Thread Cutting Tool Set for Grease Nipples

Longer service life, less hassle: getting grease nipple threads back in shape

Whether a lubrication point works reliably often comes down to a small detail that is easy to overlook in everyday maintenance: the thread in the grease nipple port. Grease nipples ensure lubricant is delivered precisely to bearings, joints and guides. For that to work, the nipple must seat tightly, engage cleanly and screw in without excessive force.

In practice, thread problems often only become obvious once they start causing frustration: the grease nipple cants as you start it, no longer sits securely, or cannot be installed at all. Then lubricant either leaks out or does not reach the lubrication point reliably. Both can lead to consequential damage, from increased wear to the failure of bearings or joints. That’s exactly why it’s worth treating grease nipple threads not as a minor issue, but as a fixed part of maintenance and servicing routines.

What is a thread cutting tool set for grease nipples, and how does it work?

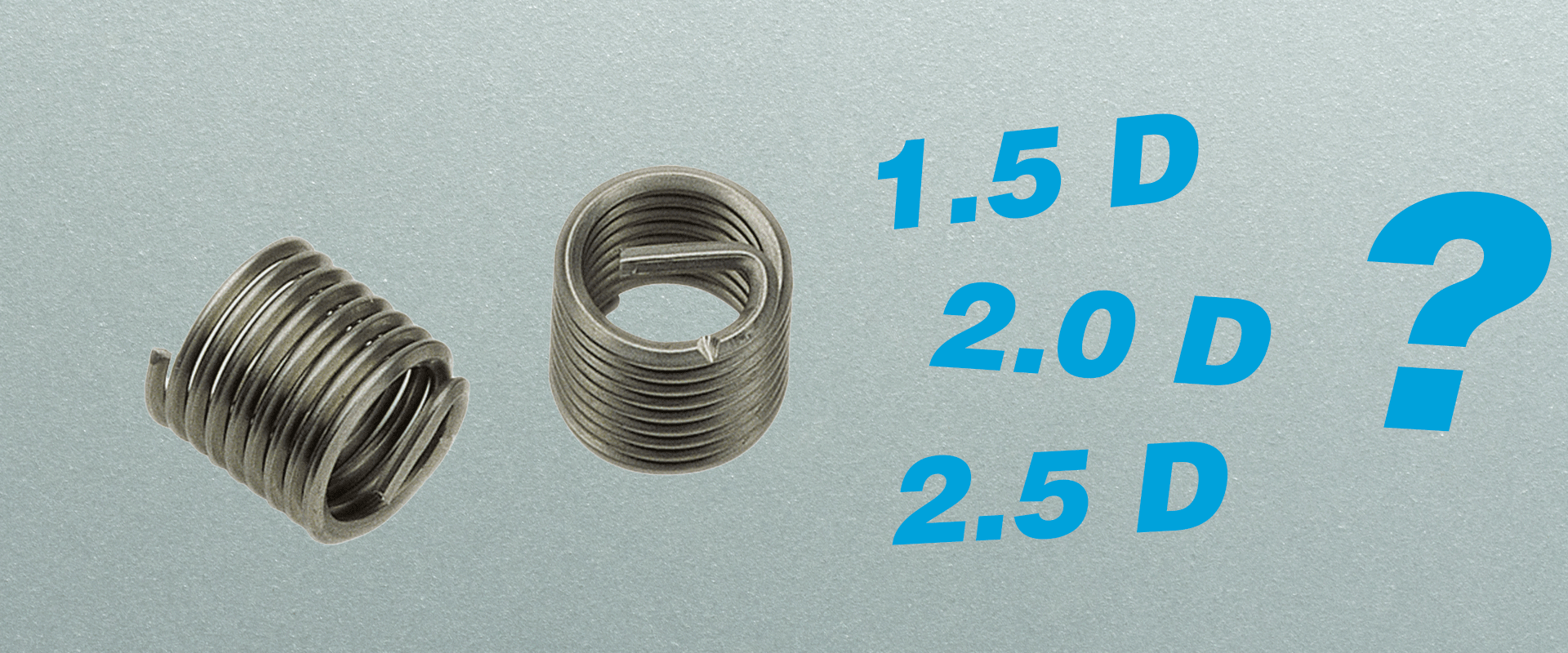

A thread cutting tool set for grease nipples is a set of taps matched to the common thread sizes found in grease nipple ports. In most cases the goal is not to cut completely new threads, but what is far more common: re-tapping and cleaning existing internal threads.

Re-tapping removes deposits, old grease residues, dirt and minor damage from the thread flanks. This restores clean guidance and load-bearing thread engagement. Afterwards, the grease nipple can be screwed in straight again, sits firmly and seals reliably. Especially in maintenance and repair work, this is a fast way to make a lubrication point operational again without unnecessary rework.

