Checking STI Threads Correctly – Why Standard Thread Gauges Are Unsuitable Here

Why thread inspection matters

Whether an internal thread will perform reliably depends on its dimensional accuracy. In practice, deviations often only become visible late in the process: screws do not thread in smoothly, thread inserts do not seat correctly, or components fail final inspection. Thread inspection addresses exactly this point. What is sometimes perceived as an optional step in day-to-day work is, strictly speaking, a core element of quality assurance in manufacturing, repair, and maintenance.

This is especially true when threads are not used directly in the base material, but are reinforced or repaired with wire thread inserts such as V-COIL. In these cases, a so-called receiving thread is created first, and it must meet precisely defined dimensions. If this thread deviates even slightly, it has an immediate impact on function, load capacity, and repeatability of the subsequent screwed joint.

What are STI threads—and why standard gauges do not work here

When wire thread inserts such as V-COIL are used, the internal thread is intentionally cut larger than a standard thread. This special size is referred to as an STI thread. STI stands for Screw Thread Insert and describes a thread profile designed specifically to accept a wire thread insert.

In practice, this leads to a common issue: standard thread plug gauges are not suitable for these receiving threads. They check the wrong size and therefore do not provide a reliable statement about the actual gauging accuracy of the STI thread. Anyone who still uses standard gauges in this context risks incorrect assessments, unnecessary scrap, or later assembly issues. For correct inspection, special STI precision thread plug gauges must be used, matched to the required thread size.

Typical challenges in practice

In daily manufacturing and maintenance work, similar challenges repeatedly arise around STI threads:

Is the cut receiving thread fully dimensionally accurate?

Was the thread cutting process clean, or are there tolerance deviations?

Can the thread be checked reliably without complex measuring technology?

Can the inspection be carried out safely by different personnel?

Especially in repairs or small batch production, there is often no time or equipment for complex measurement methods. At the same time, the demand for reproducible quality increases—regardless of whether the thread was produced manually or by machine.

