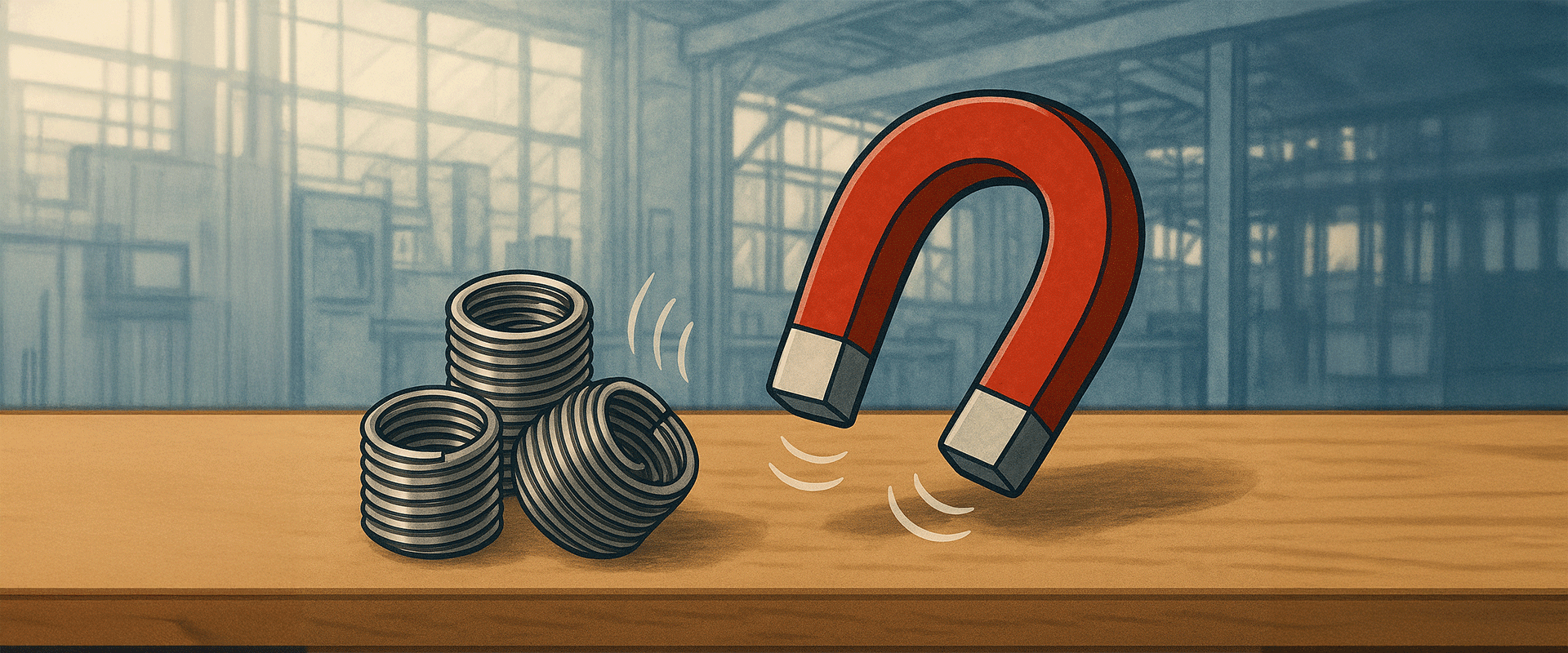

Why are stainless steel thread inserts magnetic?

In daily work with threading tools, surprising phenomena occasionally occur – one of them concerns the magnetizability of stainless steel. Especially with high-quality thread inserts made of non-magnetic stainless steel, users sometimes find: the insert is attracted to a magnet. But how is that possible?

In the following article, we explain why this behavior in V-COIL thread inserts is not a defect, but a special feature of the material.

Why are V-COIL thread inserts magnetic even though they are made of non-magnetic stainless steel?

V-COIL thread inserts are made from high-grade stainless steel 1.4301 – also known as V2A. In its original form, this material is non-magnetic. It offers excellent corrosion resistance, high strength, and very good workability – ideal properties for manufacturing precision thread inserts.

Using state-of-the-art manufacturing processes, VÖLKEL transforms this stainless steel into high-quality V-COIL thread inserts that ensure durable and reliable threaded connections. Among other things, they are used to repair damaged internal threads or to increase the load capacity in lightweight metal constructions – a major benefit for mechanical engineering, toolmaking, and many other industrial applications.

Nevertheless, many users are surprised to find that V-COIL thread inserts react magnetically, even though the base material is technically non-magnetic according to material specifications. How can this be explained?

The answer lies in the manufacturing process: during the forming of the stainless steel wire into its spiral shape, plastic deformation occurs. This changes the internal structure of the material – resulting in what is known as strain-induced martensite. This structural transformation can cause the stainless steel to exhibit a slight magnetic reaction, even though the chemical composition of the material remains unchanged.

This means: the magnetic properties are not a sign of inferior material but are instead the result of the technically necessary forming process. The insert still meets all requirements for strength, corrosion resistance, and precision – with the small side effect that it may respond slightly to a magnet in certain cases.

Conclusion: Magnetic? Yes. Problematic? No.

The slight magnetizability of V-COIL thread inserts is not a sign of inferior quality – but rather the result of the precise processing of a high-quality material. The products are made of non-magnetic stainless steel 1.4301, which can temporarily exhibit magnetic behavior due to plastic deformation.

With V-COIL thread inserts, users benefit from maximum precision, reliability, and durability.