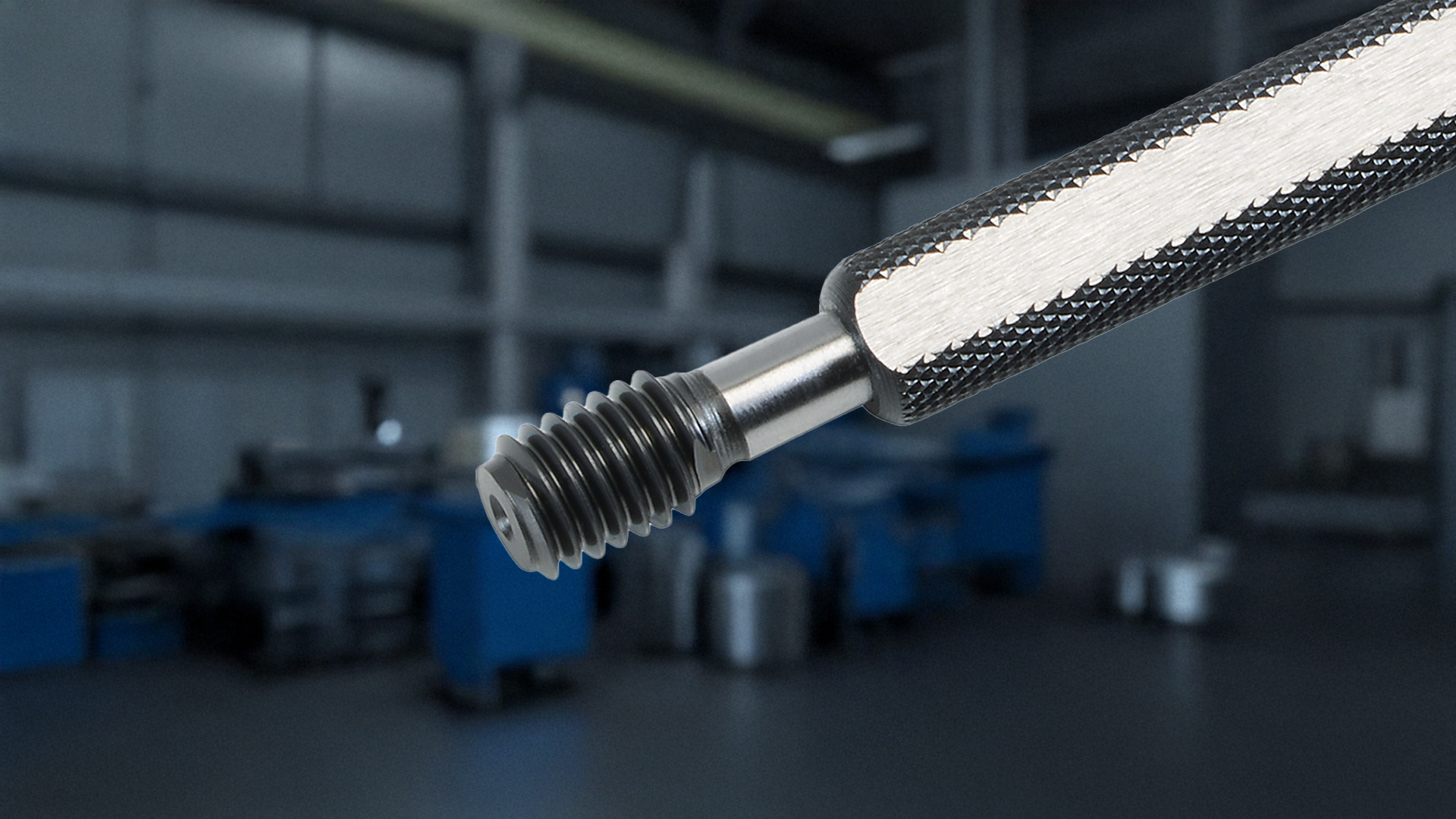

Our taps in the set are made of HSS-G, i.e. ground high-speed steel. This provides precise cutting geometry, clean thread profiles and good tool life in everyday workshop use. Particularly when threads run tight due to corrosion or contamination, this makes the difference: controlled work, a clean result and less risk of further damaging the thread during reconditioning.

Where is the set used, and why is it so relevant?

You’ll find grease nipples wherever moving parts need lubrication: in mechanical engineering, agriculture, commercial vehicles, workshops and industrial maintenance. The thread is not just a means of fastening—it is a functional guarantee. It ensures correct positioning, secure hold and sealing.

If this thread is damaged or clogged, lubrication becomes unreliable. That’s not just a convenience issue—it can directly affect component service life. Anyone looking to avoid downtime and consequential costs needs a solution that is quickly available and proven in real-world use.

Typical challenges with grease nipple threads

In daily use, we most often see these causes:

Contamination. Grease, wear particles and dirt build up in the thread grooves. The grease nipple then engages poorly or cants.

Corrosion. Moisture and aggressive environments attack the thread flanks. The thread becomes tight-running or damaged.

Mechanical stress. Vibration, impacts or starting the nipple at an angle can deform the thread grooves.

Different thread systems. Depending on the machine, metric threads and BSPP (G) pipe threads may be used side by side. Without the right tools, this costs time and increases the risk of incorrect use.