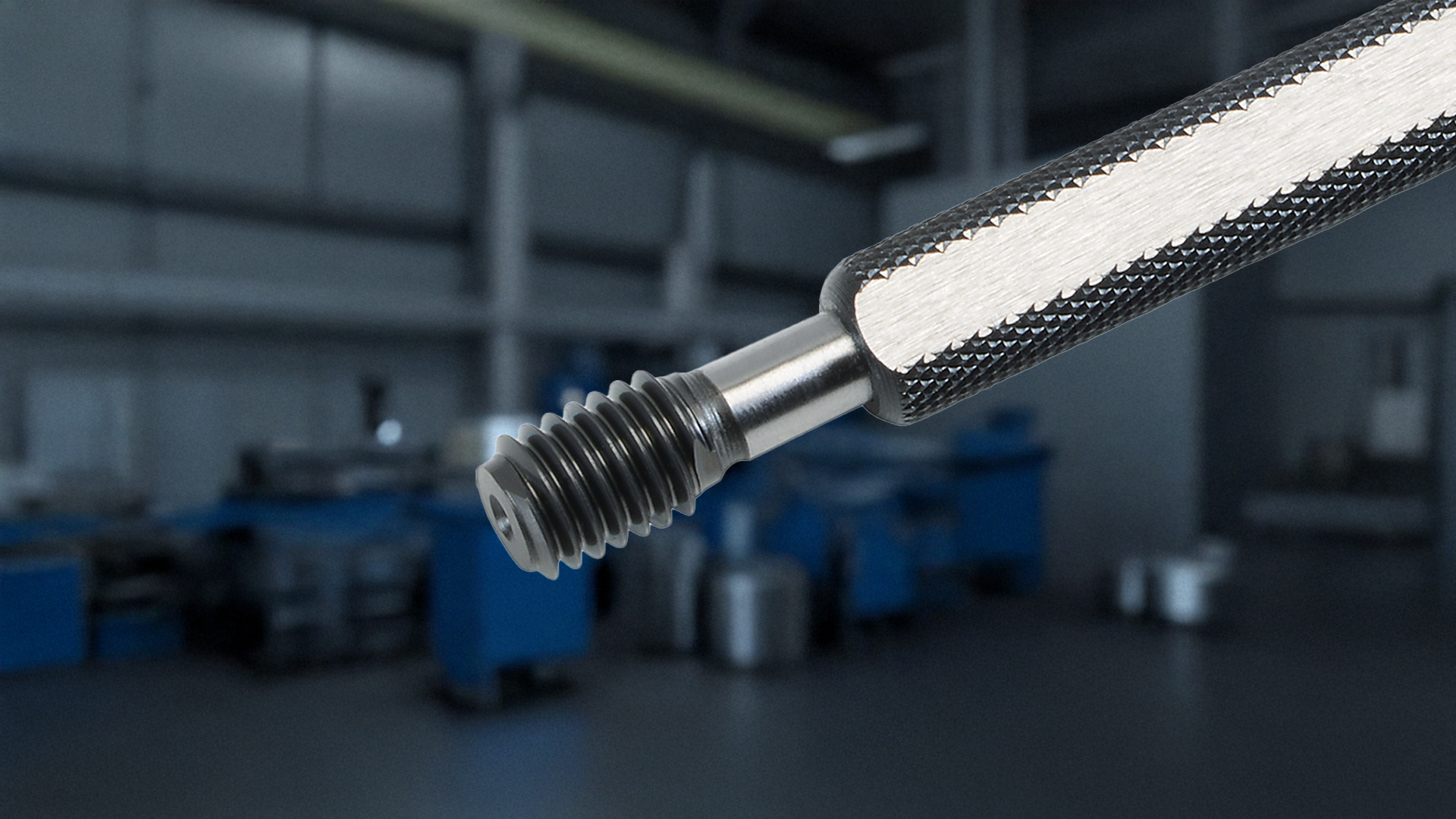

The solution: V-COIL STI precision thread plug gauges

V-COIL STI precision thread plug gauges address these challenges in a practical way. They were developed specifically for inspecting receiving threads for wire thread inserts and enable a quick, safe assessment of the thread’s gauging accuracy directly on the component.

Operation is deliberately straightforward: the plug gauge is screwed into the cut STI thread. Depending on the design, the Go/No-Go principle reliably indicates whether the thread is within permissible tolerances. No complex measuring equipment or special training is required.

Key benefits of STI precision thread plug gauges at a glance

The plug gauges offer several clear advantages:

Easy handling

Operation is self-explanatory and suitable even for non-specialist personnel.High accuracy

Precision manufacturing ensures reliable results and reproducible quality.No special measuring equipment required

No additional metrology equipment is needed, reducing cost and simplifying processes.Fast inspection

Checking directly on the workpiece saves valuable time in production.Safety before installation

Errors in the receiving thread are detected before the thread insert is installed.

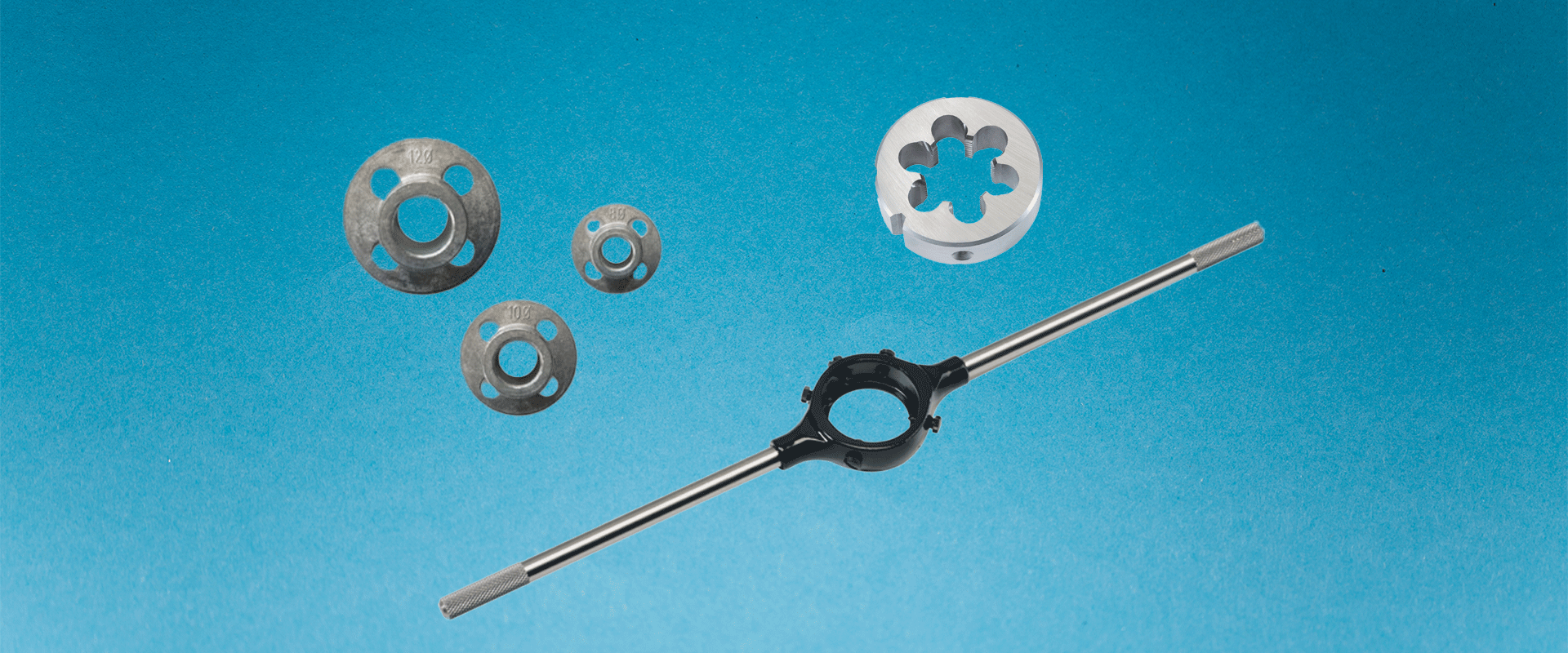

After installing the wire thread insert, the finished internal thread can then be inspected as normal using a standard thread plug gauge for standard threads. This ensures quality is clearly secured in both process steps.

