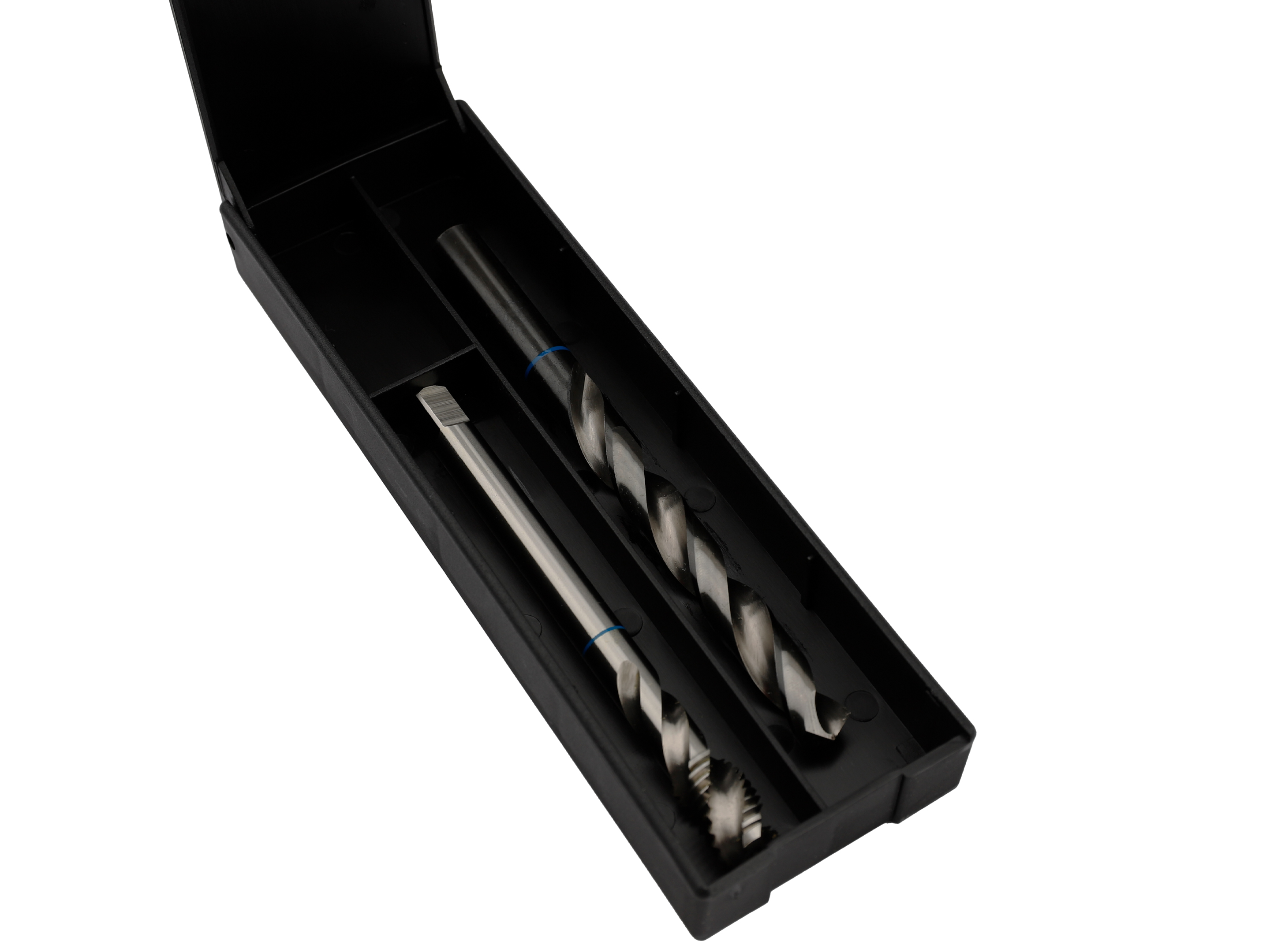

BLUE RING TwinBox Machine Tap + Twist Drill, DIN 376, HSS-E, M 14 x 2.0

€41.70

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

VÖLKEL BLUE RING TwinBox Machine Tap + Twist Drill, DIN 376, HSS-E, M 14 x 2.0

Choose the VÖLKEL BLUE RING TwinBox and master thread cutting in demanding materials with ease. This robust set is specifically designed for creating M14 threads in blind holes and includes the matching twist drill (12 mm). This saves you from searching for the right combination and enables efficient work. The cobalt-alloyed HSS-E steel of the tap ensures a long service life and excellent performance in high-strength steels, while the twist drill provides the exact core hole size according to DIN 13.

Product Details & Specifications

Highlights of this tool set:

- Perfectly matched: The included tools are perfectly coordinated. The 12 mm twist drill bores the ideal core hole for the M14 thread, ensuring a perfect fit.

- High durability: The machine tap made of HSS-E is particularly resistant to heat and wear thanks to its 5% cobalt alloy. It is the first choice for processing alloyed tool steels and stainless steel.

- Optimized for blind holes: The geometry of the tap with its straight flute design and chamfered cutting edge is ideal for blind holes. It allows for reliable chip evacuation to the front and minimizes the risk of tool breakage.

Standards and Tolerances:

- DIN 376: This standard defines the dimensions and tolerances for machine taps with a reinforced shank. This ensures high stability, especially with larger diameters like M14.

- DIN 13: The set is designed for the metric ISO thread according to DIN 13. The designation "M 14 x 2.0" confirms the nominal size and pitch of the thread.

- Tolerance ISO 2 / 6H: This tolerance class ensures a precise internal thread that fits perfectly with most standard metric screws and bolts.

Instructions for use

Use the TwinBox for your project:

- Preparation:

- Insert the 12 mm twist drill into your machine.

