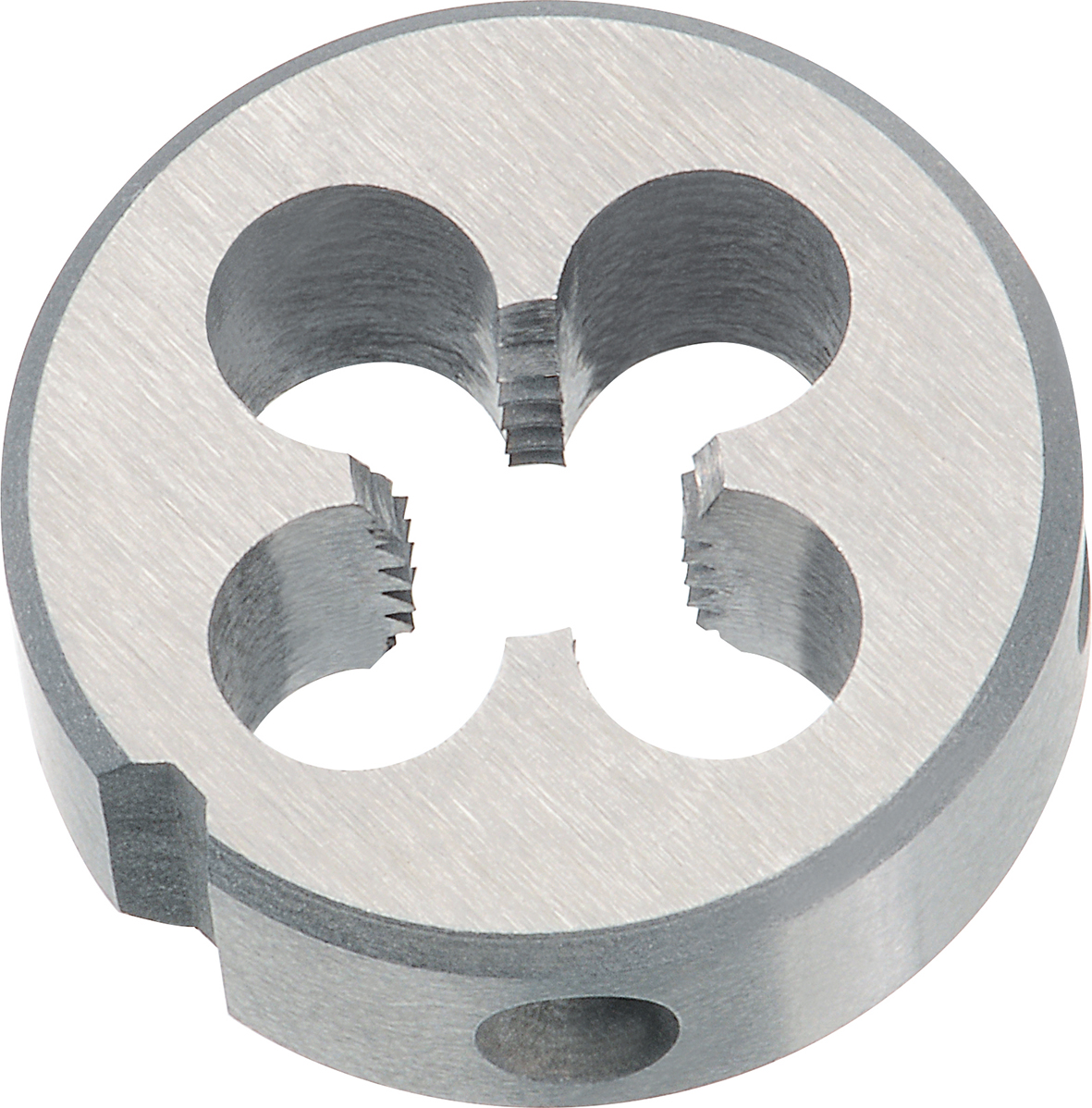

Angler's Thread Set, Short Machine Tap + Round Die, BSF 3/8 x 20

€19.80

VÖLKEL delivers exclusively to specialized dealers. Online you can buy VÖLKEL products here.

