Thread Forming: Chip-free, Clean, Reliable

Introduction: Why produce threads without chips?

Anyone who manufactures internal threads knows the basic problem: chips. They must be reliably removed, they can get stuck, they block tools, and they cause trouble exactly when space is tight, for example, in blind holes, during automated processes, or in series production.

In sensitive production environments, an additional point arises. Chips simply have no place there, such as in the manufacturing of electronic components or in facilities that come into contact with food. Any contamination can pose a real risk here.

There is a process that avoids many of these difficulties from the outset: thread forming. These tools are also called thread formers or thread rolling taps. Completely chip-free, with high process stability and a stable thread as a result. In the video below, you can see what the process looks like on the machine and what is important.

What is Thread Forming?

In thread forming, the internal thread is created not by material removal, but by material displacement. The process is based on cold forming. The material flows into the thread profile, nothing is cut, and the material remains in the component.

This is the biggest difference to classic thread cutting.

Cutting tools remove material and create chips.

Forming tools compact and deform the material.

Typical applications are deformable materials such as many steels, aluminum alloys, brass, or copper materials. In these materials, the thread former consistently exploits its advantages.

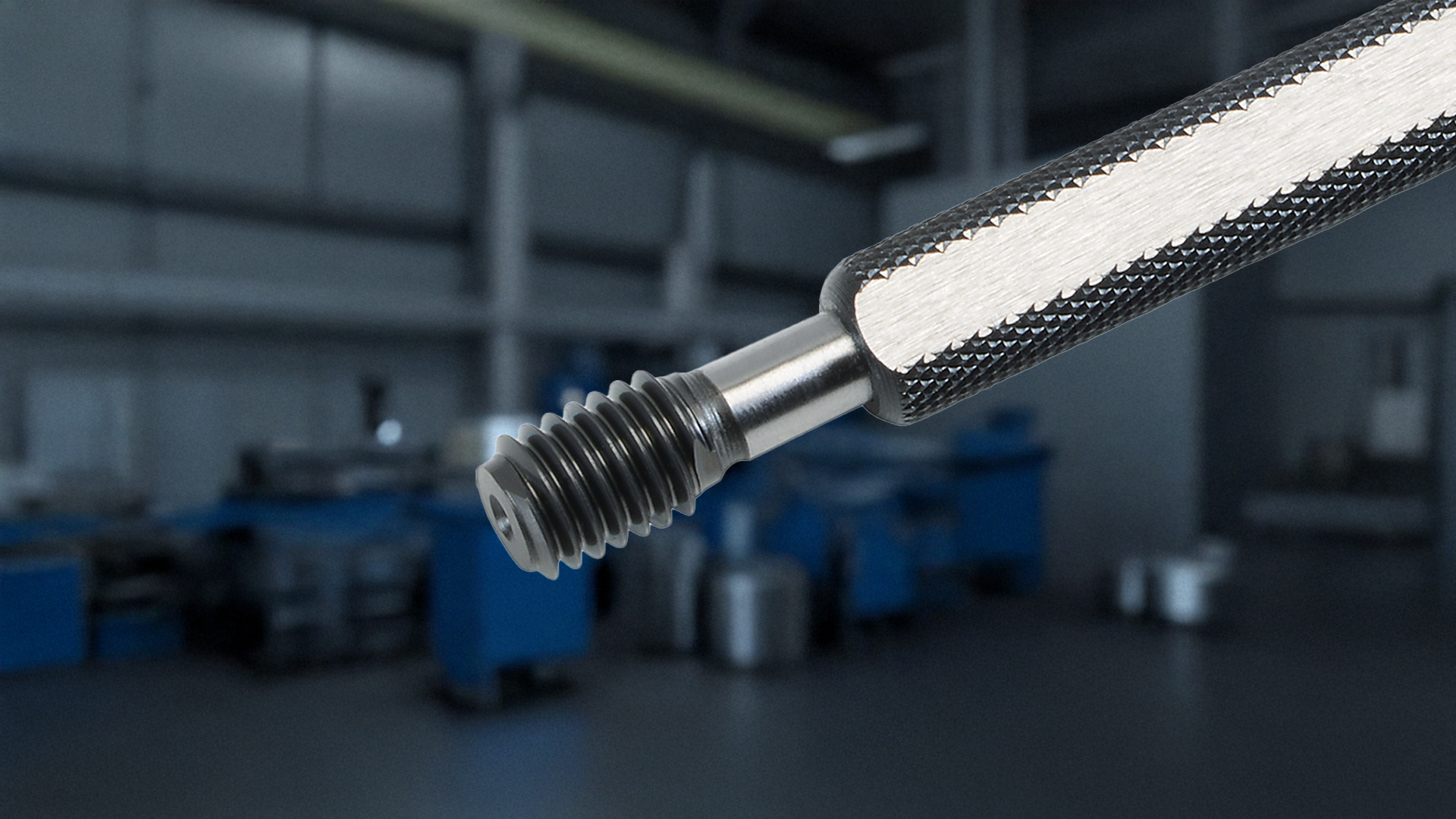

Tool Geometry: How the thread former differs from the tap

A tap (thread cutter) has cutting edges and flutes that evacuate the resulting chips.

