Round Die DIN 223 (DIN EN 22568) HSSE VAP - M 3 x 0.5

€24.00

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

VÖLKEL Round Die DIN 223 HSSE VAP - M 3 x 0.5

The VÖLKEL Round Die in the high-performance HSSE VAP (vaporized) version is the ideal tool for professional external thread production of size M 3 x 0.5. The closed form (Form B) according to DIN 223 (DIN EN 22568) ensures high stability. The vaporized material (VAP treatment) optimizes the absorption of cutting oil, leading to a significantly increased service life and excellent cutting results. This die is designed for both manual use with a die stock and for machine use, and is particularly suitable for processing tough and stainless materials.

Step-by-Step Guide for Thread Cutting (Manual Use)

- Preparation: Turn the round bar or shaft down to the nominal thread diameter (here 3.0 mm). Lightly chamfer the edges to facilitate the initial cut. Fix the workpiece securely in the vise or clamping device.

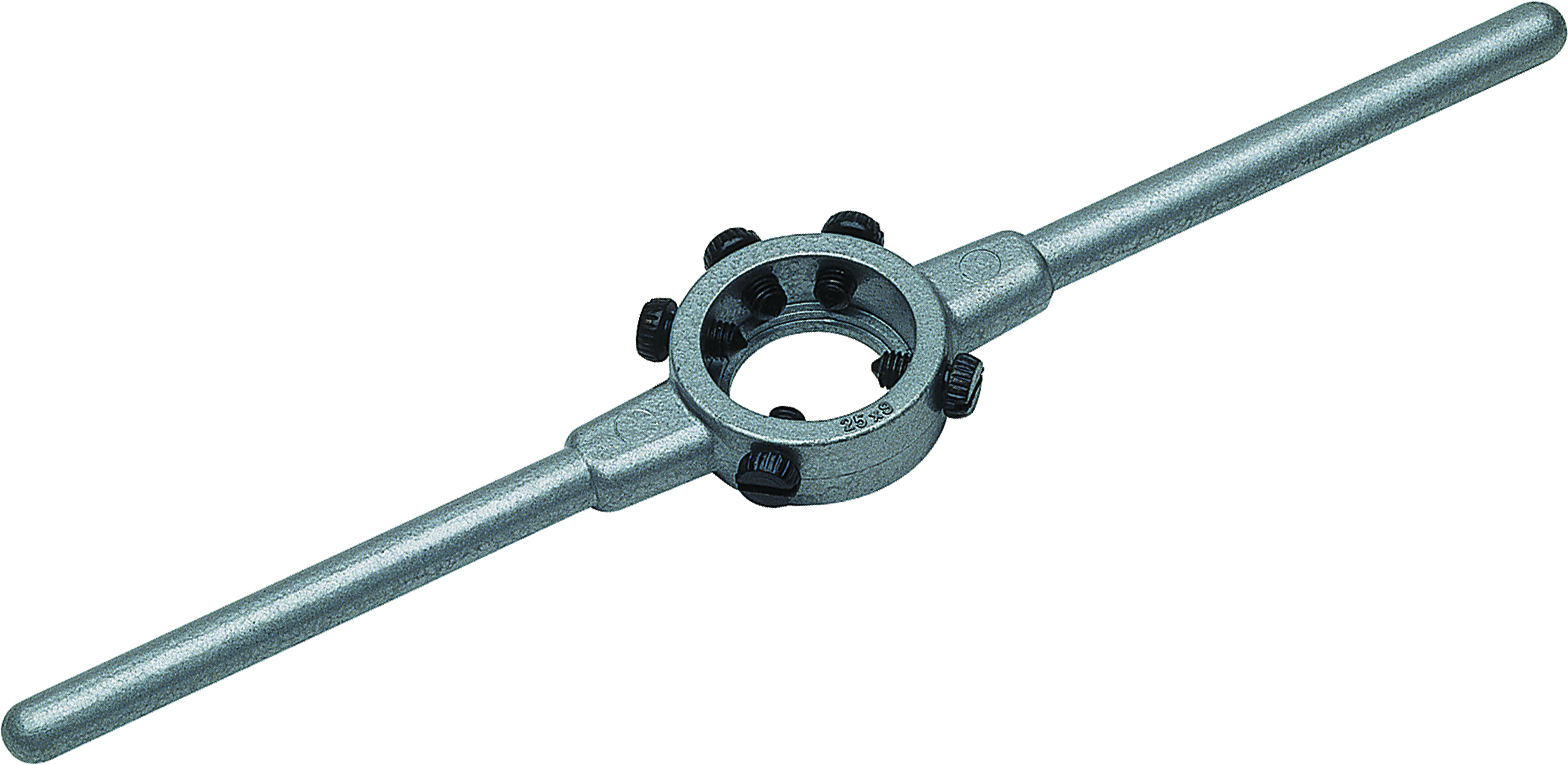

- Clamping: Insert the round die into the appropriate die stock and secure it firmly with the clamping screws (Form B).

- Lubrication: Before starting, generously apply cutting oil to the die and the start of the workpiece. The VAP surface helps to retain the oil optimally.

- Starting the Cut: Place the die perpendicularly to the workpiece axis. Press lightly and turn the die stock clockwise evenly. The chamfer assists with centered cutting.

- Cutting Process: Turn the die continuously clockwise to cut the thread, ensuring a constant supply of lubricant.

- Final Check: Once the desired thread has been cut, carefully turn the die off completely. Check the thread using a suitable thread ring gauge or nut.

Application and Advantages

Application Areas:

- Alloyed tough materials up to 1200 N/mm²

- Stainless steels (Stainless steel)

- Cast aluminum

- Spheroidal graphite cast iron (GGG)

Advantages of the HSSE VAP Version:

- High cutting edge retention and wear resistance

- Easy cutting and low friction

- Free chip evacuation to the front, preventing clogging of chip holes

- The vaporized surface (VAP) ensures optimal adhesion of the cutting oil

- Suitable for manual and machine use