The solution: the VÖLKEL thread cutting tool set for grease nipples

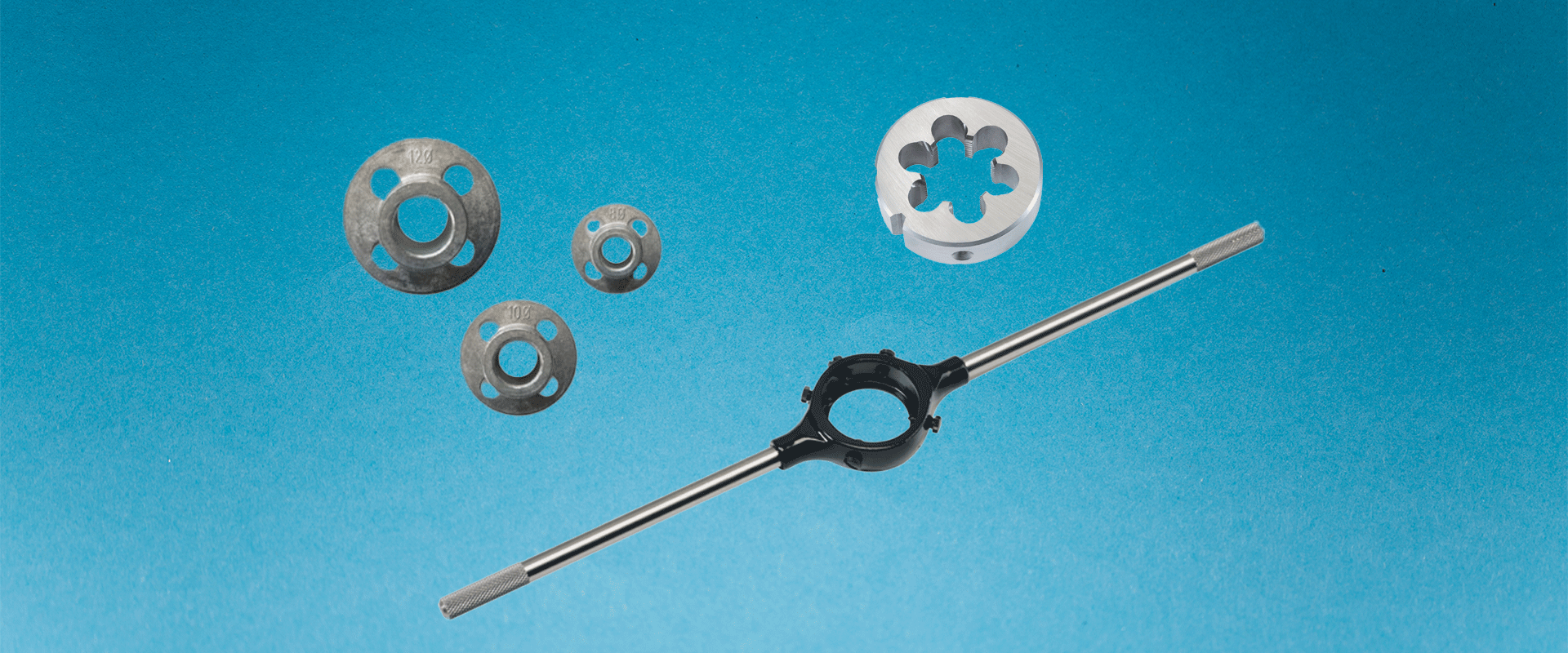

This is exactly why we put together the VÖLKEL thread cutting tool set for grease nipples. It covers the common thread types most frequently found in grease nipple ports—both metric ISO threads and BSPP (G) pipe threads.

The set includes six practical, workshop-relevant sizes:

M 6 x 1.0

M 8 x 1.0

M 10 x 1.0

M 10 x 1.25

G 1/8 x 28

G 1/4 x 19

All taps are neatly organized in a durable plastic case with foam insert. This protects the tools, keeps everything clearly arranged and also makes the set attractive for mobile use. And if you need one size especially often, we can of course supply individual taps as replacements. That’s how we at VÖLKEL define a solution that doesn’t just work once, but fits reliably into your process long term.

Workshop use: fast, controlled, practical

The handling is intentionally straightforward—because it has to work in everyday conditions. Determine the correct size, remove the grease nipple, clean the port. Then start the tap straight and re-cut evenly using cutting oil. Remove chips, check the thread, reinstall the grease nipple. In many cases, the lubrication point is immediately ready for use again.

Available from stock for immediate delivery

When a lubrication point doesn’t work, time matters. With the VÖLKEL thread cutting tool set for grease nipples, you have a set on hand that solves typical thread issues quickly and reduces unnecessary consequential damage. The set is available from stock for immediate delivery and can be used directly in workshops, service and maintenance operations.

Conclusion

An intact grease nipple thread is the basis for reliable lubrication. Contamination, corrosion and mechanical stress are part of everyday reality—but with the right tools, the job can be handled quickly and cleanly. With the VÖLKEL thread cutting tool set for grease nipples, we offer a practical solution featuring HSS-G quality, the key sizes and robust storage. It shows what VÖLKEL Threading Solutions stands for: threading tools and technology that work reliably in real-world use.