A thread former, however, has no flutes. Instead, it is slightly polygonal in shape and presses the thread profile into the material.

This geometry makes the tool more solid and less susceptible to fracture loads. The edges are not worn down by cutting-related wear, which later becomes noticeable in the tool life.

In the embedded video, we show exactly these differences with two component views – one tap, one thread former.

Core Hole Diameter in Thread Forming - Why the core hole diameter must be larger

In thread forming, the material flows into the profile. Therefore, the core hole must be larger than in cutting. A diameter that is too small leads to over-forming, high torque, and, in the worst case, tool breakage or a dimensionally unstable thread.

An example from the video:

M8 Thread Forming: 7.45 mm

M8 Thread Cutting: 6.8 mm

The difference seems small but is crucial for the result. Those who work with core holes that are too small create problems long before the thread is even finished.

Material and Grain Flow: Why the thread becomes stronger

When cutting, the grain flow (microstructure) is severed. The microstructure in the material loses its continuity, and the cutting edges create notches that can later affect the load-bearing capacity.

The opposite happens during thread forming. The grain structure is deformed, not separated. A densified, continuous grain flow is created, which makes the thread more stable and reduces notch sensitivity.

Advantages and Disadvantages of Thread Forming

Advantages

No Chips Without chips, there is no risk of chip congestion, no crater formation in blind holes, and no additional effort for chip evacuation. The component remains clean, which is a real advantage, especially in automated systems and series processes. In manufacturing environments that demand absolute cleanliness – for example, in electronic assemblies or food-related processes – even a single chip can lead to rejects. Working chip-free prevents exactly that.

Longer Tool Life and Higher Thread Strength The material is cold-hardened and not cut. This ensures robust threads and long tool life because no cutting edges wear out.

Process Stability and Good Automation Capabilities Thread forming delivers reproducible results and runs very reliably in modern CNC environments. This is a clear advantage for series production.

Better Surface Quality in the Thread The surface of the formed thread is smoother and denser because no cutting notches are created. This improves the load-bearing capacity, and screws start more easily.

Disadvantages / Limitations

Higher Torques Required Thread forming requires about 40–50% more torque than cutting. The machine must have this power reserve, otherwise the process cannot be used reliably.

Material Dependence: Cold Formability is Mandatory Only ductile, formable materials are suitable for this. Very hard or brittle materials lead to cracks, dimensional problems, or tool damage.

Stricter Requirements for Bore, Lubrication, and Parameters Core hole diameter, lubricant, and process parameters must fit exactly. Incorrect core holes or a lack of lubrication threaten tool breakage and faulty threads.

When is Thread Forming Worthwhile?

Recommended when:

the material is easily formable (ductile)

the machine provides sufficient torque

the process must be automated or particularly clean

high thread strength or smooth thread surfaces are required

chips would be problematic (blind holes, cleanrooms, electronics, food)

Less suitable when:

material is too hard or brittle

too little torque is available

tight bore tolerances cannot be reliably maintained

VÖLKEL Thread Formers in Practice

VÖLKEL offers forming tools designed for reliable and reproducible results that can be easily integrated into existing manufacturing processes.

Upon request, the formers are also available with a lubrication groove. This groove improves the lubricant distribution during engagement, reduces friction, and thus supports both dimensional accuracy and tool life – especially in more demanding materials.

Additionally, VÖLKEL also offers formers with an oversize. This variant is useful if components later receive a galvanic protective layer. The layer builds up and narrows the thread. An oversize former compensates for this and ensures that the thread remains dimensionally accurate after coating.

For even better performance, we also offer the formers with various surface treatments and coatings. These reduce friction values, improve running behavior, and stabilize the process under higher loads.

All relevant tables for core hole diameters, application parameters, and available variants can be found online and in our catalog.

Conclusion

Thread forming has long established itself in practice as a reliable process, especially where chips are disruptive or high process stability is required. Chip-free, with stable threads and very good tool life, it is the better choice for many applications.