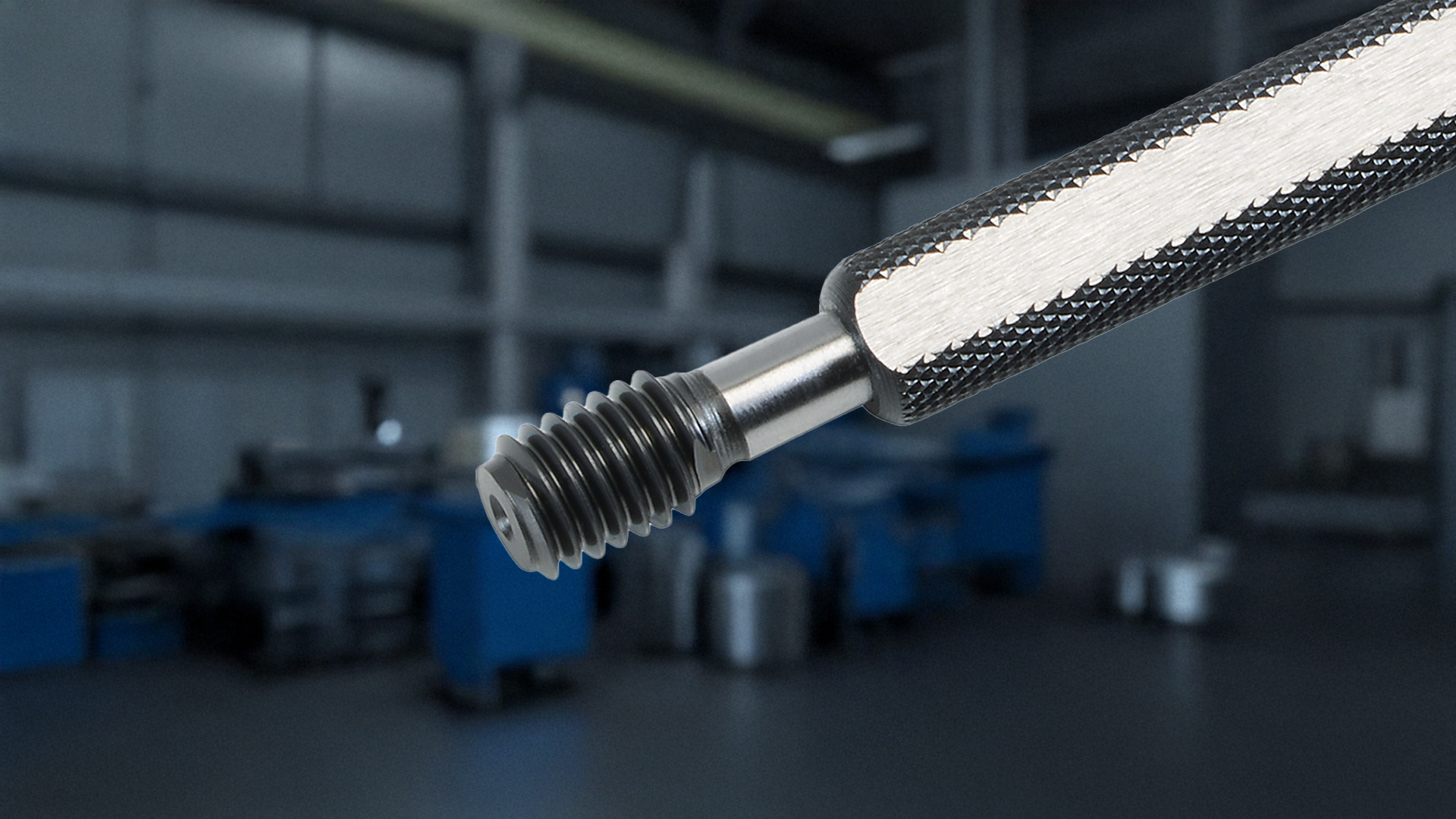

Coatings for Threading Tools: Maximize Performance

Basics & benefits of surface treatments

When it comes to the efficiency and service life of your threading tools, every detail counts. Surface treatments and coatings play a central role in maximizing tool performance, reducing wear, and achieving optimal cutting results.

In this article, you'll learn about the different processes, how they work, and the specific advantages they offer you.

Why surface treatments are essential for threading tools

- Increase surface hardness

- Enhance wear resistance

- Improve sliding properties

- Prevent cold welding

- Enable higher cutting speeds

Detailed overview of processes

Vaporizing (VAP) – For better lubricant adhesion

In this thermal treatment, an iron oxide layer forms on the tool's surface, improving lubrication and reducing the risk of cold welding.

- Better lubricant retention

- Longer tool life

- Reduced friction

Nitriding (NIT) – For maximum surface hardness

This process enriches the surface with nitrogen, significantly increasing hardness. Ideal for tools used on cast iron and similar materials.

- Higher abrasion resistance

- Improved sliding behavior

- Reduced cold welding tendency

TiN (Titanium Nitride) – The proven all-rounder

A golden coating applied via PVD. It offers high hardness and excellent wear resistance across a wide range of applications.

- Good thermal stability

- High chemical resistance

- Versatile usage

- Allows higher cutting speeds

TiCN (Titanium Carbonitride) – For tougher materials

Harder than TiN with lower friction, especially effective against steel and abrasive materials.

- Extremely high wear resistance (~3,000 HV)

- Good heat dissipation

- Ideal for hard materials

TiAlN (Titanium Aluminum Nitride) – For extreme heat

Optimized for dry machining and high-speed applications with outstanding hardness and heat resistance.

- Maximum abrasion resistance

- Longer tool life

- Excellent for dry cutting

CrN (Chromium Nitride) – For non-ferrous metals

This silver-metallic coating is ideal for materials like aluminum or copper due to its excellent adhesion and anti-stick effect.

- Corrosion-resistant

- High elasticity

- Strong anti-adhesion effect

Comparison Table: Coatings & Surface Treatments

| Process / Coating | Color | Hardness (HV) | Temp. Resistance | Friction / Sliding | Key Advantages | Recommended For |

|---|---|---|---|---|---|---|

| Vaporizing (VAP) | Dark gray / bluish | – | Medium | Good | Improved lubrication, reduced cold welding | General use, steel machining |

| Nitriding (NIT) | – | High | Medium | Good | High surface hardness, abrasion resistance | Cast iron, low alloy steels |

| TiN | Gold | ~2,600 | Up to 600 °C | Good | Universal, fast cutting | Steel, non-ferrous metals |

| TiCN | Gray-violet | ~3,000 | Up to 400–450 °C | Very good | Highly wear-resistant, low friction | Hard steels, abrasives |

| TiAlN | Black-violet | ~3,300 | Up to 800–900 °C | Very good | Top heat resistance, dry machining | High alloy steels |

| CrN | Silver-metallic | ~1,800–2,000 | Medium | Excellent with non-ferrous metals | Corrosion protection, anti-adhesion | Aluminum, copper, non-ferrous metals |

The right coating makes the difference

Choosing the right surface treatment or coating is key to extending tool life and ensuring top performance. Whether it’s TiN, TiCN, TiAlN or vaporizing – Voelkel offers the perfect solution for your needs.

Want to know which coating suits your application best?

Contact us – we’ll be happy to advise you personally.