Technical Features and Standards

- Thread Type: Metric ISO Thread

- Standard: DIN 223 (DIN EN 22568)

- Form: Closed Design (Form B) High Performance

- Material: HSSE (High-Speed Steel with Cobalt) VAP (Vaporized)

- Tolerance: 6g (Standard tolerance for general fits)

- Nominal Size: M 3 x 0.5

- Outer Diameter: 20.0 mm

- EAN: 4022835578260

- Item Number: 57826

Blog Post, Video, and Further Information

Would you like to learn more about the advantages of our premium dies? Read our blog post:

Round Dies VX – The Premium Cutting Tool from VÖLKEL

Watch this video from the VÖLKEL Threading Solutions channel to see our dies in action:

VÖLKEL Schneideisen / Round Die VX (Video length: 1 minute, 12 seconds)

The information applies to the quality and application areas of the HSSE VAP die presented here.

Frequently Asked Questions (FAQ)

Q1: What does the designation HSSE VAP mean?

A1: HSSE stands for High-Speed Steel with Cobalt, offering higher hardness and hot hardness than HSS. VAP (Vaporized) is a surface treatment that improves the adhesion of cutting oil, thereby extending tool life, especially for tough and stainless materials.

Q2: Which materials is this die particularly suitable for?

A2: Due to the HSSE VAP material, it is ideal for demanding materials such as stainless steels, high-strength alloyed steels up to 1200 N/mm², as well as cast aluminum and spheroidal graphite cast iron (GGG).

Q3: What is the advantage of the closed Form B?

A3: The closed form (Form B) is very stable. It is clamped in the die stock with an adjusting screw and is particularly suitable for machine use or for manual applications where high stability is required.

Q4: What does the tolerance 6g indicate?

A4: The 6g tolerance is the common standard tolerance for external threads. It ensures a normal, clearance-free fit to an internal thread with a 6H tolerance (the common standard for internal threads).

Q5: Can I use this die without cutting oil?

A5: For optimal results, maximum tool life, and a clean cut, especially with stainless or tough materials, the use of high-quality cutting oil is strongly recommended. The VAP treatment further supports the effect of the cutting oil.

