Since this year, VÖLKEL has been supporting the HyEnD student team from the University of Stuttgart in developing their hybrid rocket. The project places extreme demands on every single component – especially on the connections. To ensure that the structure remains reliable even under high loads, the team relies on V-COIL thread inserts.

Technical Challenge: Secure Structural Connection of the Engine

The machined component takes on several key functions within the HyEnD project:

It connects the engine with the rocket’s outer shell.

It also forms the upper part of the injector distributor through which the fuel mixture is fed.

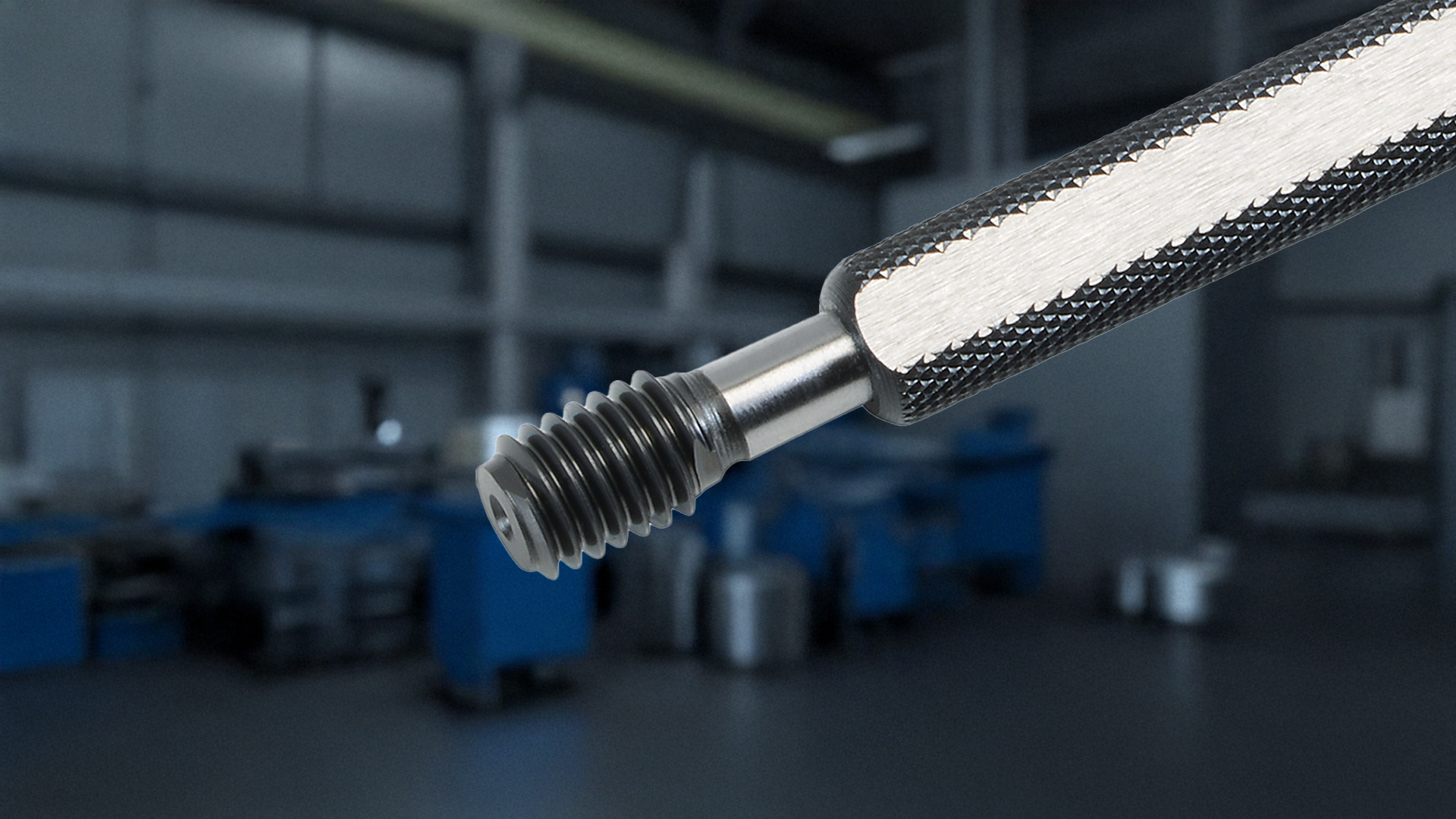

The component is made from aluminum 7075 – a high-strength yet lightweight material ideal for aerospace applications.

The machining ratio is around 95%, meaning maximum precision with minimal material tolerance.

The connection transmits thrust forces of up to 15 kN – a load that allows no margin for error.