The prices are in Euro plus VAT and shipping, insurance and packaging costs.

Angler's Thread Set, Short Machine Tap + Round Die, BSF 3/8 x 20

Use this die for external thread cutting when you need controlled engagement and straight tracking. Die alignment at the start determines straightness and flank engagement.

Select the correct thread designation and ensure that the pre hole and chamfer preparation match the tool and material. BSF indicates a Whitworth form inch thread with a finer series, common in maintenance and retrofit work.

Application

- Cut new external threads or restore damaged external threads on bolts and studs.

- Use in service workshops and plant maintenance for fitting work on threaded shafts.

- Keep the die aligned and lubricated for stable engagement and surface quality.

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

Note For consistent results, deburr the entry and keep the cutting area clean during use.

Benefits

- Allows controlled external thread cutting on prepared diameters

- Useful for restoring damaged threads without part replacement

- Simple setup for repair work and low volume manufacturing

- Works with standard holders and wrenches for workshop use

- External thread quality depends strongly on alignment and workpiece preparation.

- Not intended for high performance CNC threading where dedicated tooling is required.

Step by step

- Prepare the workpiece diameter and add a small lead in chamfer.

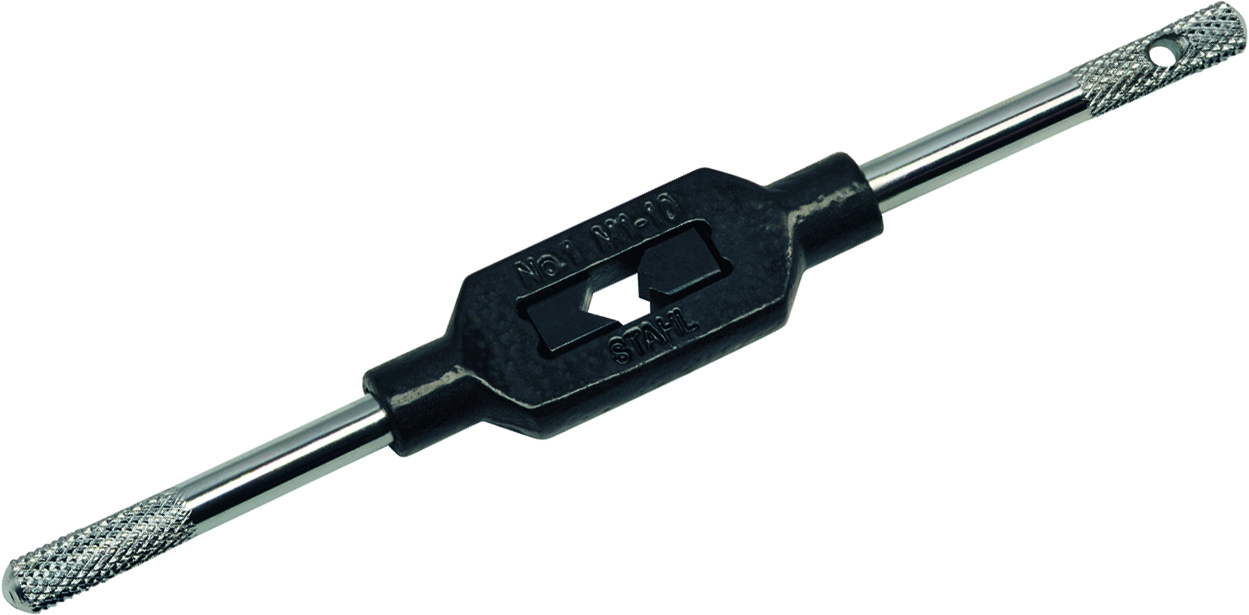

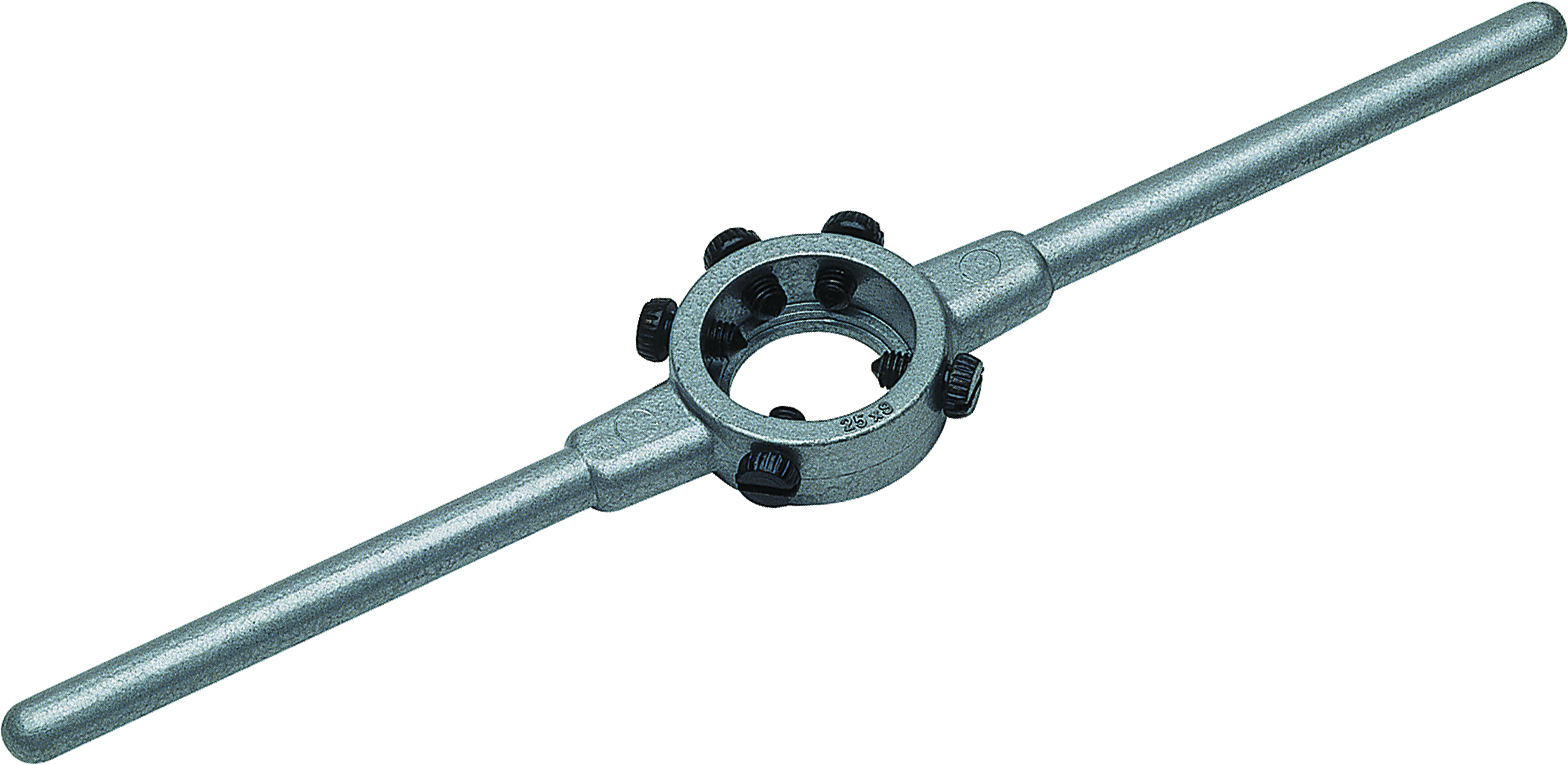

- Mount the die in a suitable holder and ensure it seats flat.

- Apply lubricant appropriate for the material and thread form.

- Start the die square to the axis and apply steady torque.

- Advance gradually while monitoring alignment and surface feel.

- Remove the die at intervals to clear chips from the cutting edges.

- Finish to the required thread length and deburr the thread start.

Scope of supply

- 1 set Angler's Thread Set, Short Machine Tap + Round Die, BSF 3/8 x 20

Technical features

- Tool type: Threading die for external threads

- Thread system: BSF

Frequently asked questions (FAQ)

- How do you confirm that the thread system matches the mating part?

- Match the designation on the tool to the drawing and the mating fastener or gauge. For inch and pipe threads, confirm thread family and fit class before you start machining.

