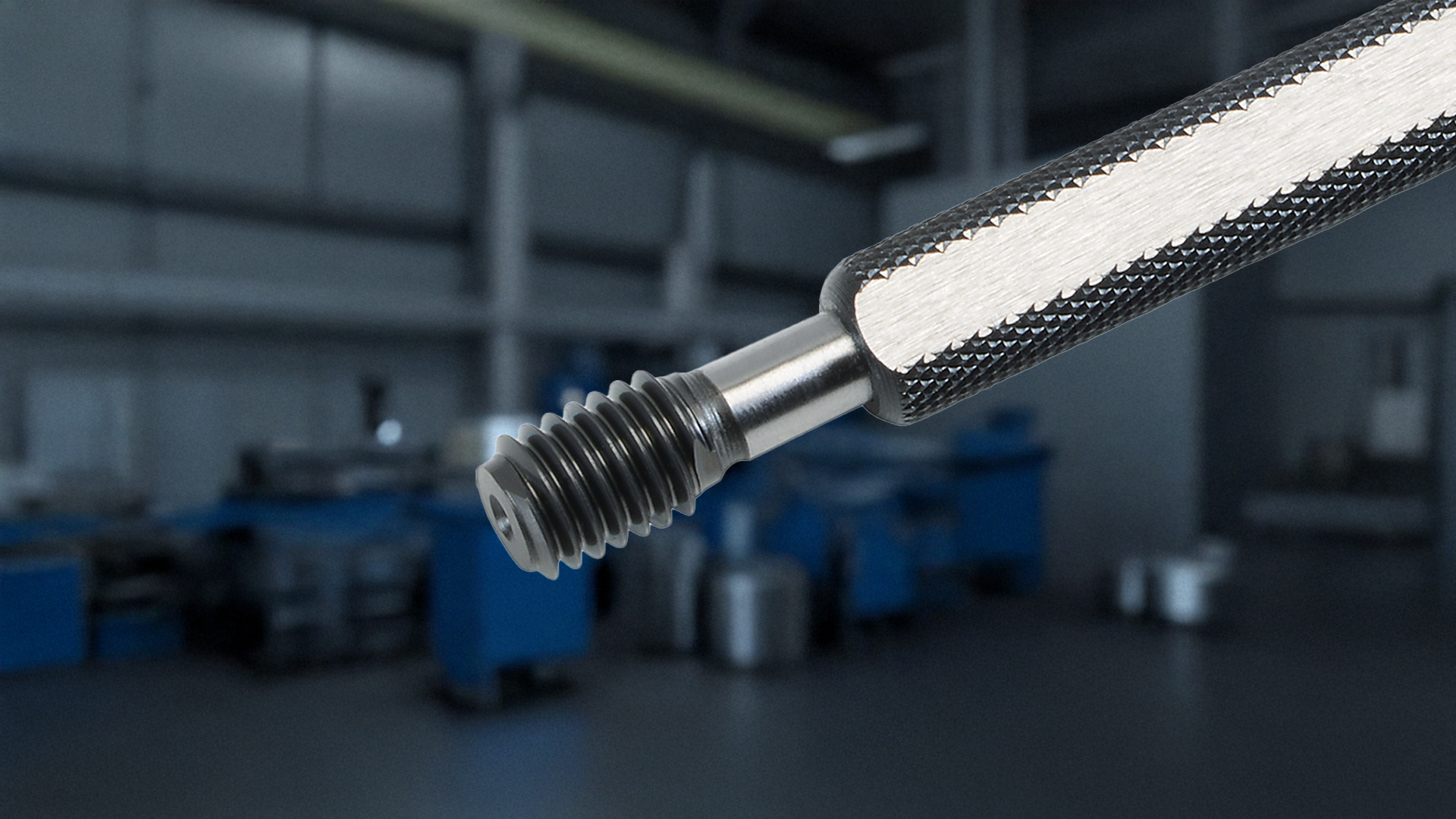

VÖLKEL Combined Tap Bit: Drill, Tap & Deburr in One Step

Why combo bits are so practical—especially for installation and maintenance

On site, time is rarely predictable, space is often limited, and the nearest workshop can be far away. But internal threads still need to be produced cleanly and reliably. In practice, that usually means: drill the tap hole, change tools, start the tap, change tools again, deburr. Each of these steps interrupts workflow and increases the risk of mistakes.