To safely handle these forces, the team uses stainless-steel M5 V-COIL thread inserts. They reinforce the threads in the aluminum component, raising the joint’s strength to the level of stainless steel.

Why Thread Inserts Are Indispensable

In lightweight metals such as aluminum, conventional threads offer only limited strength. Under high loads, threads can strip or loosen – especially with repeated tightening or strong vibrations. This is where V-COIL thread inserts come into play, ensuring a durable and reliable thread even under extreme conditions.

1. Reinforcement of the Base Material

A thread insert distributes forces across a much larger surface. The stainless-steel thread effectively strengthens the soft aluminum, resulting in higher pull-out and shear strength, longer service life, and even load distribution. Studies and manufacturer data confirm that thread inserts significantly extend the lifespan of threaded joints in light metals.

2. Resistance to Vibration and Temperature Changes

In aerospace applications, strong vibrations, alternating loads, and temperature fluctuations occur. Thread inserts prevent loosening or damage of the connection. The internal thread remains stable, even after multiple assemblies or retightening.

3. Precision and Cost Efficiency

Beyond their technical advantages, thread inserts offer economic benefits. They can repair damaged threads or reinforce existing holes without the need to remake the entire component. For highly precise aluminum components, as used in the HyEnD project, this is a decisive advantage.

Implementation in the HyEnD Project

Thread reinforcement was directly integrated into the design:

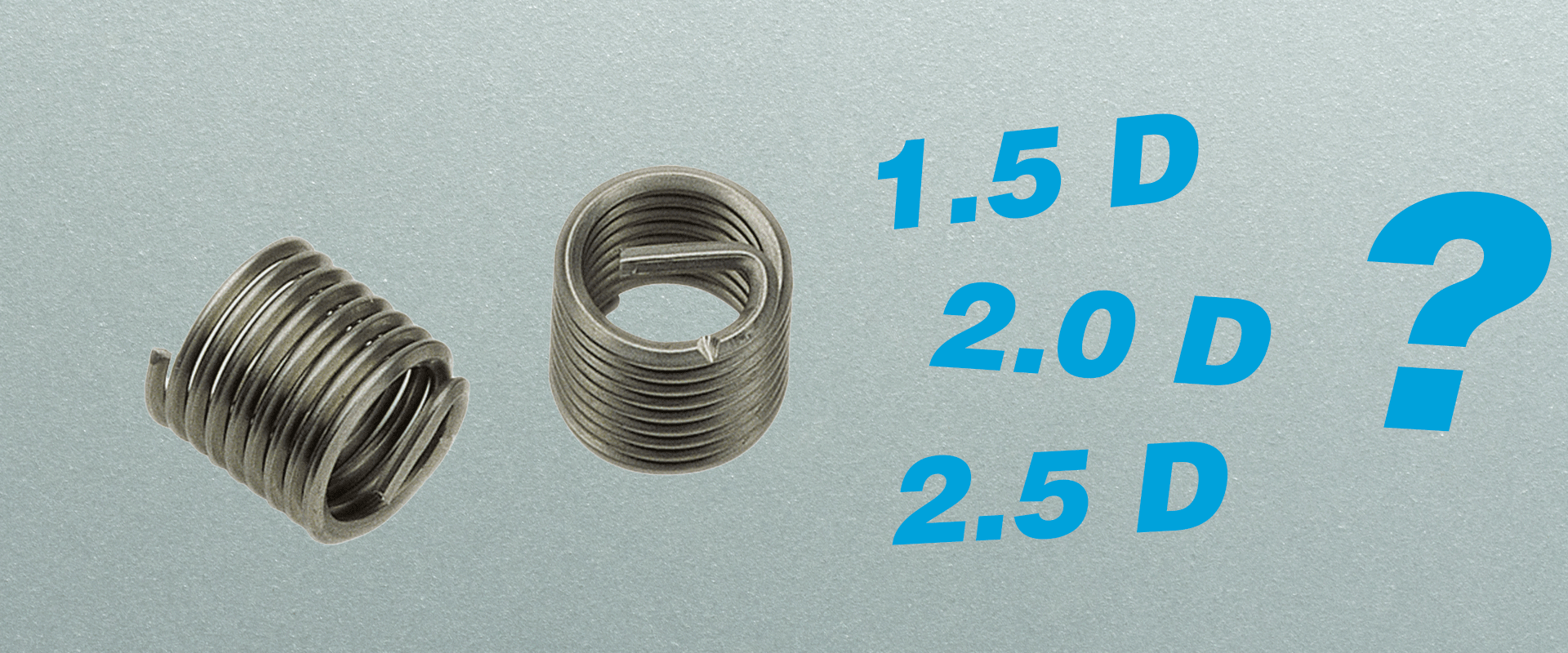

The threads in the aluminum structure were equipped with V-COIL M5 inserts.

