 N/mm² when cutting threads by hand.

Application Notes and Advantages

This tap delivers optimal results in the following application areas:

- Application: For general use in metalworking.

- Suitable Materials: Non-abrasive materials up to 900 N/mm², especially unalloyed and low alloyed steel.

- Design Focus: Optimally suited for cutting threads in **blind holes**.

- Usage: Primarily intended for thread cutting by hand.

- Thread Type: Taper pipe thread (Rc/BSPT), 1:16 taper, 55° flank angle – a self-sealing thread.

Step-by-Step Guide (Hand Tapping)

- Preparation: Drill the core hole using the correct nominal core hole diameter. A special core hole size is required for the taper pipe thread to account for the taper. Deburr the hole.

- Clamping: Securely clamp the tap into a tap wrench or a suitable holder. Ensure a firm, perpendicular alignment to the hole.

- Lubrication: Generously apply high-quality cutting oil to the tap and the hole. This is crucial for tool life and thread quality.

- Starting the Cut: Position the tap perpendicularly. Begin turning it slowly and with light pressure clockwise into the hole until it grips cleanly.

- Thread Cutting: Guide the tap into the material in a smooth, continuous rotational movement. The HSS-G design ensures good chip evacuation. Ensure a constant supply of cutting oil.

- Completion: Once the desired thread depth (or the full thread length) is reached, carefully turn the tap counter-clockwise completely out of the hole.

- Cleaning and Inspection: Clean the finished thread of chips and check its accuracy with a suitable thread plug gauge or counterpart.

Technical Features (Rc 1/8 x 28)

- Thread TypeRc (BSPT) Taper Pipe Thread

- Taper/AngleTaper 1:16, con. 55° Form

- MaterialHSS-G (High-Speed Steel Ground)

- Nominal Size1/8 x 28

- Overall Length (L1)65 mm

- Thread Length (L2)19 mm

- Shank Diameter (D2)7 mm

- Drive Square5.5 mm

- EAN4022835637127

- Item Number63712

Frequently Asked Questions (FAQ)

Q1: What is the difference between Rc and R threads?

A1: Rc stands for the tapered internal thread, while R refers to the corresponding tapered external thread. Both thread forms are conical (1:16) and manufactured according to the BSPT standard to ensure a sealed connection.

Q2: What does the specification "Taper 1:16" mean?

A2: The 1:16 taper describes the gradual decrease in the thread diameter. This means the diameter reduces by one unit over 16 units of length. This form is crucial for the self-sealing effect of the pipe thread.

Q3: What are the advantages of HSS-G?

A3: HSS-G stands for High-Speed Steel that has been ground (G=ground). This results in higher precision of the cutting edges, better surface quality of the manufactured threads, and increased tool life compared to conventional HSS tools.

Q4: Why is Form C suitable for blind holes?

A4: Form C (with approx. 3.5 to 5 threads chamfer) provides a good balance. It allows for an easy start and offers sufficient chip space for blind holes. Note that since this is an Rc (taper) thread, the threading depth is naturally limited by the taper.

Q5: Is lubrication required when tapping with this tool?

A5: Yes. Although HSS-G is robust, a suitable cutting oil or coolant should always be used to maximize tool life, reduce friction, and achieve optimal thread surface quality. This is particularly important for harder or long-chipping steels.

Do you have specific questions about the application of the short machine tap or need advice on selecting the right thread type? We are happy to help! You can reach us at any time via our contact form.

Recommended products

63712