Especially under real-world conditions—poor accessibility, awkward body position, changing materials—this classic sequence quickly becomes inefficient. Threads started at an angle, forgotten lubrication, or unnecessary tool changes cost time, patience, and in the worst case rework.

That’s exactly where the need arises for a solution that simplifies the process without compromising function.

The solution: VÖLKEL Combined Tap Bits

The VÖLKEL Combined Bits are designed specifically for mobile use. They enable drilling the tap hole, tapping, and deburring in a single operation and can be swapped quickly thanks to the 1/4" bit holder.

Instead of several tools, one single bit is enough. Insert, position, cut the thread—without breaking the workflow. That’s what makes the difference between a technically clean solution and a tool that genuinely helps in everyday installation work.

What is a Combined Tap Bit?

A Combined Tap Bit is a combined tap bit that combines three work steps in one tool:

Drilling the tap hole

Tapping

Deburring the hole edge

Everything happens in a single operation. The tool has a 1/4" hex shank and can be used directly in cordless drills or hand drills with forward and reverse. Use on stationary drilling machines is also possible, provided the work is carried out cleanly.

This isn’t a gimmick, but a clearly functional solution for typical installation and service applications where speed, clarity, and repeatable results matter.

Where are Combined Tap Bits used?

The typical application area for Combined Tap Bits is wherever flexibility matters more than maximum process optimization:

Installation work and plant construction

Maintenance and service calls

Trade fair construction and on-site installations

Workshop tasks and small batches

Combined Tap Bits are particularly useful for through threads in common materials, when you need to switch quickly between different thread sizes and the working environment isn’t ideal.

Technical key data at a glance

Use with cordless and hand drills (forward/reverse)

Also suitable for stationary drilling machines

Materials: steel, non-ferrous metals, and plastics up to 600 N/mm² tensile strength

