Length of thread inserts: What “1.5 D” means - simply explained!

In metalworking, threading tools are among the most important precision tools. This also includes thread repair tools. Especially when it comes to thread repairs, users often ask themselves: What do the length specifications like “1.5xD” mean for thread inserts? This seemingly simple designation holds important technical details that are crucial for successful application.

VÖLKEL Threading Solutions offers V-COIL thread inserts in various standardized lengths. Selecting the correct insert length is essential not only for functionality but also for the durability of the thread repair. In this article, we explain the meaning behind the length specifications and what you should pay attention to when choosing them.

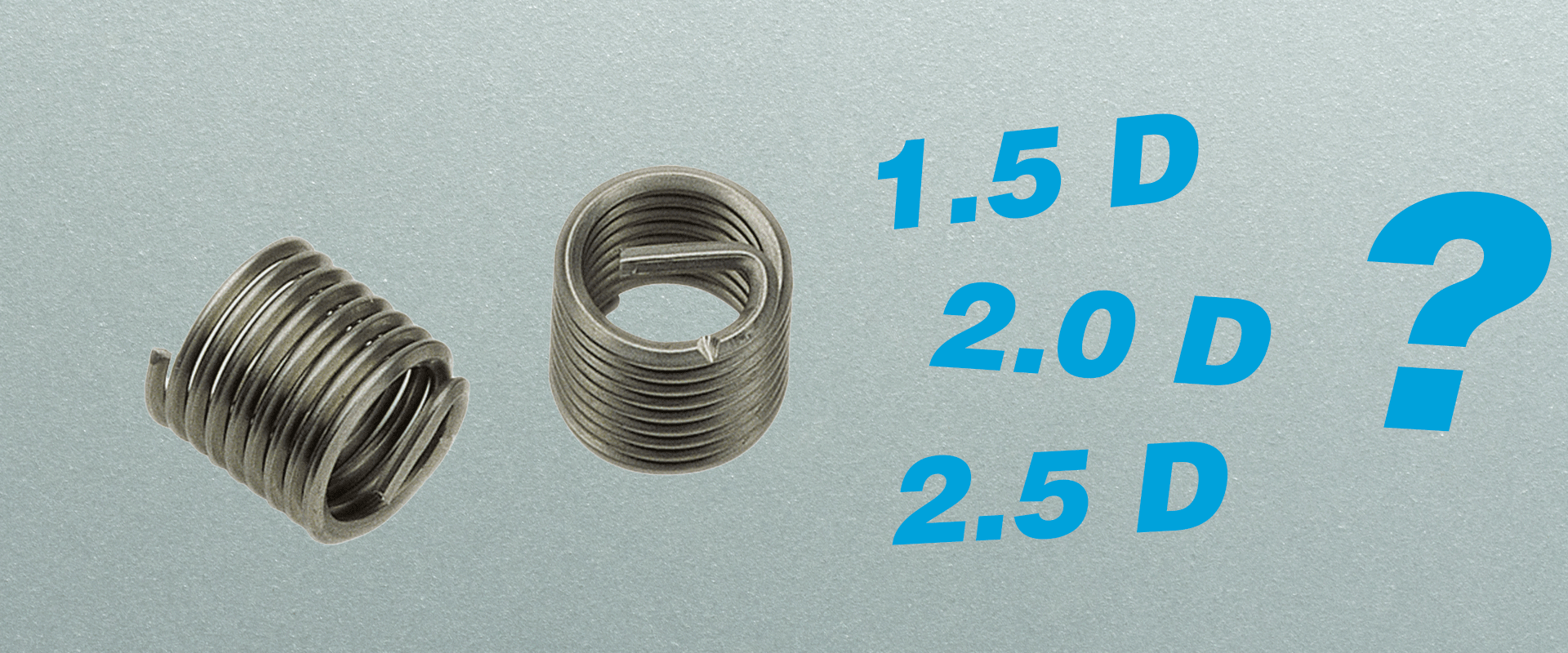

Understanding the meaning of “1.5xD” for thread inserts

The designation “1.5xD” describes the ratio between the length of the thread insert and its nominal diameter in the installed state. “D” stands for the nominal diameter of the thread, and the factor “1.5” indicates the length ratio.

A practical example illustrates this: For a M10 thread insert labeled 1.5xD, the actual thread length in the installed state is 15 mm (10 mm × 1.5 = 15 mm). At V-COIL, we offer thread inserts in various length ratios – from 1.0 D to 3.0 D.

Important technical aspects of length measurement

When working with thread inserts from V-COIL, two essential technical aspects must be considered that affect the actual length:

Length variation due to installation: The specified length of the thread inserts refers exclusively to the installed state. Before installation, the coils of the thread inserts are often closely wound. When screwed into the receiving thread, small gaps form between the individual coils. This effect causes the inserts to stretch slightly and become longer after installation than they were before. V-COIL thread inserts are designed to reach the exact specified length once installed.

Consideration of lead-in and lead-out chamfers: Another important aspect is the presence of lead-in and lead-out chamfers on threads. These technical chamfers must not be exceeded by the thread inserts. For this reason, V-COIL thread inserts are manufactured slightly shorter than the theoretically calculated length.

Conclusion: The right length makes the difference

Correctly interpreting length specifications like “1.5xD” is essential for the successful use of thread inserts in thread repair.

The key takeaways summarized: The length specification refers to the installed state, thread inserts slightly expand during installation, and considering thread chamfers is crucial for a professional installation.

For optimal results in your thread repair, we recommend taking both the mechanical requirements and the design conditions into account. VÖLKEL Threading Solutions supports you with precise product specifications and comprehensive technical support.

Discover our complete range of threading tools and benefit from the experience of one of the industry’s leading manufacturers. Contact us for personalized advice tailored to your specific application requirements.