HSSG, HSSE or HSSE VAP? VÖLKEL shows which hand tap is the right one.

Anyone who has ever cut an internal thread by hand knows the problem: The result often looks rough, the tap jams, or even breaks. The right tool is therefore crucial for precision, tool life, and the final result. With VÖLKEL hand taps you have the right solution for every material – from standard steel to high-strength alloys. This way you avoid frustration, save time, and achieve clean, accurate threads.

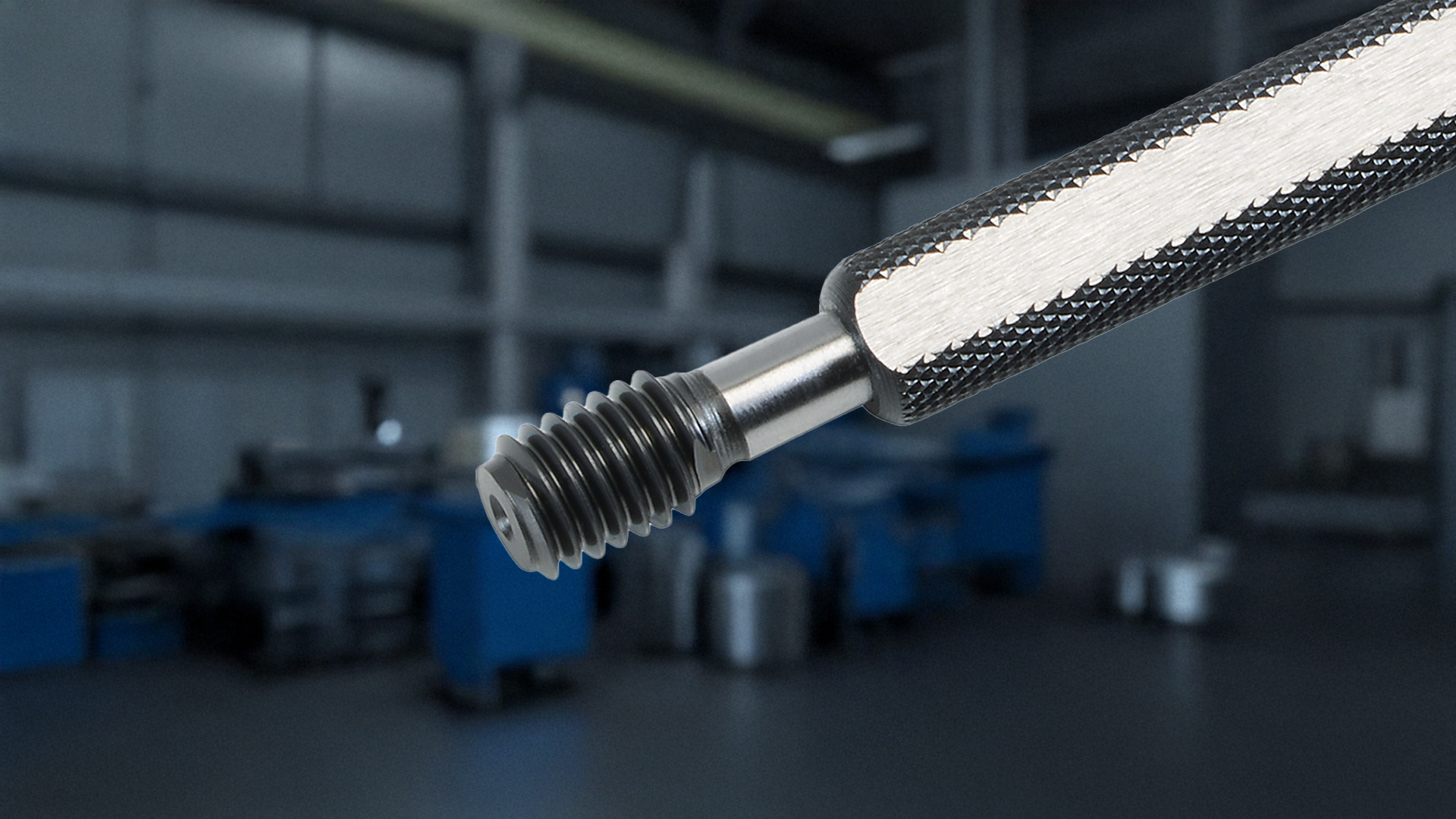

What is a hand tap?

