Thread Plug Gauges with DLC Coating – Maximum Precision and Service Life

Thread Plug Gauges with DLC Coating – Maximum Precision and Service Life

Whether in series production, the quality laboratory, or tool manufacturing – thread inspection is a crucial step for the quality of every component. Only a correct thread ensures that screw connections hold securely and components function reliably over the long term.

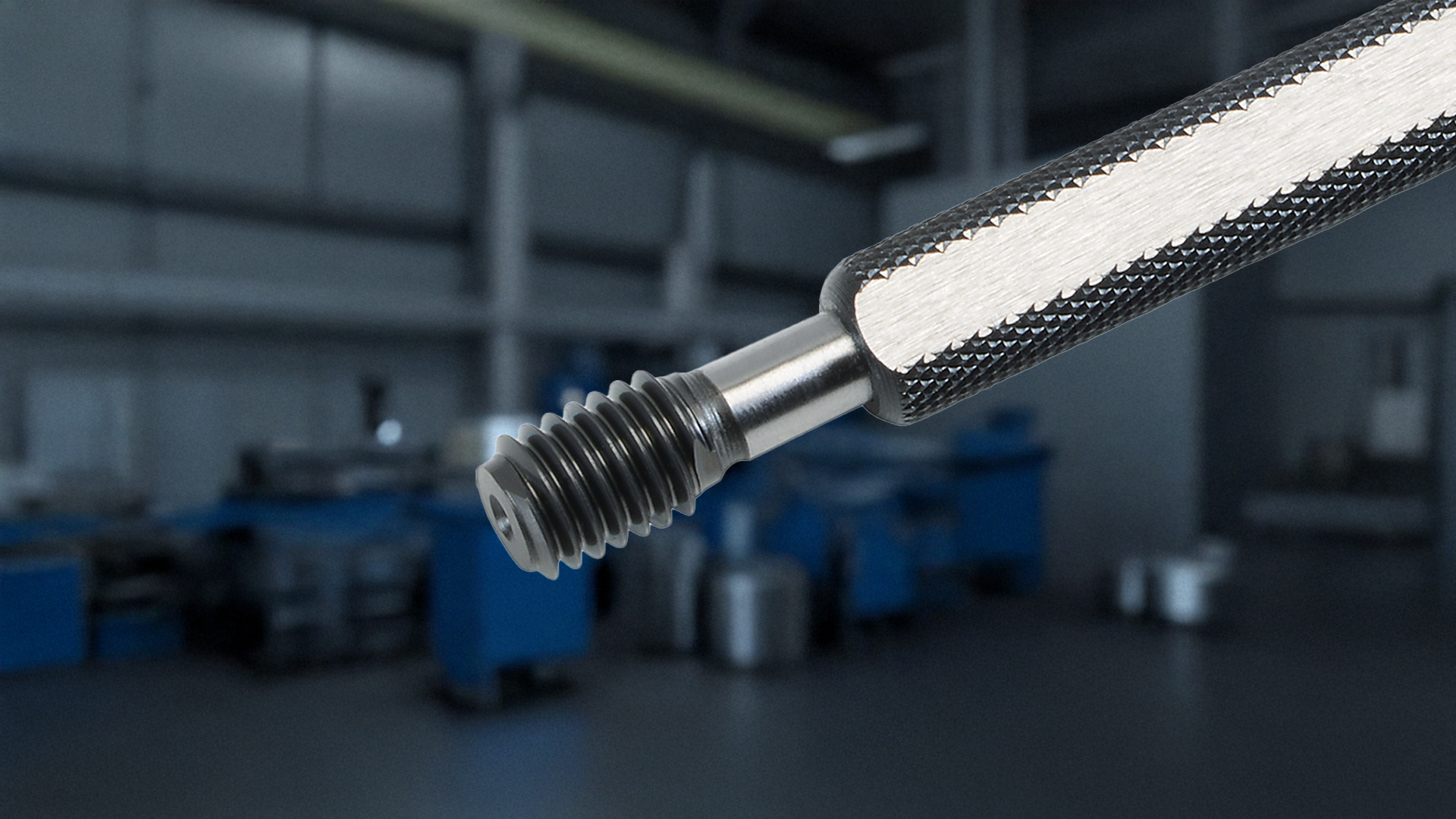

With thread plug gauges for metric standard threads from M3 to M24, VÖLKEL Threading Solutions offers a high-end solution where the GO side (Gut-Seite – “Good side”) is optimally protected by a DLC coating – for precise results and the highest tool life.

