Machine Tap JIS B-4430 Form C HSS-G - Rp (BSPP) 1/16 x 28

€15.40

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

Machine Tap JIS B-4430 Form C HSS-G - Rp (BSPP) 1/16 x 28

The VÖLKEL machine tap according to JIS B-4430 in Form C, made of HSS-G (ground high-speed steel), is the perfect tool for producing cylindrical pipe threads Rp (BSPP) according to ISO 7-1. The Rp internal thread with a 55° flank angle is typically combined with a conical R external thread to achieve a pressure-tight connection. Form C is suitable for both through and blind holes and can be used by hand or machine.

Application and Benefits

With this machine tap, you benefit from the following advantages:

- For general use in metalworking.

- Suitable for non-abrasive materials up to 900 N/mm², especially unalloyed and low-alloyed steels.

- Can be used for hand and machine thread cutting.

- Ideal for through and blind holes.

- Cylindrical pipe thread Rp (BSPP) according to ISO 7-1, 55° flank angle – designed for pressure-tight connections with conical R external threads.

Step-by-Step Guide (Hand Tapping)

- Preparation: Drill the core hole with the correct nominal diameter for Rp/BSPP 1/16 x 28. Deburr the hole carefully.

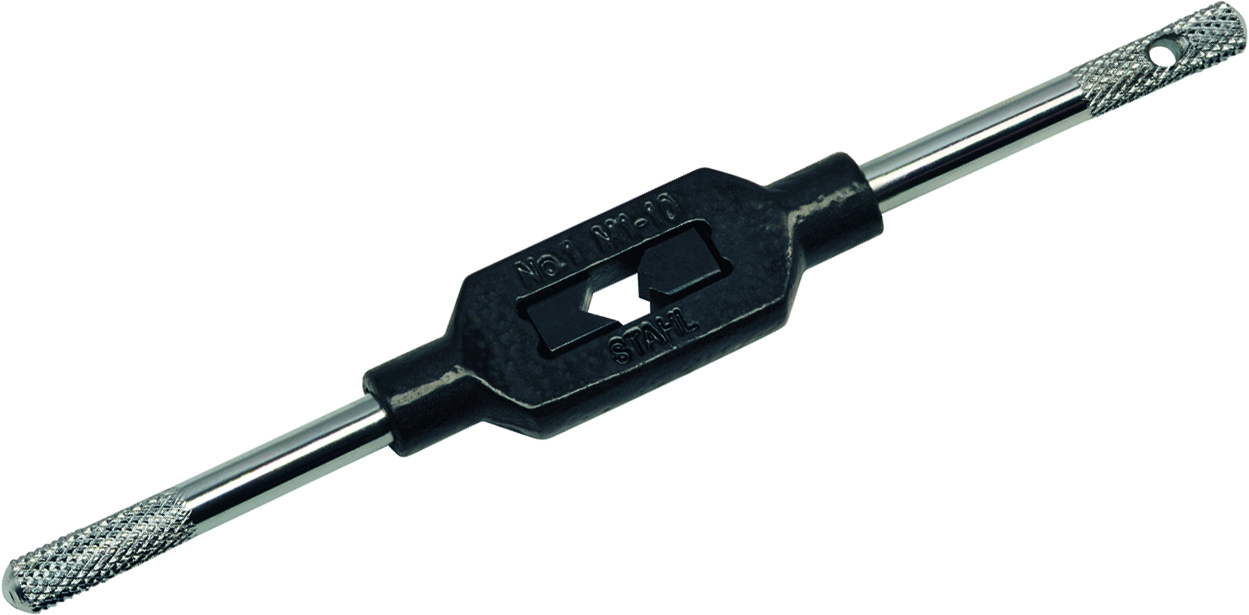

- Clamping: Securely clamp the tap vertically in a tap wrench or machine holder.

- Lubrication: Apply plenty of high-quality cutting oil to the tool and the hole.

- Starting: Position the tap exactly vertical and start turning clockwise with steady pressure until it engages cleanly.

- Tapping: Continue with a smooth, steady rotation. Ensure regular lubrication during the process.

- Finishing: Once the desired depth is reached, carefully turn the tap counterclockwise to remove it completely.

- Inspection: Clean the finished thread and check it with a suitable thread gauge or matching part.

Technical Data (Rp 1/16 x 28)

- Thread type Rp (BSPP) – cylindrical pipe thread ISO 7-1

- Angle 55° flank angle (Whitworth profile)

- Form Form C (JIS B-4430)

- Material HSS-G (ground high-speed steel)

- Nominal size PS 1/16 x 28

- Overall length (L1) 55 mm

- Thread length (L2) 19 mm

- Shank diameter (D2) 6.5 mm

- Square drive 5 mm

- EAN 4022835954026

- Article number 95402

- Application Hand and machine use; through & blind holes; steels ≤ 900 N/mm²

FAQ – Frequently Asked Questions

Q1: What is the difference between Rp (BSPP) and Rc (BSPT)?