Do you have specific requirements or need advice on choosing the right threading tool? We are happy to help you! You can reach us anytime via our contact form.

| Type of thread | metric ISO-thread |

|---|---|

| Standard | DIN 223 (DIN EN 22568) |

| Form | solid version (Form B) High Performance |

| Material | HSSE |

| Tolerance | 6g |

| Size | M 3 x 0.5 |

| Outer diameter | 20.0 mm |

| EAN | 4022835578260 |

| Item number | 57826 |

| Thread standard | DIN 13 |

| Coating | VAP |

| Rec. Bolt diameter | 2.92 mm |

VÖLKEL Round Die DIN 223 HSSE VAP - M 3 x 0.5

The VÖLKEL Round Die in the high-performance HSSE VAP (vaporized) version is the ideal tool for professional external thread production of size M 3 x 0.5. The closed form (Form B) according to DIN 223 (DIN EN 22568) ensures high stability. The vaporized material (VAP treatment) optimizes the absorption of cutting oil, leading to a significantly increased service life and excellent cutting results. This die is designed for both manual use with a die stock and for machine use, and is particularly suitable for processing tough and stainless materials.

Step-by-Step Guide for Thread Cutting (Manual Use)

- Preparation: Turn the round bar or shaft down to the nominal thread diameter (here 3.0 mm). Lightly chamfer the edges to facilitate the initial cut. Fix the workpiece securely in the vise or clamping device.

- Clamping: Insert the round die into the appropriate die stock and secure it firmly with the clamping screws (Form B).

- Lubrication: Before starting, generously apply cutting oil to the die and the start of the workpiece. The VAP surface helps to retain the oil optimally.

- Starting the Cut: Place the die perpendicularly to the workpiece axis. Press lightly and turn the die stock clockwise evenly. The chamfer assists with centered cutting.

- Cutting Process: Turn the die continuously clockwise to cut the thread, ensuring a constant supply of lubricant.

- Final Check: Once the desired thread has been cut, carefully turn the die off completely. Check the thread using a suitable thread ring gauge or nut.

Application and Advantages

Application Areas:

- Alloyed tough materials up to 1200 N/mm²

- Stainless steels (Stainless steel)

- Cast aluminum

- Spheroidal graphite cast iron (GGG)

Advantages of the HSSE VAP Version:

- High cutting edge retention and wear resistance

- Easy cutting and low friction

- Free chip evacuation to the front, preventing clogging of chip holes

- The vaporized surface (VAP) ensures optimal adhesion of the cutting oil

- Suitable for manual and machine use

Technical Features and Standards

- Thread Type: Metric ISO Thread

- Standard: DIN 223 (DIN EN 22568)

- Form: Closed Design (Form B) High Performance

- Material: HSSE (High-Speed Steel with Cobalt) VAP (Vaporized)

- Tolerance: 6g (Standard tolerance for general fits)

- Nominal Size: M 3 x 0.5

- Outer Diameter: 20.0 mm

- EAN: 4022835578260

- Item Number: 57826

Blog Post, Video, and Further Information

Would you like to learn more about the advantages of our premium dies? Read our blog post:

Round Dies VX – The Premium Cutting Tool from VÖLKEL

Watch this video from the VÖLKEL Threading Solutions channel to see our dies in action:

VÖLKEL Schneideisen / Round Die VX (Video length: 1 minute, 12 seconds)

The information applies to the quality and application areas of the HSSE VAP die presented here.

Frequently Asked Questions (FAQ)

Q1: What does the designation HSSE VAP mean?

A1: HSSE stands for High-Speed Steel with Cobalt, offering higher hardness and hot hardness than HSS. VAP (Vaporized) is a surface treatment that improves the adhesion of cutting oil, thereby extending tool life, especially for tough and stainless materials.

Q2: Which materials is this die particularly suitable for?

A2: Due to the HSSE VAP material, it is ideal for demanding materials such as stainless steels, high-strength alloyed steels up to 1200 N/mm², as well as cast aluminum and spheroidal graphite cast iron (GGG).

Q3: What is the advantage of the closed Form B?

A3: The closed form (Form B) is very stable. It is clamped in the die stock with an adjusting screw and is particularly suitable for machine use or for manual applications where high stability is required.

Q4: What does the tolerance 6g indicate?

A4: The 6g tolerance is the common standard tolerance for external threads. It ensures a normal, clearance-free fit to an internal thread with a 6H tolerance (the common standard for internal threads).

Q5: Can I use this die without cutting oil?

A5: For optimal results, maximum tool life, and a clean cut, especially with stainless or tough materials, the use of high-quality cutting oil is strongly recommended. The VAP treatment further supports the effect of the cutting oil.

Do you have specific requirements or need advice on choosing the right threading tool? We are happy to help you! You can reach us anytime via our contact form.

Recommended products

57826