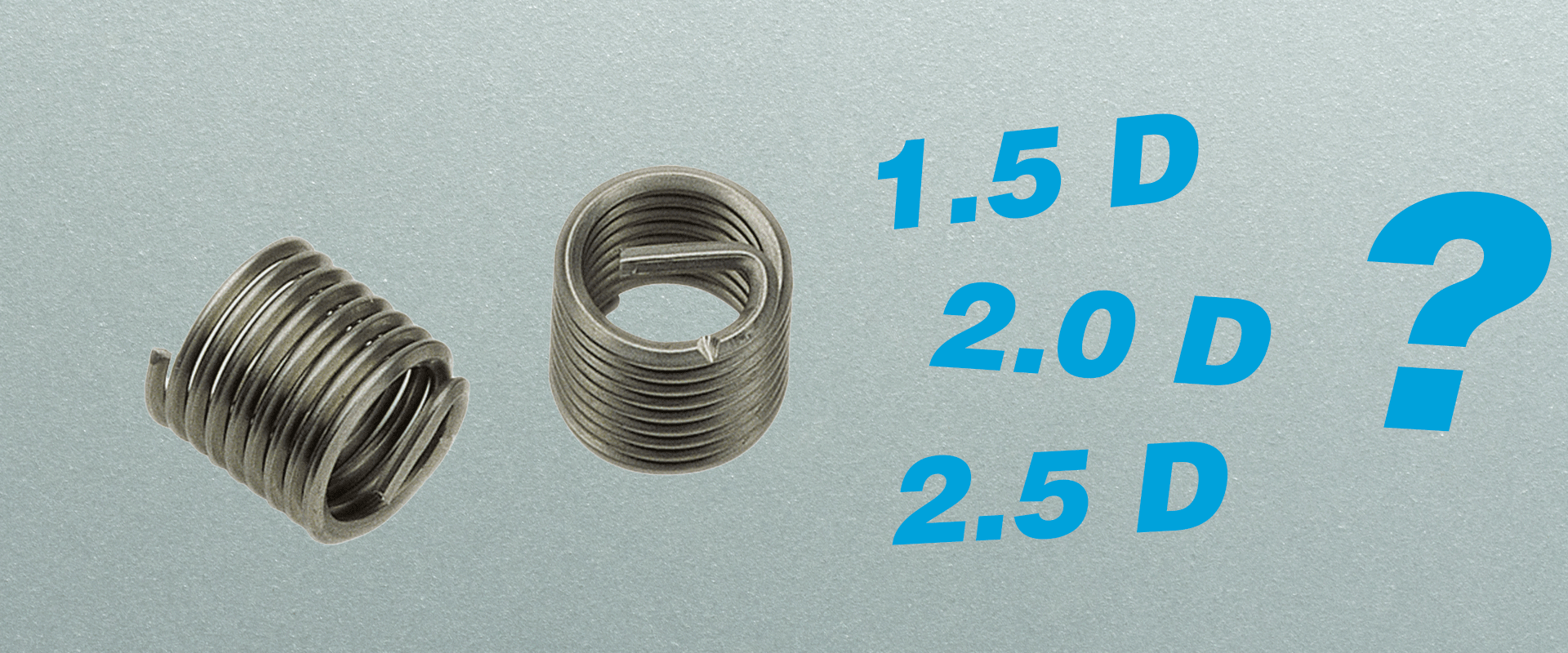

Through threads only, max. 1×D thread depth

Material: HSS

Metric sizes optionally available ex stock with TiN coating

The TiN coating reduces friction, improves tool life, and ensures more consistent cutting performance—especially in repeated applications.

Available dimensions

Metric:

M3, M4, M5, M6, M8, M10

Set: M3–M10 (also TiN-coated)

UNC:

No. 4 to 3/8

Set: No. 8–3/8

UNF:

No. 4 to 3/8

Set: No. 8–3/8

The biggest advantage isn’t in theoretical cutting data, but in everyday work: one tool, one change, one continuous process.

Use cases and best practices

To ensure Combined Tap Bits work reliably, a few simple rules have proven effective:

Secure the workpiece and start cleanly

Work as perpendicular as possible

Low speed, controlled torque

Use cutting oil

When backing out, switch cleanly to reverse

For installation work, repairs, and small batches, this is often the most efficient way to produce internal threads. For deep threads, blind holes, or serial production with maximum process control, the classic method remains superior.

Typical problems and challenges

Combined Tap Bits work reliably—if used correctly. The most common issues are well known and avoidable.

Starting at an angle

Tool axis and hole axis must align. Even small deviations lead to poor thread quality or high wear.

No lubrication

Without cutting oil, friction and temperature increase. That reduces tool life and thread quality.

Speed too high

Tapping is not a high-speed process. Controlled work with feel is objectively better.

Wrong application

Combined Tap Bits are not intended for blind holes or deep threads.

If you ignore these points, you won’t enjoy even the best tool.

