1. What is the difference between BSF and BSW threads?

BSF (British Standard Fine) and BSW (British Standard Whitworth) are both British thread standards. The main difference lies in the thread pitch. BSF threads have a finer pitch and are generally used for applications requiring higher strength and finer adjustment. BSW threads are coarser and are often used for more general fastening tasks.

2. What is the outer diameter of the die?

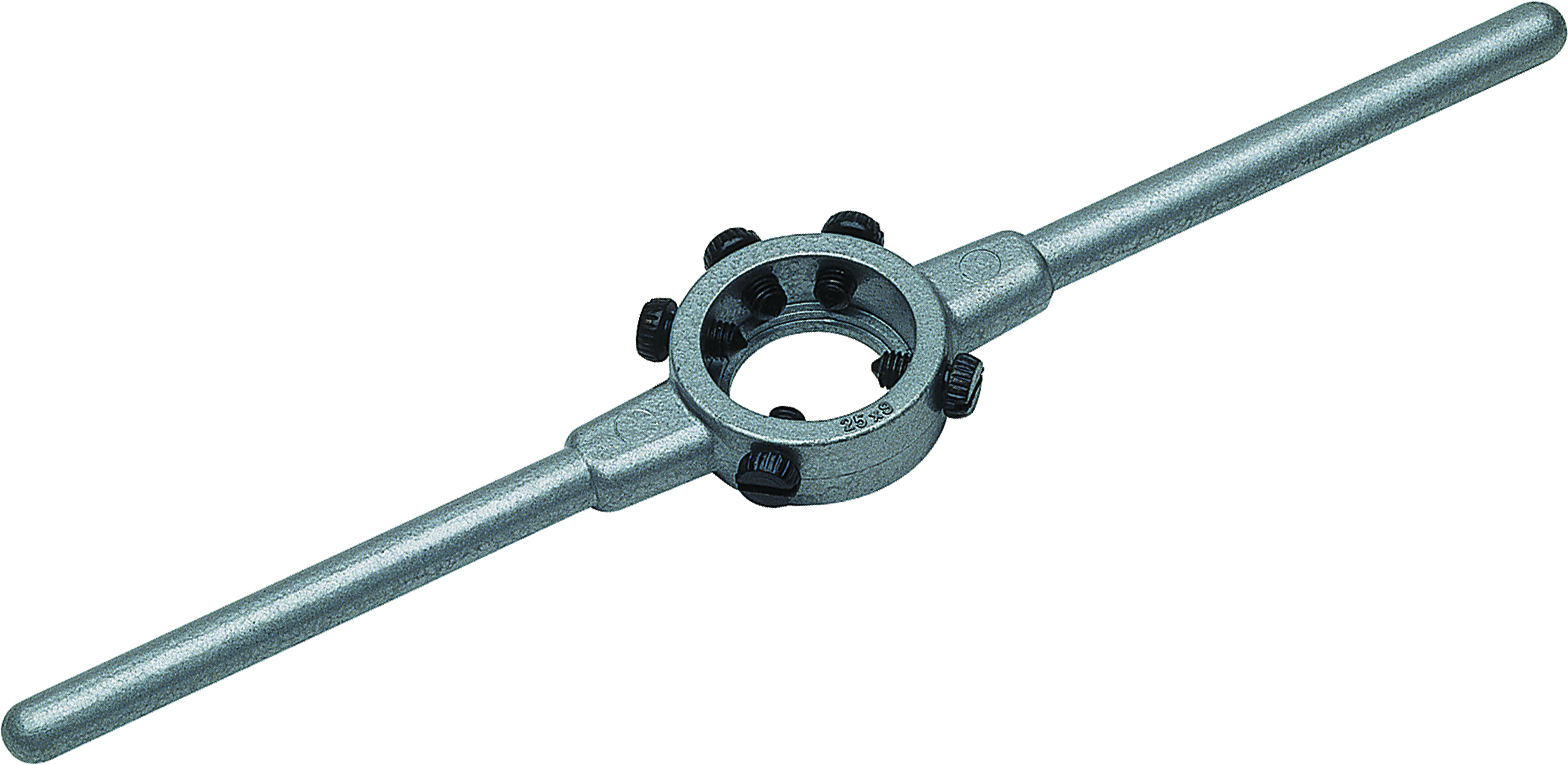

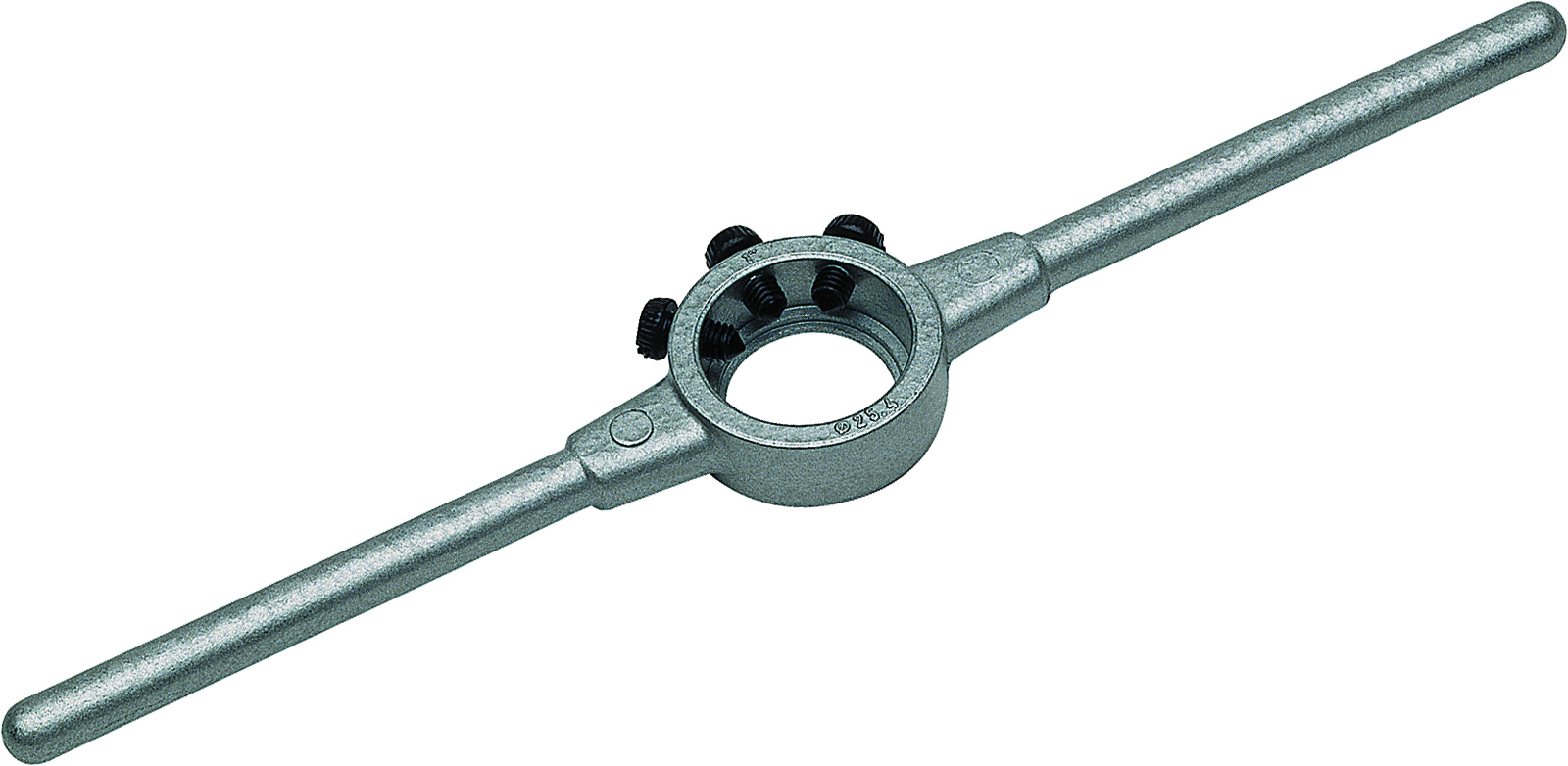

The die has an outer diameter of 1.5/16 inches (o/d). This outer diameter is standardized and ensures that the die fits into the corresponding die stocks.

3. What does HSS stand for?

HSS stands for "High Speed Steel." It is an alloyed tool steel that retains its hardness and cutting performance even at high temperatures that can arise during machining. This makes HSS tools very wear-resistant and durable.

4. Can I use this die for stainless steel?

This die is primarily designed for easy-to-machine materials up to 800 N/mm², such as unalloyed and low-alloy steels. For stainless steel, which generally has higher strength and toughness, we recommend using dies made of HSS-E (with cobalt additive) or solid carbide, as these materials offer better heat dissipation and higher hardness for such demanding applications.

5. How do I maintain the die to extend its service life?

After each use, the die should be thoroughly cleaned of chips and residues. Store it in a dry, protected place to prevent corrosion and mechanical damage. Applying a light rust-preventative oil before storage is also recommended. Regular maintenance significantly contributes to extending the service life and maintaining the cutting performance.