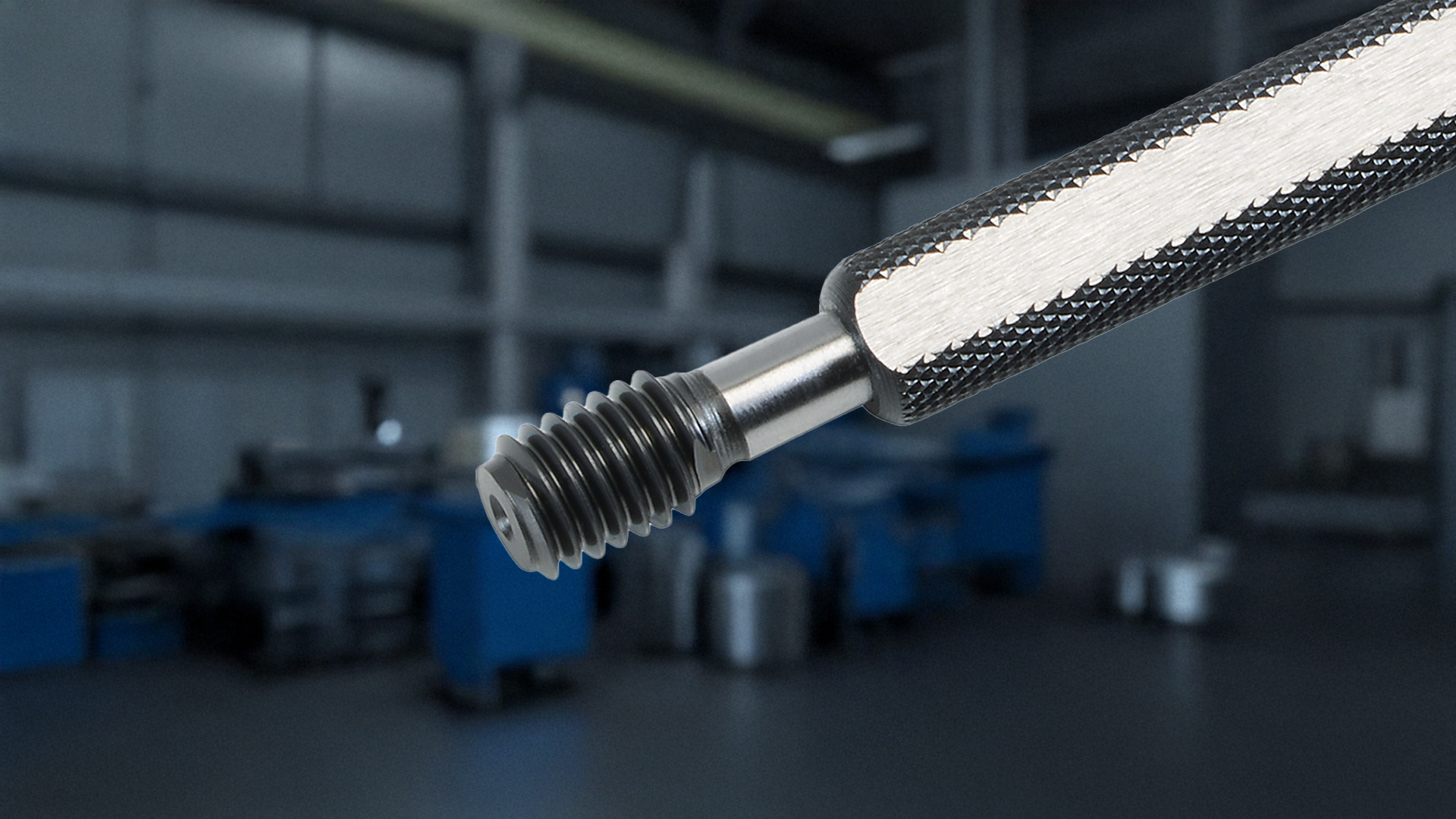

Thread Tap Tolerances at a Glance: Differences, Applications and Recommendations

Whether in industrial production, mechanical engineering or repair work – a precise internal thread is the foundation of a reliable screw connection. What many underestimate: the tolerance class of the thread tap has a decisive influence on how well the screw and the thread will match later. In practice, this means: less scrap, better fit, longer tool life and higher process reliability.

At VÖLKEL Threading Solutions, we not only offer a wide range of metric taps, but also different tolerance classes to ensure the optimal result for each application.

What Are Thread Tap Tolerances?

Thread tap tolerances define the permissible deviation range of an internal thread produced by a tap. In other words, they determine how tight or loose a thread is relative to the nominal size.

For metric internal threads, these tolerances are defined in ISO 965 / DIN 13.