What is a DLC Coating?

DLC stands for “Diamond Like Carbon” – a diamond-like carbon layer.

This ultra-thin but hard coating combines the best properties of diamonds (hardness, wear resistance) and graphite (sliding ability/slipperiness).

The result: a nearly friction-free surface with exceptional resistance to abrasion and corrosion.

In VÖLKEL’s thread plug gauges, the DLC coating is specifically used where it offers the greatest benefit – on the GO side. This side is fully screwed into the workpiece during the inspection process and is thus exposed to the highest mechanical stress.

Why Thread Plug Gauges with DLC Coating Are Convincing in Use

In practice, every detail determines the precision and service life of a testing tool.

With increasing use, uncoated thread plug gauges gradually show signs of wear – especially with small threads or hard materials like stainless steel. The DLC coating prevents exactly that: its smooth, hard surface reduces friction, protects the threads, and ensures a significantly longer service life – while maintaining dimensional accuracy.

Typical Challenges in Thread Inspection

Wear of the GO side with very frequent use

Faulty test results due to damaged thread profiles

Corrosion during long-term storage or in humid environments

Where precision counts to the thousandth, even minimal wear can quickly become expensive.

Your Solution from VÖLKEL: Thread Plug Gauges with DLC Coating for Precise Results

With the DLC-coated thread plug gauges, VÖLKEL offers you a durable and precise solution for daily quality control.

The Advantages at a Glance:

Extremely high surface hardness up to 3,500 HV – for maximum wear resistance and long service life

Temperature resistant up to 350 °C – ideal even for demanding application conditions

Very low sliding friction (coefficient of sliding friction: 0.08–0.1) – for smooth and precise inspection

High resistance to abrasion – reliably protects the threads from wear

Corrosion resistant – even in humid or aggressive environments

Long-term dimensional accuracy – consistently precise test results over many inspection cycles

Available for metric standard threads from M3 to M24 – including an optional measurement certificate

Every gauge is manufactured with the highest precision and is optionally available with a factory certificate – including the DLC variant, of course.

Application Possibilities – From Workshop Routine to Series Production

DLC-coated thread plug gauges are used wherever testing equipment is used intensively and the highest precision is required.

Typical applications include:

Series production and final inspection

Measuring rooms and testing laboratories

Quality management in mechanical engineering

Maintenance and repair of threads

Thanks to the significantly extended service life, the investment quickly pays for itself – especially with recurring inspection tasks.

Immediately Available from Stock

Like all standard products from VÖLKEL Threading Solutions, the DLC-coated thread plug gauges are also immediately available from stock in many sizes.

This means: no long waiting times, no custom orders – just order and use them directly.

Conclusion: Small Layer, Big Impact

The DLC coating turns a standard plug gauge into a premium testing tool for the highest demands – durable, low-friction, and absolutely precise.

If you don't want to compromise on thread inspection, a DLC-coated thread plug gauge from VÖLKEL Threading Solutions is exactly the right choice for you.

FAQ – Frequently Asked Questions

What do "GO" and "NOGO" mean?

The GO side must thread in, and the NOGO side must not – that's how dimensional accuracy is checked.

How long does a DLC coating last?

Significantly longer than uncoated plug gauges, especially with frequent use.

Can existing plug gauges be coated?

No, the coating is applied during manufacturing – the gauges are precisely corrected for the layer thickness and are immediately available from stock in many sizes.