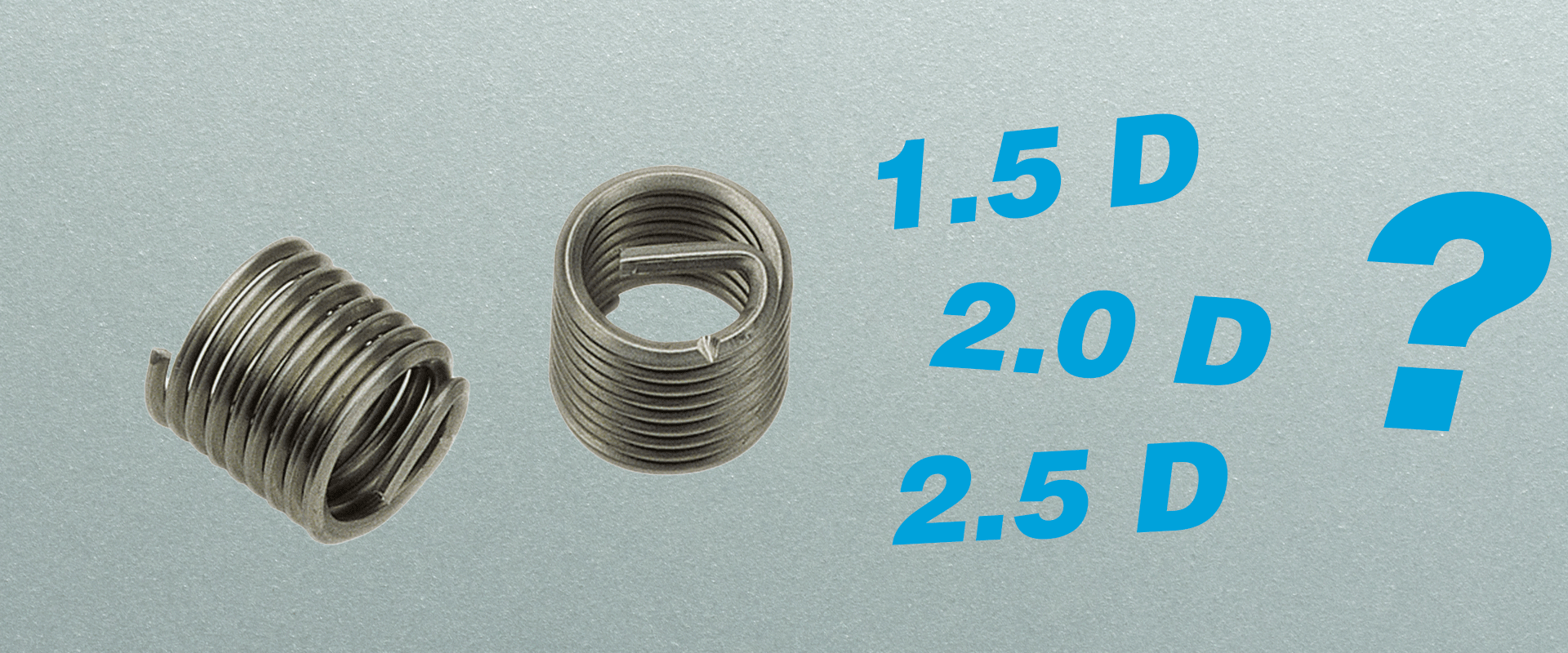

Broad range for different thread types

VÖLKEL offers STI precision thread plug gauges for a wide variety of common thread types, including:

M (metric)

Mf (metric fine)

UNC

UNF

UNx8

BSW

BSF

G (BSP) pipe threads

This makes it possible to cover both metric and inch-based applications reliably—from single repairs to series production.

Calibration and quality assurance

For applications with increased documentation and traceability requirements, the STI precision thread plug gauges can also be supplied with a factory calibration certificate on request. This supports integration into existing quality assurance systems and provides additional confidence during audits and inspections.

Conclusion

Only correctly inspected STI threads ensure that screwed joints with wire thread inserts function reliably over the long term. With V-COIL STI precision thread plug gauges, a simple, precise, and proven tool is available to enable quality assurance without unnecessary effort.