- Secure your workpiece firmly to prevent movement.

- Apply sufficient cutting oil to reduce friction and heat.

- Drilling the core hole:

- Drill the hole to the desired depth with a constant, even feed.

- Cutting the thread:

- Switch to the machine tap.

- Begin thread cutting at a low speed and with automatic feed.

- After cutting, carefully pull the tool out and clean the new thread of chips.

This video explains the basic concept of the TwinBox, which applies to all sizes: VÖLKEL BLUE RING TwinBox Video.

This video shows how the TwinBox solves the problem of finding the right twist drill for the tap and how you can access detailed application information by scanning the QR code on the packaging.

Frequently Asked Questions (FAQ)

1. What is the difference between DIN 371 and DIN 376?

DIN 371 refers to machine taps with a reinforced shank for threads up to M10. For larger threads like M14, the DIN 376 standard is used, as it ensures higher stability for the longer tap.

2. Why is the tolerance class ISO 2 / 6H important?

This tolerance guarantees that the thread you cut meets international standards and fits perfectly with other standardized elements. This is crucial for the safety and functionality of the connection.

3. Is the TwinBox also suitable for stainless steel?

Yes, absolutely. The tap is made of HSS-E, a material that was specially developed for tough and high-alloy materials like stainless steel. It is more wear-resistant and retains its cutting edge longer.

4. What is a blind hole?

A blind hole is a hole that does not go completely through a workpiece. The TwinBox, with its special shape, is designed to effectively transport chips out of the hole to the front during cutting, which minimizes the risk of clogging or tool breakage.

5. What happens if I use a drill that is too small?

A core hole that is too small increases the volume of material that the tap has to remove. This can lead to increased resistance, cause the tool to overheat, and, in the worst case, break.

Order now and ensure precise threads!

For more information, please visit our website or contact us via our contact form.

| Type of thread | metric ISO-thread DIN 13 |

|---|---|

| Standard | DIN 376 |

| Form | Form |

| Material | HSS-E |

| Tolerance | ISO 2 /6H |

| Size | Nominal diameter D M 14 x 2.0 |

| EAN | 4022835364979 |

| Item number | 36497 |

VÖLKEL BLUE RING TwinBox Machine Tap + Twist Drill, DIN 376, HSS-E, M 14 x 2.0

Choose the VÖLKEL BLUE RING TwinBox and master thread cutting in demanding materials with ease. This robust set is specifically designed for creating M14 threads in blind holes and includes the matching twist drill (12 mm). This saves you from searching for the right combination and enables efficient work. The cobalt-alloyed HSS-E steel of the tap ensures a long service life and excellent performance in high-strength steels, while the twist drill provides the exact core hole size according to DIN 13.

Product Details & Specifications

Highlights of this tool set:

- Perfectly matched: The included tools are perfectly coordinated. The 12 mm twist drill bores the ideal core hole for the M14 thread, ensuring a perfect fit.

- High durability: The machine tap made of HSS-E is particularly resistant to heat and wear thanks to its 5% cobalt alloy. It is the first choice for processing alloyed tool steels and stainless steel.

- Optimized for blind holes: The geometry of the tap with its straight flute design and chamfered cutting edge is ideal for blind holes. It allows for reliable chip evacuation to the front and minimizes the risk of tool breakage.

Standards and Tolerances:

- DIN 376: This standard defines the dimensions and tolerances for machine taps with a reinforced shank. This ensures high stability, especially with larger diameters like M14.

- DIN 13: The set is designed for the metric ISO thread according to DIN 13. The designation "M 14 x 2.0" confirms the nominal size and pitch of the thread.

- Tolerance ISO 2 / 6H: This tolerance class ensures a precise internal thread that fits perfectly with most standard metric screws and bolts.

Instructions for use

Use the TwinBox for your project:

- Preparation:

- Insert the 12 mm twist drill into your machine.

- Secure your workpiece firmly to prevent movement.

- Apply sufficient cutting oil to reduce friction and heat.

- Drilling the core hole:

- Drill the hole to the desired depth with a constant, even feed.

- Cutting the thread:

- Switch to the machine tap.

- Begin thread cutting at a low speed and with automatic feed.

- After cutting, carefully pull the tool out and clean the new thread of chips.

This video explains the basic concept of the TwinBox, which applies to all sizes: VÖLKEL BLUE RING TwinBox Video.

This video shows how the TwinBox solves the problem of finding the right twist drill for the tap and how you can access detailed application information by scanning the QR code on the packaging.

Frequently Asked Questions (FAQ)

1. What is the difference between DIN 371 and DIN 376?

DIN 371 refers to machine taps with a reinforced shank for threads up to M10. For larger threads like M14, the DIN 376 standard is used, as it ensures higher stability for the longer tap.

2. Why is the tolerance class ISO 2 / 6H important?

This tolerance guarantees that the thread you cut meets international standards and fits perfectly with other standardized elements. This is crucial for the safety and functionality of the connection.

3. Is the TwinBox also suitable for stainless steel?

Yes, absolutely. The tap is made of HSS-E, a material that was specially developed for tough and high-alloy materials like stainless steel. It is more wear-resistant and retains its cutting edge longer.

4. What is a blind hole?

A blind hole is a hole that does not go completely through a workpiece. The TwinBox, with its special shape, is designed to effectively transport chips out of the hole to the front during cutting, which minimizes the risk of clogging or tool breakage.

5. What happens if I use a drill that is too small?

A core hole that is too small increases the volume of material that the tap has to remove. This can lead to increased resistance, cause the tool to overheat, and, in the worst case, break.

Order now and ensure precise threads!

For more information, please visit our website or contact us via our contact form.

Recommended products

Empfohlene Produkte