Designations such as “6H” consist of two elements:

Number → size of the tolerance (smaller = tighter)

Letter → position of the tolerance zone (H = no fundamental deviation; G = tolerance shifted into the plus direction)

In short: The tighter the tolerance, the more precise the screw connection – the wider the tolerance, the more room there is for coatings, rough surfaces or difficult materials.

Practical Relevance

Why does the tolerance class matter so much?

Fit accuracy: Screws should engage without excessive force but must not wobble.

Surface treatments: Coatings such as galvanizing require “more space”.

Process reliability: Tight tolerances minimize scrap in precision components.

Ease of assembly: Threads that are too tight can cause assembly problems.

Typical Problems & Challenges

Users often encounter:

Screws fit too tightly or not at all

After coating, the thread becomes too tight

Too much play in applications with vibration

Uncertainty about the correct tolerance class

This is where different tolerance classes come in – and VÖLKEL offers the full range.

VÖLKEL Tolerance Classes and Their Advantages

6H (ISO2) – The Universal Standard

6H is the standard tolerance for metric internal threads. It offers:

High accuracy of fit

Universal applicability

Excellent assembly characteristics

Ideal for most industrial applications.

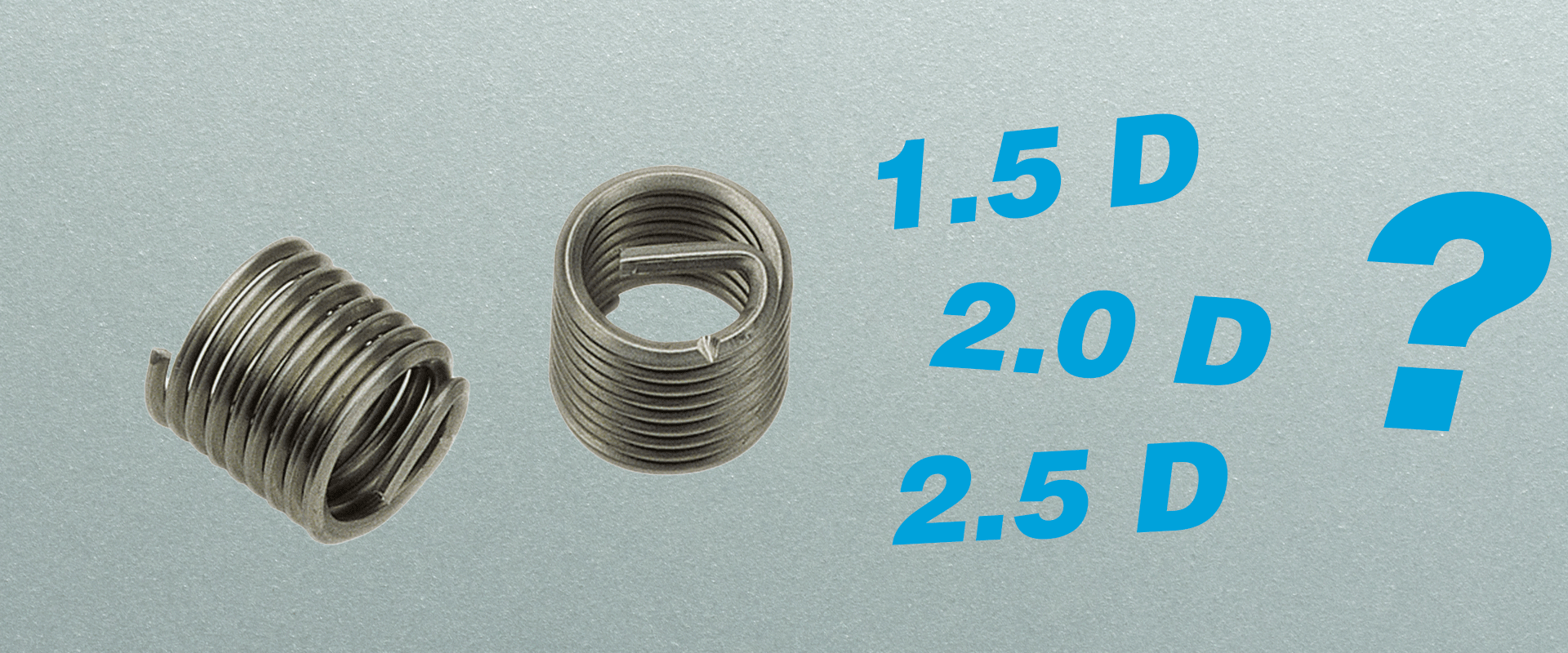

4H (ISO1) – When Precision is Critical

Tolerance class 4H produces a particularly tight thread. Advantages:

Minimal play

Very high dimensional accuracy

Ideal for precision parts, toolmaking and mould making

6G and 7G – More Clearance for Coatings

When components are coated or surface-treated after tapping, larger tolerance zones are essential. Classes 6G and 7G offer:

Enough room for coating thicknesses

Reliable assembly after coating

Less scrap in electroplating processes

+0.1 mm – For Heavy Coatings Such as Galvanizing

For very thick layers – such as hot-dip galvanizing – standard tolerances are no longer sufficient. Oversized taps (+0.1 mm) ensure that the thread remains within tolerance even after coating.