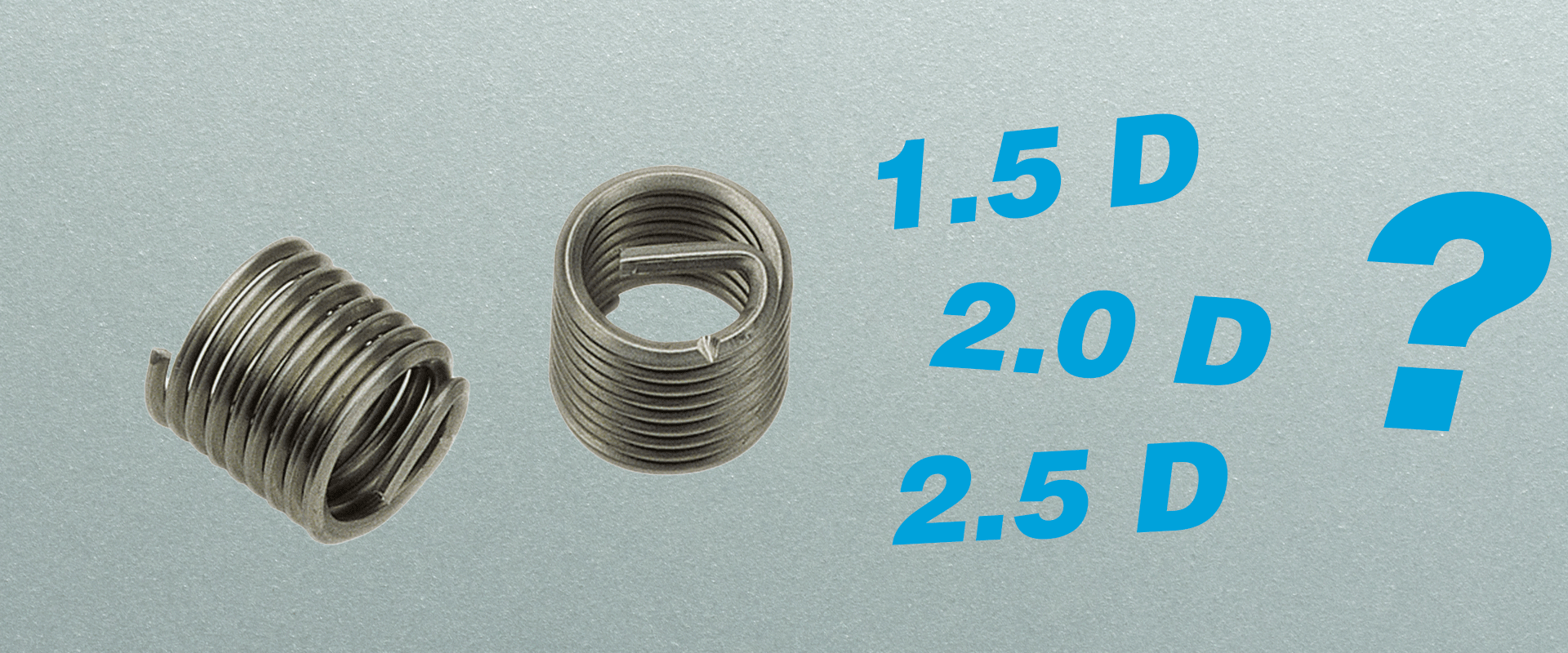

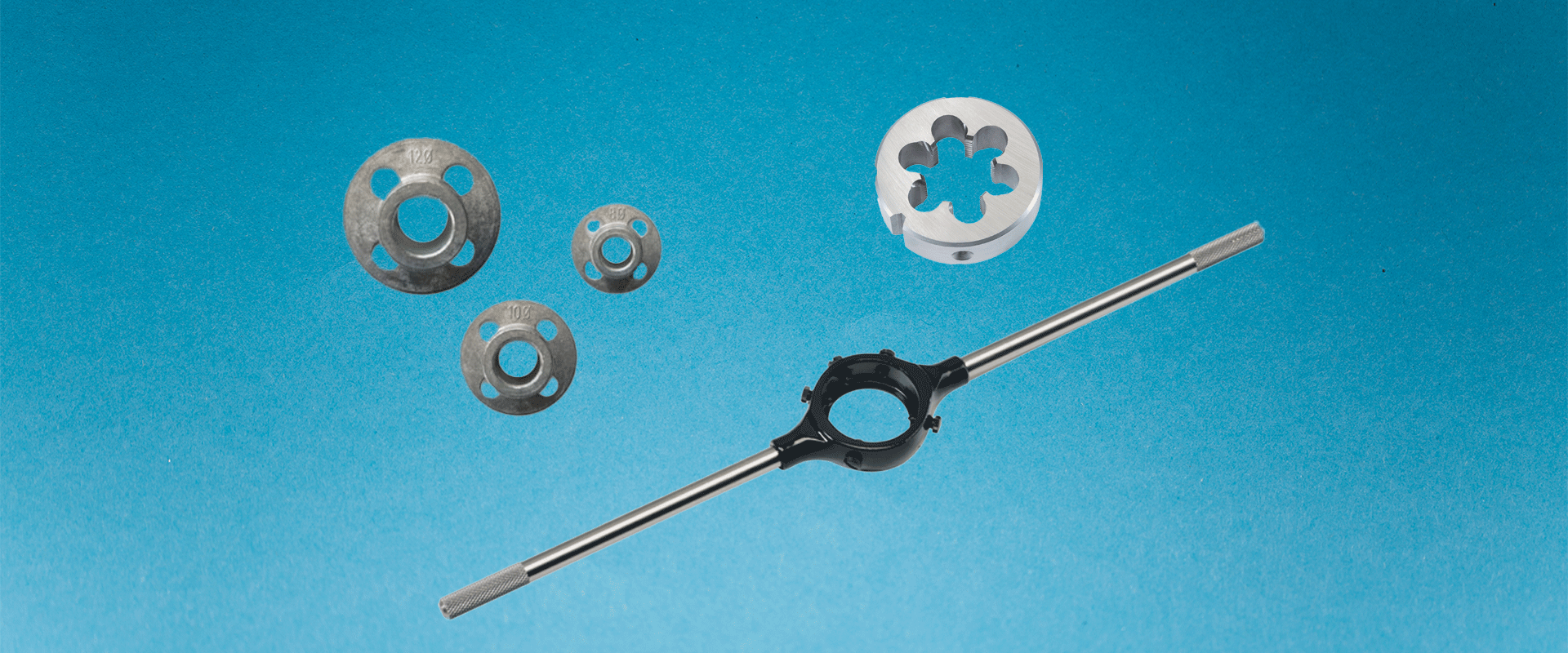

A hand tap is a precision cutting tool used to cut threads by hand into pre-drilled core holes. It is usually clamped in a tap wrench and used in three steps: taper tap, intermediate tap, and finishing tap. The three-piece set ensures reduced cutting load and produces a clean, precise thread.

Fields of application – from craftsmanship to repair

Hand taps are used wherever threads need to be cut or repaired precisely and reliably by hand: for example in repairs, in crafts, for custom-made parts – and even in industrial production when precise manual work is required.

Typical challenges in thread cutting

Many users are familiar with these problems:

- Broken taps in tough materials

- Rough or inaccurate results

- Fast tool wear

- Difficulty centering in the pilot hole

VÖLKEL offers you exactly the right hand taps – optimized for every material and every challenge.

The VÖLKEL Variants at a Glance: HSSG, HSSE & HSSE VAP

Our HSSG hand taps are the first choice for unalloyed to low-alloy steels, non-ferrous metals and aluminum.

- Material: High-quality, ground high-speed steel (HSS)

- Advantages: Precise cutting, long tool life, clean threads

- Application: Ideal for standard workshop and assembly applications

HSSE hand taps – for demanding materials

When things get tougher, the HSSE hand taps come into play.

- Material: HSS with 5% cobalt content