- How do you avoid a crossed start on external threads?

- Start square to the axis and keep the die face flat on the chamfer. If it feels tilted, stop and reset rather than forcing the first turns.

- Where can you find technical information for short machine taps?

- Use this document for selection and process reliability notes. Technical information short machine taps as PDF

- What are common causes of poor thread quality?

- Misalignment at the start, an incorrect pre hole, or insufficient lubrication can increase torque and damage flanks. Clean chips from the tool and verify setup rigidity.

- Where can you find additional technical information for this tool type?

- Use this document for further selection and application notes. Technical information machine taps as PDF

- Can you use this tool for reworking an existing thread?

- You can often re tap or clean threads if the original form is correct and damage is limited. If threads are severely deformed, consider re machining or repair options instead.

- How do you keep the process stable across parts?

- Keep handling and lubrication consistent and verify alignment at the start. Clean the tool and the thread between checks so feel stays comparable.

- Where can you find catalog information for this product family?

- Use the product catalog for overview tables and selection context. VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.

Angler's Thread Set, Short Machine Tap + Round Die, BSF 3/8 x 20

Use this die for external thread cutting when you need controlled engagement and straight tracking. Die alignment at the start determines straightness and flank engagement.

Select the correct thread designation and ensure that the pre hole and chamfer preparation match the tool and material. BSF indicates a Whitworth form inch thread with a finer series, common in maintenance and retrofit work.

Application

- Cut new external threads or restore damaged external threads on bolts and studs.

- Use in service workshops and plant maintenance for fitting work on threaded shafts.

- Keep the die aligned and lubricated for stable engagement and surface quality.

- Process: manual driving or assisted driving depending on your holder and machine setup

- Use: thread cutting, re tapping, and thread cleaning depending on condition

Note For consistent results, deburr the entry and keep the cutting area clean during use.

Benefits

- Allows controlled external thread cutting on prepared diameters

- Useful for restoring damaged threads without part replacement

- Simple setup for repair work and low volume manufacturing

- Works with standard holders and wrenches for workshop use

- External thread quality depends strongly on alignment and workpiece preparation.

- Not intended for high performance CNC threading where dedicated tooling is required.

Step by step

- Prepare the workpiece diameter and add a small lead in chamfer.

- Mount the die in a suitable holder and ensure it seats flat.

- Apply lubricant appropriate for the material and thread form.

- Start the die square to the axis and apply steady torque.

- Advance gradually while monitoring alignment and surface feel.

- Remove the die at intervals to clear chips from the cutting edges.

- Finish to the required thread length and deburr the thread start.

Scope of supply

- 1 set Angler's Thread Set, Short Machine Tap + Round Die, BSF 3/8 x 20

Technical features

- Tool type: Threading die for external threads

- Thread system: BSF

Frequently asked questions (FAQ)

- How do you confirm that the thread system matches the mating part?

- Match the designation on the tool to the drawing and the mating fastener or gauge. For inch and pipe threads, confirm thread family and fit class before you start machining.

- How do you avoid a crossed start on external threads?

- Start square to the axis and keep the die face flat on the chamfer. If it feels tilted, stop and reset rather than forcing the first turns.

- Where can you find technical information for short machine taps?

- Use this document for selection and process reliability notes. Technical information short machine taps as PDF

- What are common causes of poor thread quality?

- Misalignment at the start, an incorrect pre hole, or insufficient lubrication can increase torque and damage flanks. Clean chips from the tool and verify setup rigidity.

- Where can you find additional technical information for this tool type?

- Use this document for further selection and application notes. Technical information machine taps as PDF

- Can you use this tool for reworking an existing thread?

- You can often re tap or clean threads if the original form is correct and damage is limited. If threads are severely deformed, consider re machining or repair options instead.

- How do you keep the process stable across parts?

- Keep handling and lubrication consistent and verify alignment at the start. Clean the tool and the thread between checks so feel stays comparable.

- Where can you find catalog information for this product family?

- Use the product catalog for overview tables and selection context. VD 23 catalog as PDF

Do you need help selecting or using the product?

Use the contact form.

Recommended products

Related products