Thanks to the stainless-steel coils, the thread achieves the tensile strength of stainless steel – significantly higher than that of the base material.

The installation area is located at the interface between the engine and outer structure – precisely where the thrust forces are introduced.

Each insert ensures maximum durability, prevents thread stripping, and enables precise, repeatable assembly.

Proven Technology – Even for Extreme Applications

What works in rocket engineering also proves its value in other industries. Thread inserts are used wherever lightweight materials must withstand high forces – from mechanical and automotive engineering to aerospace. They offer a permanent, repeatable solution where precision and reliability matter.

The HyEnD example demonstrates impressively that V-COIL thread inserts are not only designed for everyday industrial applications but also for extreme conditions.

About V-COIL

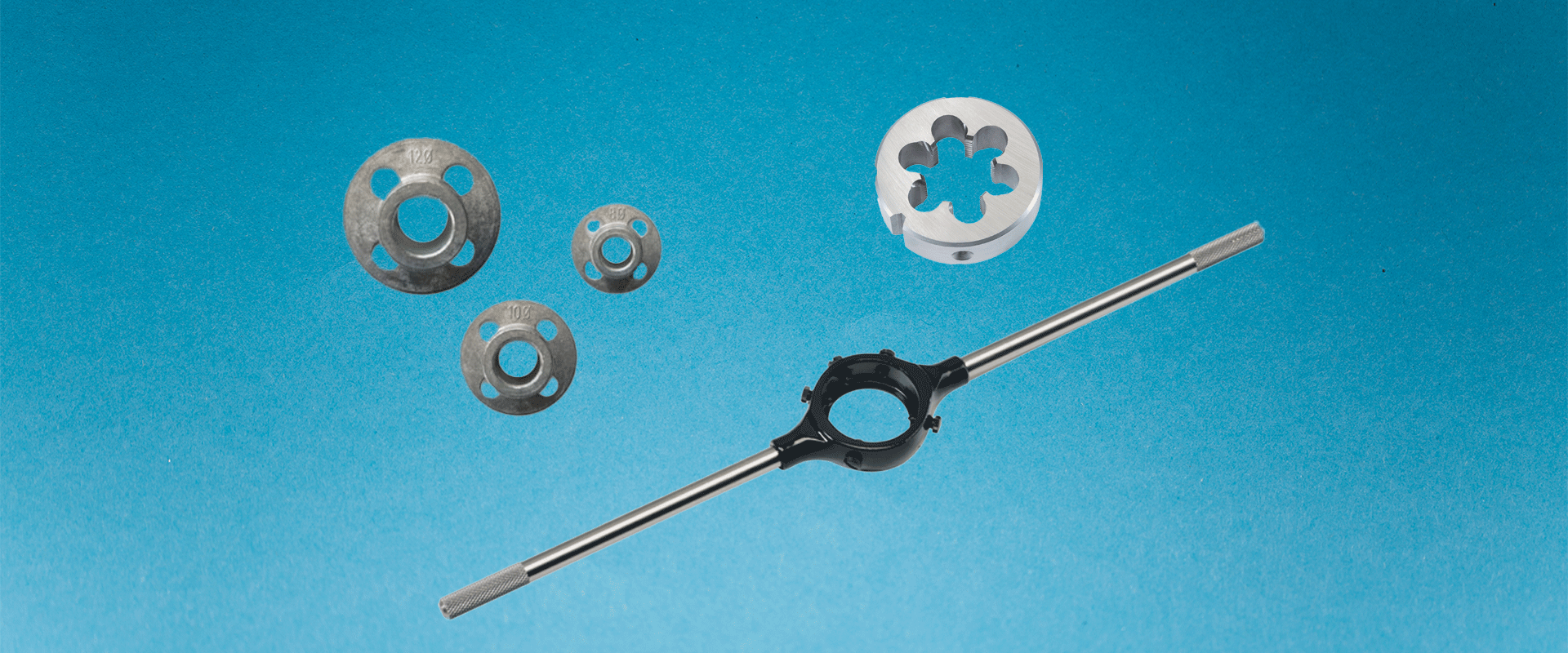

V-COIL is a system of thread inserts developed to permanently reinforce, repair, or protect threads from wear. The inserts are made from high-quality stainless steel and are used in a wide range of industries – from mechanical engineering and electrical technology to aerospace.

The principle is simple yet effective: a V-COIL thread insert is installed into a pre-drilled and tapped hole, forming a precise, wear-resistant internal thread. This greatly increases the load capacity of the connection – especially in lightweight materials such as aluminum, magnesium, or plastics.

With decades of experience in thread technology, VÖLKEL stands for quality, precision, and reliability. Our V-COIL systems are in use worldwide, proving themselves wherever strong and long-lasting threads are required.