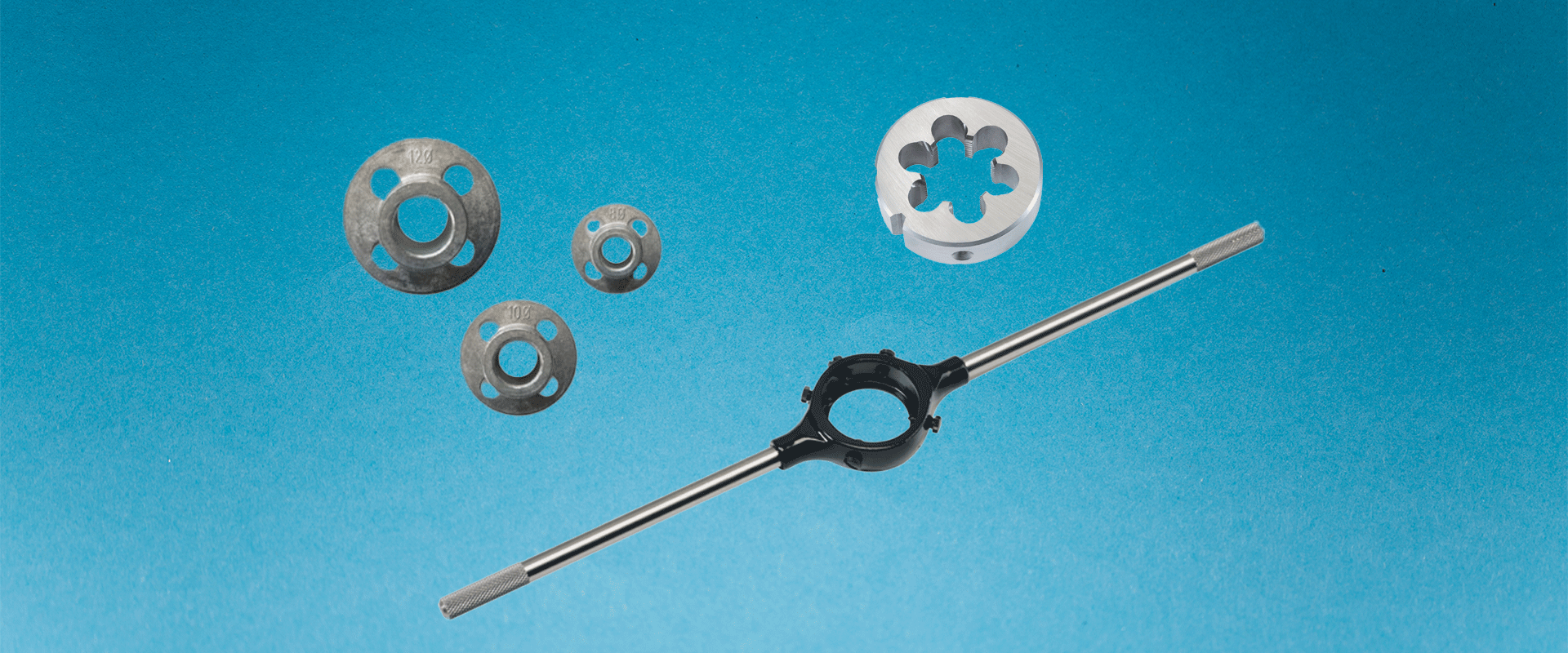

Combined Tap Bit or classic tap?

Combined Tap Bit (e.g., VÖLKEL Combined Tap Bit)

Fast, flexible, minimal setup. Ideal for through threads, installation, and service. Limited depth, not for blind holes.

Classic tap

More control, greater thread depths, better for serial production and demanding processes. But it requires more tools and more time.

In short: Combined Tap Bits are the pragmatic solution; classic taps are the precise one.

VÖLKEL Combined Tap Bits — available ex stock immediately

When threads need to be cut quickly, flexibly, and directly on site, VÖLKEL Combined Bits are a very practical solution. The common metric sizes and sets in particular are designed for short response times—including TiN-coated versions available ex stock.

Conclusion

Combined Tap Bits are not a high-end solution for every threading task, but they solve a very specific practical problem: time loss and unnecessary tool changes for through threads. That’s exactly what VÖLKEL Combined Bits are made for. For installation, maintenance, and any application where flexibility matters, they are often the most sensible choice.

FAQ: Frequently asked questions about Combined Tap Bits (quick answers)

Can I cut threads with a cordless screwdriver?

Yes—as long as it has forward/reverse and you work at low speed with controlled torque. A straight start and lubrication are important.

Are Combined Tap Bits suitable for blind holes?

Generally no. Combined Tap Bits are designed for through threads.

How deep can I cut with them?

Maximum 1×D thread depth. For deeper threads, you need a different solution.

Do I really need cutting oil?

In steel, practically always. It reduces friction and wear and noticeably improves thread quality.

Which materials can I work with?

Steel, non-ferrous metals, and plastics up to 600 N/mm² tensile strength as designed.