Applications of the Different Tolerances

Series production → 6H or 4H for precise results

Repair & rework → 6G/7G when coating will follow

Heavy coating / galvanizing → +0.1 mm

Fine mechanics & precision components → 4H

Crafts & mechanical engineering → typically 6H

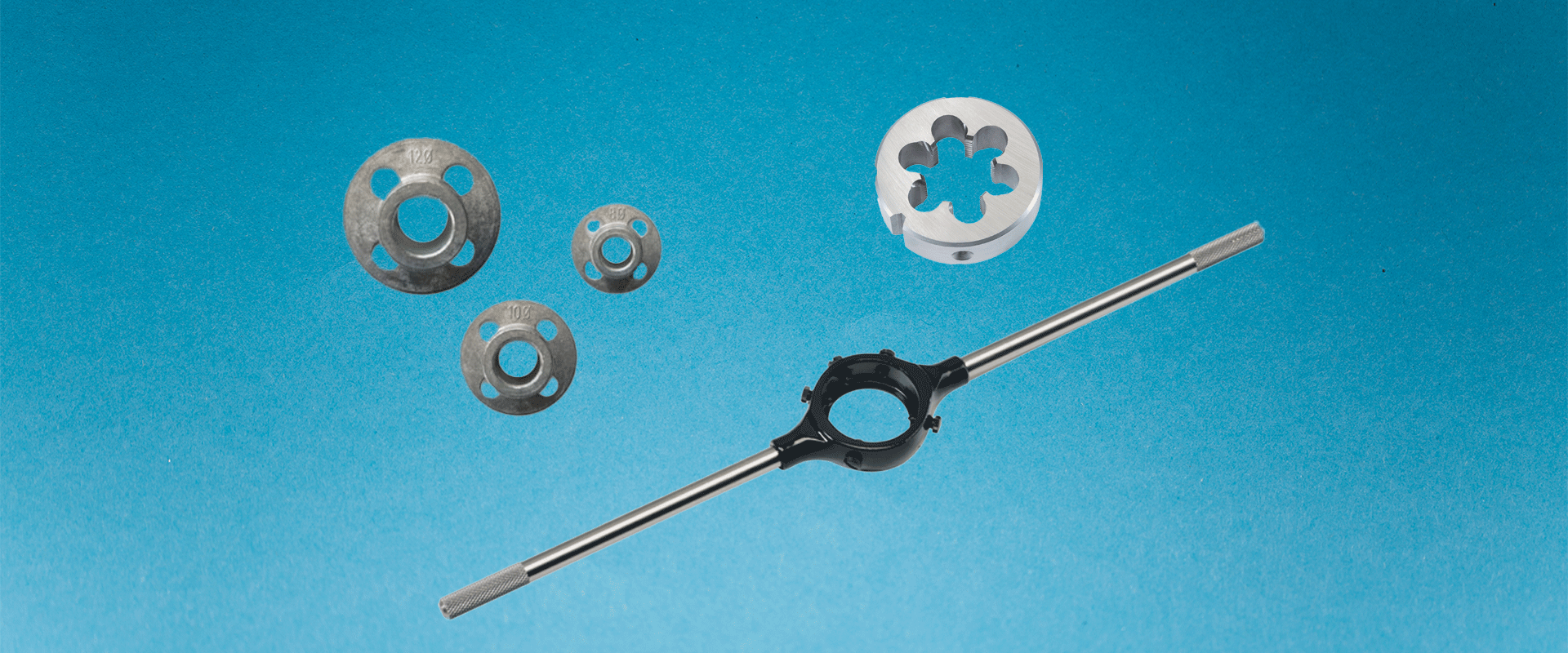

VÖLKEL offers the right tools in HSS, HSS-E, coated or uncoated – always available from stock.

Available from Stock

Many of the tolerance variants mentioned are available directly from VÖLKEL’s warehouse.

From 4H to 6H and +0.1 mm – we deliver quickly, reliably and worldwide.

➡ Browse the VÖLKEL range now and find the right tap!

Conclusion

Thread tap tolerances are a key factor for the accuracy and functionality of a screw connection. Whether tight precision fits, clearance for coatings or robust series production – VÖLKEL offers the right tools for every requirement.