- Advantages: Higher hot hardness, stable cutting in stainless steels, quenched and tempered steels, and tough materials

- Application: Perfect for applications where conventional HSSG taps wear out quickly

HSSE VAP hand taps – for maximum precision

For particularly hard, high-alloy, or wear-resistant steels, we recommend our vaporized HSSE hand taps.

- Special feature: Pilot nose on the taper tap for accurate centering

- Vaporized surface: Improves lubricant adhesion, reduces friction, and increases tool life

- Application: For high-strength materials and whenever maximum dimensional accuracy is required

Practical tip: Use the right cutting fluid

To achieve optimal results, it is recommended to use a suitable cutting oil. This protects both the tool and the workpiece and ensures an even cut.

Versatile – more than just for new threads

Hand taps are not only suitable for cutting new threads, but also for rethreading damaged threads or post-processing. This makes them an indispensable tool in maintenance and repair.

Immediately available from VÖLKEL

All our hand taps are available from VÖLKEL directly from stock – in various sizes and practical sets. So you can start immediately without any delay.

Conclusion

With the right hand taps from VÖLKEL, thread cutting is no longer a problem.

- HSSG for standard materials

- HSSE for tough, hard-to-machine materials

- HSSE VAP for the highest requirements

Rely on VÖLKEL expertise – for precise, reliable, and durable results.