A1: Rp is a cylindrical internal thread (BSPP) according to ISO 7-1, while Rc is a tapered internal thread (BSPT). Rp threads are sealed pressure-tight when combined with R (tapered) external threads.

Q2: What is Form C used for?

A2: Form C (medium chamfer length) is versatile and suitable for through and blind holes, offering good starting and sufficient chip space.

Q3: What are the advantages of HSS-G?

A3: HSS-G provides you with high precision, clean thread surfaces, and longer tool life thanks to ground cutting edges.

Q4: Which materials are suitable?

A4: All non-abrasive materials up to 900 N/mm², especially unalloyed and low-alloy steels.

Q5: Can you use this tap both by hand and machine?

A5: Yes, it is designed for both applications. Just make sure to clamp it correctly and apply proper lubrication.

Do you have specific questions about using this machine tap or need advice on other thread types? We're happy to help! Just reach out via our contact form.

| Type of thread | pipe thread |

|---|---|

| Standard | JIS B-4430 |

| Form | Form C |

| Material | HSS-G |

| Tolerance | medium |

| Size | Rp (BSPP) 1/16 x 28 |

| Overall length (L1) | 55 mm |

| Thread length (L2) | 19 mm |

| Core hole diameter (D1) | 6.6 mm |

| Shank diameter (D2) | 6.5 mm |

| Drive connector | 5.0 mm |

| EAN | 4022835954026 |

| Item number | 95402 |

| Type of flute | straight fluted |

| Application | for through and blind holes |

| Thread standard | ISO 7-1 (DIN EN 10226-1) |

Machine Tap JIS B-4430 Form C HSS-G - Rp (BSPP) 1/16 x 28

The VÖLKEL machine tap according to JIS B-4430 in Form C, made of HSS-G (ground high-speed steel), is the perfect tool for producing cylindrical pipe threads Rp (BSPP) according to ISO 7-1. The Rp internal thread with a 55° flank angle is typically combined with a conical R external thread to achieve a pressure-tight connection. Form C is suitable for both through and blind holes and can be used by hand or machine.

Application and Benefits

With this machine tap, you benefit from the following advantages:

- For general use in metalworking.

- Suitable for non-abrasive materials up to 900 N/mm², especially unalloyed and low-alloyed steels.

- Can be used for hand and machine thread cutting.

- Ideal for through and blind holes.

- Cylindrical pipe thread Rp (BSPP) according to ISO 7-1, 55° flank angle – designed for pressure-tight connections with conical R external threads.

Step-by-Step Guide (Hand Tapping)

- Preparation: Drill the core hole with the correct nominal diameter for Rp/BSPP 1/16 x 28. Deburr the hole carefully.

- Clamping: Securely clamp the tap vertically in a tap wrench or machine holder.

- Lubrication: Apply plenty of high-quality cutting oil to the tool and the hole.

- Starting: Position the tap exactly vertical and start turning clockwise with steady pressure until it engages cleanly.

- Tapping: Continue with a smooth, steady rotation. Ensure regular lubrication during the process.

- Finishing: Once the desired depth is reached, carefully turn the tap counterclockwise to remove it completely.

- Inspection: Clean the finished thread and check it with a suitable thread gauge or matching part.

Technical Data (Rp 1/16 x 28)

- Thread type Rp (BSPP) – cylindrical pipe thread ISO 7-1

- Angle 55° flank angle (Whitworth profile)

- Form Form C (JIS B-4430)

- Material HSS-G (ground high-speed steel)

- Nominal size PS 1/16 x 28

- Overall length (L1) 55 mm

- Thread length (L2) 19 mm

- Shank diameter (D2) 6.5 mm

- Square drive 5 mm

- EAN 4022835954026

- Article number 95402

- Application Hand and machine use; through & blind holes; steels ≤ 900 N/mm²

FAQ – Frequently Asked Questions

Q1: What is the difference between Rp (BSPP) and Rc (BSPT)?

A1: Rp is a cylindrical internal thread (BSPP) according to ISO 7-1, while Rc is a tapered internal thread (BSPT). Rp threads are sealed pressure-tight when combined with R (tapered) external threads.

Q2: What is Form C used for?

A2: Form C (medium chamfer length) is versatile and suitable for through and blind holes, offering good starting and sufficient chip space.

Q3: What are the advantages of HSS-G?

A3: HSS-G provides you with high precision, clean thread surfaces, and longer tool life thanks to ground cutting edges.

Q4: Which materials are suitable?

A4: All non-abrasive materials up to 900 N/mm², especially unalloyed and low-alloy steels.

Q5: Can you use this tap both by hand and machine?

A5: Yes, it is designed for both applications. Just make sure to clamp it correctly and apply proper lubrication.

Do you have specific questions about using this machine tap or need advice on other thread types? We're happy to help! Just reach out via our contact form.

Recommended products

95402